Professional Powder Coating Equipment: The coating equipment industry plays a pivotal role in modern manufacturing processes across various sectors, including automotive, aerospace, electronics, and consumer goods. The industry’s significance lies in its ability to enhance the durability, aesthetics, and functionality of products. Coating technologies protect materials from corrosion, wear, and environmental damage, while also offering an array of finishes that appeal to consumer preferences.

In recent years, advancements in coating equipment have led to more efficient, cost-effective, and environmentally friendly solutions. The introduction of Professional Powder Coating Equipment has revolutionized the industry, offering manufacturers the ability to apply durable finishes with precision and consistency. These advancements have made the Coating Equipment Industry a critical component of the global manufacturing landscape

Introduction to Coating Equipment Industry

The coating equipment industry is a cornerstone of modern manufacturing, underpinning a vast array of sectors, from automotive to consumer electronics. The industry encompasses a wide range of technologies and machinery designed to apply protective and decorative coatings to various substrates, ensuring that products not only meet aesthetic standards but also maintain durability and resistance to environmental factors.

In today’s highly competitive global market, the role of coating equipment has become more critical than ever. Manufacturers are constantly seeking ways to enhance the performance and longevity of their products while reducing costs and environmental impact. This demand has driven significant innovation in the coating equipment industry, leading to the development of more advanced, efficient, and sustainable technologies.

One of the most significant advancements in this field has been the evolution of Professional Powder Coating Equipment. Powder coating, a dry finishing process, has become increasingly popular due to its efficiency, environmental benefits, and the superior quality of the finish it provides. Unlike traditional liquid coatings, powder coatings do not require solvents and emit negligible volatile organic compounds (VOCs), making them an environmentally friendly option. The process involves applying a free-flowing, dry powder to a substrate, which is then cured under heat to form a hard, durable finish.

The Coating Equipment Industry is also characterized by its diversity. It includes everything from Spray Coating Equipment used for applying paint or coatings in liquid form, to highly specialized machinery designed for coating glass, metals, plastics, and other materials. This diversity is reflective of the wide range of industries that rely on coating technologies, each with its unique requirements and challenges.

In the automotive industry, for example, coating equipment is essential for applying protective and decorative finishes to vehicles. These coatings not only enhance the appearance of the vehicles but also provide protection against corrosion, scratches, and other forms of wear and tear. Similarly, in the aerospace industry, coatings are critical for protecting aircraft components from extreme temperatures, UV radiation, and other harsh environmental conditions.

Moreover, the Coating Equipment Industry is continually evolving to meet the changing needs of manufacturers. The rise of smart manufacturing and Industry 4.0 technologies has led to the development of more automated and intelligent coating systems. These systems are capable of adjusting their operation in real-time based on data inputs, ensuring optimal performance and reducing waste. Automatism for Coating and Finishing Panels is an example of such advancements, where automation is increasingly being integrated into coating processes to enhance precision, efficiency, and consistency.

In addition to technological advancements, there is a growing emphasis on sustainability within the industry. As environmental regulations become more stringent, manufacturers are seeking coating equipment that minimizes environmental impact. This has led to the development of low-energy curing ovens, water-based coatings, and more efficient application techniques that reduce material waste. Powder Coating Ovens, for instance, have seen significant improvements in energy efficiency, with new models offering faster curing times and lower energy consumption.

Furthermore, the industry has seen the emergence of specialized equipment tailored to meet the demands of specific applications. For example, Glass Coating Machinery is designed to apply coatings to glass surfaces, providing protection against scratches, chemical damage, and UV radiation, while also enhancing the aesthetic appeal of the glass. Similarly, Powder Coating Wash Systems are engineered to ensure that parts are properly cleaned and prepared before coating, which is crucial for achieving a high-quality finish.

In conclusion, the coating equipment industry is a dynamic and essential part of the manufacturing sector, driving innovation and sustainability across multiple industries. The continuous development of new technologies and machinery, such as Professional Powder Coating Equipment, Spray Coating Equipment, and Automatism for Coating and Finishing Panels, is enabling manufacturers to meet the demands of an increasingly competitive market while adhering to stricter environmental standards. As the industry continues to evolve, it will undoubtedly play a critical role in shaping the future of manufacturing.

Types of Coating Equipment

The coating equipment industry encompasses a broad range of technologies, each designed to address specific needs and challenges within different sectors. Understanding the various types of coating equipment is crucial for manufacturers aiming to achieve optimal performance, efficiency, and quality in their production processes. In this section, we will explore some of the most prominent types of coating equipment, including Spray Coating Equipment, Electrostatic Coating Equipment, and specialized powder coating systems.

Spray Coating Equipment

Spray Coating Equipment is one of the most widely used methods for applying coatings to various surfaces. This equipment operates by atomizing the coating material into fine droplets, which are then sprayed onto the surface of the substrate. The process is versatile, allowing for the application of a wide range of coating materials, including paints, varnishes, and adhesives.

The versatility of spray coating makes it ideal for a variety of industries, including automotive, aerospace, and consumer goods. In the automotive sector, for example, spray coating is used to apply paint finishes to vehicles, providing not only aesthetic appeal but also protection against corrosion and wear. The aerospace industry also relies heavily on spray coating to protect aircraft components from environmental factors such as UV radiation and extreme temperatures.

One of the key advantages of spray coating is its ability to achieve a smooth, uniform finish, even on complex geometries. This is particularly important in industries where the appearance and performance of the coated product are critical. Additionally, advancements in spray coating technology have led to the development of equipment that can apply coatings with minimal overspray, reducing material waste and improving efficiency.

Modern Spray Coating Equipment is also increasingly integrated with automated systems, allowing for precise control over the coating process. Automation ensures that the correct amount of coating is applied consistently across all parts, reducing the likelihood of defects and improving overall product quality. Furthermore, automated spray coating systems can be programmed to handle different coating materials and application techniques, providing manufacturers with the flexibility to meet varying production requirements.

Electrostatic Coating Equipment

Electrostatic Coating Equipment represents another critical technology within the coating equipment industry. This equipment operates by charging the coating particles with an electric charge before they are sprayed onto the substrate. The substrate is grounded, creating an electrostatic attraction that causes the charged particles to adhere to the surface. This method is highly efficient, as it ensures that the coating material is evenly distributed across the surface with minimal waste.

The primary advantage of electrostatic coating is its ability to achieve a high-quality, uniform finish with excellent adhesion. This makes it particularly well-suited for applications where durability and appearance are paramount, such as in the automotive and furniture industries. Electrostatic coating is commonly used to apply paint, powder coatings, and other materials to metal surfaces, providing a durable and attractive finish that can withstand harsh environmental conditions.

Electrostatic coating also offers several environmental benefits. Since the process results in minimal overspray, it reduces the amount of waste material and the need for extensive cleanup. Additionally, the process is highly efficient, meaning that less coating material is required to achieve the desired coverage, further reducing the environmental impact. The reduced need for solvents in electrostatic powder coating also contributes to lower VOC emissions, making it an environmentally friendly option for manufacturers.

In recent years, advancements in Electrostatic Coating Equipment have focused on improving the precision and control of the coating process. Modern equipment is capable of adjusting the voltage and spray pattern in real-time, allowing for greater flexibility in coating application. This is particularly important in industries where different parts require different levels of coating thickness or where complex geometries make uniform coverage challenging.

For manufacturers looking to implement electrostatic coating, it is essential to consider the specific requirements of their production processes. Factors such as the type of coating material, the substrate, and the desired finish will all influence the choice of equipment and settings. Investing in high-quality electrostatic coating equipment can lead to significant improvements in product quality, production efficiency, and environmental sustainability.

Powder Coating Systems

Powder Coating Systems represent a significant segment of the coating equipment industry, offering a durable and environmentally friendly alternative to traditional liquid coatings. Powder coating involves the application of a dry powder, typically composed of finely ground particles of pigment and resin, to a substrate. The coated substrate is then cured under heat, causing the powder to melt and form a hard, continuous coating.

One of the primary advantages of powder coating is its durability. Powder coatings are resistant to chipping, scratching, and fading, making them ideal for products that are exposed to harsh environmental conditions or heavy use. This durability, combined with the ability to achieve a smooth, high-quality finish, has made powder coating the preferred choice for many manufacturers in the automotive, furniture, and appliance industries.

Powder coating is also an environmentally friendly process. Unlike liquid coatings, which often require solvents that emit VOCs, powder coating is a solvent-free process. This means that there are no harmful emissions during application, making it a safer option for both workers and the environment. Additionally, any overspray from the powder coating process can be collected and reused, further reducing waste and improving cost efficiency.

Several types of powder coating systems are available, each designed to meet the specific needs of different industries and applications. Propane Powder Coating Ovens and Gas Curing Ovens are commonly used to cure the powder coating, ensuring that it adheres properly to the substrate and forms a durable finish. Industrial Burn Off Ovens are also used in the powder coating process to remove old coatings from parts, preparing them for a fresh coat.

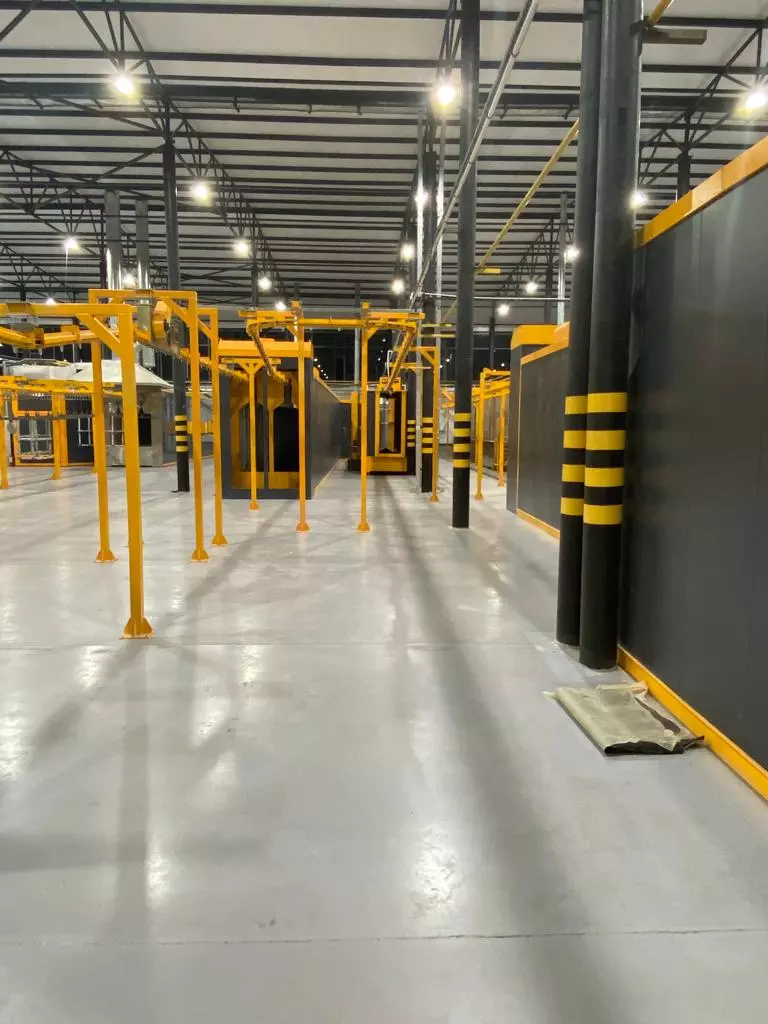

For manufacturers dealing with large or heavy parts, specialized equipment such as Powder Coat Big Parts and Powder Coat Large Parts systems are available. These systems are designed to handle the unique challenges of coating oversized parts, including the need for larger ovens and more powerful spraying systems. Powder Coating Conveyor Plants are also commonly used in high-volume production environments, where parts are continuously coated and cured as they move through the production line.

Powder Coating Wash Systems are another critical component of the powder coating process. These systems are used to clean and prepare parts before coating, ensuring that the surface is free of contaminants that could affect the quality of the finish. Proper pre-treatment is essential for achieving a durable and high-quality powder coat, and modern wash systems are designed to provide consistent and thorough cleaning with minimal water and chemical usage.

In conclusion, the diversity of coating equipment available today reflects the wide range of applications and industries that rely on coating technologies. Whether it’s the versatility of Spray Coating Equipment, the precision of Electrostatic Coating Equipment, or the durability and environmental benefits of Powder Coating Systems, manufacturers have access to a broad spectrum of tools designed to meet their specific needs. As technology continues to advance, we can expect further innovations in coating equipment, driving improvements in efficiency, quality, and sustainability across the industry.

Machinery for Glass Coating

The glass coating industry has experienced significant advancements over the years, driven by the need for enhanced durability, aesthetics, and functionality in glass products. From architectural glass used in buildings to glass bottles and containers, coating technology plays a critical role in improving the performance and extending the lifespan of these materials. In this section, we will explore various types of machinery used in glass coating, including Glass Coating Machinery, Glass Bottle Coating Machinery, and Glass Line Technology.

Glass Coating Machinery

Glass Coating Machinery is designed to apply protective and decorative coatings to glass surfaces. These coatings serve multiple purposes, such as improving scratch resistance, enhancing UV protection, and providing anti-reflective properties. The machinery used for glass coating is highly specialized, capable of handling large sheets of glass or intricate shapes with precision and consistency.

One of the primary applications of glass coating machinery is in the production of architectural glass. In modern construction, there is a growing demand for glass that not only offers aesthetic appeal but also meets stringent performance standards. Coated glass is often used in windows, facades, and skylights to reduce glare, control solar heat gain, and improve energy efficiency. Glass Coating Machinery used in this sector must be capable of applying uniform coatings across large surfaces, ensuring that the glass performs as expected in various environmental conditions.

The technology behind glass coating machinery has evolved to meet the diverse needs of the industry. For example, magnetron sputtering is a common technique used in glass coating, where a thin layer of material is deposited onto the glass surface under a vacuum. This process allows for the precise control of the coating’s thickness and composition, resulting in high-performance glass with properties such as low-emissivity (low-E) and solar control.

Another key area where Glass Coating Machinery is utilized is in the automotive industry. Automotive glass, including windshields, side windows, and rear windows, requires coatings that enhance visibility, reduce glare, and protect against UV radiation. The machinery used in this context must be capable of handling curved and complex shapes, applying coatings that adhere uniformly to the glass surface.

The demand for coated glass is also rising in the electronics industry, particularly for devices such as smartphones, tablets, and monitors. Anti-reflective and anti-glare coatings are applied to the glass screens of these devices to improve visibility and user experience. The precision required in this application is high, and Glass Coating Machinery used in this sector must be able to apply ultra-thin coatings without compromising the clarity or functionality of the glass.

Glass Bottle Coating Machinery

Glass Bottle Coating Machinery is a specialized subset of glass coating equipment designed specifically for the coating of glass bottles and containers. The coatings applied to glass bottles serve multiple purposes, including improving durability, enhancing visual appeal, and providing protection against chemical reactions with the contents of the bottle.

One of the most common applications of Glass Bottle Coating Machinery is in the beverage industry, where bottles are often coated to enhance their appearance and protect the contents from UV light. UV coatings prevent light from penetrating the glass and degrading the quality of the beverage, particularly in the case of beer, wine, and spirits. The machinery used for this purpose must be able to apply coatings uniformly to curved surfaces, ensuring that the entire bottle is adequately protected.

Another important application of Glass Bottle Coating Machinery is in the pharmaceutical industry. Glass bottles used for storing medicines and other sensitive products are often coated to prevent chemical reactions between the glass and the contents. These coatings can also provide additional protection against breakage and contamination. The machinery used in this context must be capable of applying coatings that meet strict industry standards for safety and performance.

In the cosmetics industry, glass bottles and containers are often coated to enhance their visual appeal, creating a premium look and feel for the product. This can include decorative coatings, such as metallic finishes or frosted glass effects, as well as protective coatings that prevent scratches and wear. Glass Bottle Coating Machinery used in this industry must be versatile, allowing for the application of a wide range of coatings to achieve the desired aesthetic and functional properties.

The technology behind Glass Bottle Coating Machinery continues to advance, with innovations aimed at improving efficiency, reducing waste, and enhancing the quality of the coatings applied. For example, automated coating systems are increasingly being used to apply coatings with greater precision and consistency, reducing the likelihood of defects and improving overall production efficiency.

Glass Line Technology

Glass Line Technology refers to the integrated systems and machinery used in the production and coating of glass products. This technology encompasses a wide range of equipment, including cutting, washing, coating, and curing machinery, all of which work together to produce high-quality coated glass products.

In a modern glass production line, Glass Line Technology is essential for ensuring that each stage of the process is optimized for efficiency and quality. For example, before coating, the glass must be thoroughly cleaned to remove any contaminants that could affect the adhesion and performance of the coating. Pre-treatment Nozzles are often used in this stage to apply cleaning solutions or to rinse the glass with water, ensuring that it is free of dust, oils, and other impurities.

Once the glass is cleaned, it moves on to the coating stage, where Glass Coating Machinery applies the desired coating. This stage is critical, as the quality and uniformity of the coating will directly impact the performance and appearance of the final product. Glass Line Technology ensures that the coating is applied with precision, using advanced techniques such as magnetron sputtering or chemical vapor deposition (CVD) to achieve the desired properties.

After coating, the glass must be cured to ensure that the coating adheres properly and achieves the required hardness. This is typically done using Gas Curing Ovens or other specialized curing equipment, which heat the glass to a specific temperature for a set period. Glass Line Technology plays a crucial role in controlling the curing process, ensuring that the glass is heated evenly and cooled at the appropriate rate to prevent thermal stress and defects.

In addition to the core coating and curing processes, Glass Line Technology also includes inspection and quality control systems. These systems use advanced imaging and sensing technologies to detect any defects or inconsistencies in the coated glass, allowing for real-time adjustments to be made to the production process. This ensures that only high-quality glass products reach the final stage of production.

The integration of Glass Line Technology with automation and Industry 4.0 technologies is also becoming increasingly common. Automated production lines can operate with minimal human intervention, reducing the likelihood of errors and increasing overall efficiency. Additionally, smart sensors and data analytics are being used to monitor the performance of the production line in real-time, allowing for predictive maintenance and continuous improvement.

In conclusion, Glass Coating Machinery, Glass Bottle Coating Machinery, and Glass Line Technology are essential components of the glass coating industry, each playing a critical role in producing high-quality coated glass products. Whether it’s for architectural applications, automotive glass, or glass bottles and containers, these technologies ensure that glass products meet the highest standards of durability, aesthetics, and performance. As the industry continues to evolve, we can expect further advancements in glass coating machinery and technology, driving improvements in efficiency, quality, and sustainability.

Powder Coating Systems and Equipment

Powder coating has become a cornerstone of modern manufacturing, offering a durable, efficient, and environmentally friendly alternative to traditional liquid coatings. The powder coating process involves applying a dry powder to a substrate, which is then cured under heat to form a hard, continuous coating. This section explores the various components of powder coating systems, including Powder Coating Ovens, Powder Coating Wash Systems, Conveyor Systems, and specialized equipment for coating large parts.

Powder Coating Ovens

Powder Coating Ovens are essential for curing the applied powder, transforming it from a dry, powdery substance into a hard, smooth finish. These ovens are designed to provide the precise temperature control necessary for the powder to flow and form a uniform, durable coating. The curing process is critical in determining the final properties of the coating, such as its adhesion, hardness, and resistance to environmental factors.

There are several types of powder coating ovens, each suited to different applications and production environments:

- Propane Powder Coating Oven: These ovens use propane as a fuel source, offering an efficient and cost-effective solution for curing powder coatings. Propane ovens are particularly popular in industries where natural gas may not be readily available or where portability is essential. They provide consistent heat distribution, ensuring that the powder coating cures evenly across the entire surface of the substrate.

- Gas Curing Ovens: Similar to propane ovens, Gas Curing Ovens use natural gas or propane to generate the heat needed for curing. These ovens are known for their efficiency and ability to maintain stable temperatures, making them ideal for high-volume production environments. The even heat distribution provided by gas curing ovens ensures that the coating cures uniformly, resulting in a high-quality finish.

- Industrial Burn Off Ovens: These specialized ovens are used to remove old coatings from parts before they are recoated. Industrial Burn Off Ovens use high temperatures to break down and remove existing coatings, preparing the surface for a new powder coating application. This process is essential in industries where parts need to be refurbished or where old coatings need to be stripped before applying a new layer.

Each type of Powder Coating Oven is designed to meet specific industry needs, with features such as precise temperature control, efficient heat distribution, and robust construction to withstand the demands of industrial environments. The choice of oven will depend on factors such as the type of powder being used, the size and shape of the parts, and the production volume.

Powder Coating Wash Systems

Before the powder coating process can begin, the parts must be thoroughly cleaned and prepared to ensure proper adhesion of the coating. Powder Coating Wash Systems are designed to remove contaminants such as oils, dirt, and rust from the surface of the parts, creating a clean substrate that allows the powder to adhere effectively.

Powder Coating Wash Systems typically involve a multi-stage process, which may include the following steps:

- Pre-treatment Nozzles: These nozzles are used to apply cleaning solutions or rinses to the parts, ensuring that all contaminants are removed. The pre-treatment stage is crucial for achieving a high-quality finish, as any remaining contaminants can lead to defects in the coating.

- Rinse Stages: After the cleaning solutions are applied, the parts are rinsed with water to remove any residual chemicals. This step is essential for preventing contamination and ensuring that the parts are ready for coating.

- Drying Stages: Once the parts have been cleaned and rinsed, they are dried using heat or air to remove any moisture. This step ensures that the parts are completely dry before the powder is applied, which is critical for achieving a smooth, even finish.

Modern Powder Coating Wash Systems are designed to be efficient and environmentally friendly, using minimal water and chemicals while ensuring thorough cleaning. These systems are essential for industries where high-quality finishes are required, as they help prevent defects and ensure that the powder coating adheres properly.

Conveyor Systems for Powder Coating

In high-volume production environments, conveyor systems are used to move parts through the various stages of the powder coating process. These systems are designed to streamline production, ensuring that parts are coated, cured, and finished efficiently and consistently. Conveyor Systems for Powder Coating can vary widely in design, depending on the specific needs of the production line.

- Power & Free Coating Line: This type of conveyor system offers flexibility in the coating process, allowing parts to be held in place or moved along the line as needed. Power & Free Coating Lines are ideal for complex production environments where parts may need to be held in place for additional coating or curing time. The system allows for precise control over the movement of parts, ensuring that each part receives the appropriate amount of coating and curing time.

- Powder Coating Conveyor Plant: These conveyor systems are designed for large-scale powder coating operations, where high volumes of parts need to be coated quickly and efficiently. Powder Coating Conveyor Plants are typically integrated with other systems, such as ovens and wash systems, to create a seamless production line. The continuous movement of parts through the line ensures that production is efficient, with minimal downtime and consistent quality.

- Conveyor Painting System: While primarily associated with liquid coatings, Conveyor Painting Systems can also be adapted for use with powder coatings. These systems are designed to move parts through the coating and curing stages in a controlled and efficient manner, ensuring that each part receives a uniform coating. The integration of conveyor systems into the powder coating process helps to increase productivity and reduce labor costs.

Powder Coating for Large Parts

Powder coating large or heavy parts presents unique challenges, requiring specialized equipment and systems designed to handle the size and weight of the parts. Powder Coat Big Parts and Powder Coat Large Parts systems are specifically engineered to address these challenges, ensuring that even the largest parts receive a high-quality powder coating.

Coating large parts, such as industrial machinery, structural components, or automotive parts, requires ovens and spraying systems that can accommodate the size of the parts while providing even coverage. Powder Coating Ovens used for large parts must be large enough to fit the parts comfortably while maintaining consistent temperatures throughout the curing process. This ensures that the powder coating cures uniformly, resulting in a durable and attractive finish.

Specialized spraying systems are also required to apply powder coatings to large parts. These systems must be capable of delivering a consistent powder flow and coverage across the entire surface of the part, even in hard-to-reach areas. Powder Coating Wash Systems designed for large parts must be robust enough to handle the size and weight of the parts while ensuring thorough cleaning and preparation.

In industries such as automotive, aerospace, and construction, where large parts are commonly used, the ability to powder coat large parts efficiently and effectively is critical. The equipment and systems designed for this purpose play a vital role in ensuring that these parts meet the required standards for durability, performance, and appearance.

Automatism and Pre-treatment in Coating

In the modern coating industry, automation and pre-treatment processes play a crucial role in ensuring that coatings are applied efficiently, consistently, and with high quality. Automation reduces the need for manual intervention, leading to more precise control over the coating process, while pre-treatment is essential for preparing surfaces to receive coatings, ensuring proper adhesion and durability. This section explores the importance of Automatism for Coating and Finishing Panels and the role of Pre-treatment Nozzles in the coating process.

Automatism for Coating and Finishing Panels

The adoption of automation in the coating industry, referred to as Automatism for Coating and Finishing Panels, has revolutionized the way coatings are applied across various sectors. Automation involves the use of advanced machinery and control systems to handle different stages of the coating process, from surface preparation to the final finish. This technology is increasingly being integrated into production lines to enhance efficiency, improve product quality, and reduce operational costs.

One of the key benefits of Automatism for Coating and Finishing Panels is its ability to provide consistent and precise control over the coating process. Automated systems can be programmed to apply coatings with exact thicknesses, ensuring uniformity across all parts. This level of control is particularly important in industries where the quality of the coating has a direct impact on the performance and durability of the final product, such as in the automotive, aerospace, and electronics sectors.

Automation also reduces the likelihood of human error, which can lead to defects in the coating. By minimizing manual intervention, automated systems ensure that each part is coated to the same standard, reducing the need for rework and improving overall production efficiency. Additionally, automated systems can operate continuously, increasing throughput and allowing manufacturers to meet high production demands without compromising on quality.

In the context of Coating and Finishing Panels, automation allows for the seamless integration of different processes, such as spraying, curing, and inspection, into a single production line. This integration streamlines the workflow, reduces production time, and ensures that each stage of the coating process is optimized for efficiency and quality. For example, automated spraying systems can adjust the spray pattern and flow rate in real-time, based on the size and shape of the panels being coated, ensuring complete coverage with minimal overspray.

Another advantage of Automatism for Coating and Finishing Panels is its ability to handle complex geometries and large parts with ease. Automated systems can be equipped with multi-axis robots that can move around the parts, applying coatings evenly to all surfaces, including those that are difficult to reach with manual methods. This capability is particularly valuable in industries such as automotive manufacturing, where large panels with intricate shapes are common.

Moreover, automation enables the use of advanced coating technologies, such as electrostatic and powder coating, which require precise control over the application process to achieve the desired finish. By integrating these technologies into an automated production line, manufacturers can achieve higher levels of efficiency and quality, while also reducing waste and environmental impact.

The trend towards greater automation in the coating industry is also being driven by the need for increased flexibility and customization. Modern automated systems are designed to be highly adaptable, allowing manufacturers to quickly changeover between different products or coatings with minimal downtime. This flexibility is essential in today’s market, where there is a growing demand for customized products and shorter production runs.

In summary, Automatism for Coating and Finishing Panels represents a significant advancement in the coating industry, offering manufacturers the ability to apply coatings with greater precision, consistency, and efficiency. By reducing the need for manual intervention and integrating advanced technologies, automation is helping to drive improvements in product quality, production efficiency, and environmental sustainability.

Pre-treatment Nozzles

Pre-treatment is a critical step in the coating process, as it prepares the surface of the parts to receive the coating. Without proper pre-treatment, coatings may not adhere properly, leading to defects such as peeling, blistering, or poor corrosion resistance. Pre-treatment Nozzles play a vital role in this process, ensuring that the surface is thoroughly cleaned and prepared before the coating is applied.

Pre-treatment Nozzles are used to apply cleaning solutions, water, or other chemicals to the surface of the parts, removing contaminants such as oils, dirt, rust, and other residues that could interfere with the coating process. The effectiveness of the pre-treatment process depends on the design and performance of the nozzles, which must deliver the cleaning agents with the right pressure, coverage, and flow rate to achieve the desired results.

One of the most common applications of Pre-treatment Nozzles is in the cleaning and rinsing stages of the pre-treatment process. During the cleaning stage, nozzles are used to apply degreasers or other cleaning solutions to the surface of the parts, breaking down and removing oils, grease, and other contaminants. This step is essential for ensuring that the surface is clean and free of any substances that could prevent the coating from adhering properly.

After the cleaning solution has been applied, the parts are typically rinsed with water to remove any residual chemicals. Pre-treatment Nozzles used in the rinsing stage must provide even coverage across the entire surface of the parts, ensuring that all traces of the cleaning solution are removed. This is important for preventing contamination and ensuring that the parts are ready for coating.

In addition to cleaning and rinsing, Pre-treatment Nozzles can also be used to apply conversion coatings, which are often used to improve the adhesion and corrosion resistance of the final coating. Conversion coatings, such as phosphate or chromate coatings, are applied using nozzles that deliver the coating solution with precise control over the flow rate and coverage. This ensures that the conversion coating is applied evenly and with the correct thickness, providing the necessary surface properties for the final coating.

The design of Pre-treatment Nozzles is critical to their performance. Factors such as spray pattern, flow rate, and pressure must be carefully controlled to ensure that the nozzles deliver the cleaning or coating solution effectively. For example, fan-shaped nozzles are often used for wide coverage, while cone-shaped nozzles are used for more concentrated application. The choice of nozzle will depend on the specific requirements of the pre-treatment process and the type of parts being coated.

Modern Pre-treatment Nozzles are also designed to be energy-efficient and environmentally friendly. They are engineered to use minimal amounts of water and chemicals while still achieving thorough cleaning and preparation. This not only reduces the environmental impact of the pre-treatment process but also helps manufacturers to reduce operating costs by conserving resources.

In conclusion, Pre-treatment Nozzles are an essential component of the coating process, playing a critical role in ensuring that parts are properly prepared before coating. By providing precise and efficient application of cleaning agents, rinsing water, and conversion coatings, these nozzles help to ensure that the final coating adheres properly and performs as expected. As the coating industry continues to evolve, the development of advanced pre-treatment technologies, including high-performance nozzles, will remain a key focus for manufacturers seeking to improve quality, efficiency, and sustainability.

Specialized Coating Equipment

The coating industry is incredibly diverse, with different sectors requiring specific technologies and machinery tailored to their unique needs. This section will delve into the specialized coating equipment that serves niche markets, such as Calcium Carbonate Coating Machine Suppliers, 3″ Oven Wheels, Gas/Oil Curing Ovens, and Oven Powder Coating Systems. These specialized pieces of equipment play crucial roles in their respective industries, ensuring that coatings meet high standards for quality, durability, and performance.

Calcium Carbonate Coating Machine Suppliers

Calcium Carbonate Coating Machines are specialized equipment used in the processing of calcium carbonate, a widely used material in various industries, including plastics, paints, paper, and construction. Calcium carbonate is often used as a filler material, providing volume and improving the properties of the final product. However, to enhance its performance, the calcium carbonate particles are often coated with stearic acid or other fatty acids to improve dispersion and compatibility with other materials.

Calcium Carbonate Coating Machine Suppliers provide machinery designed to apply these coatings uniformly to calcium carbonate particles. The coating process typically involves mixing the calcium carbonate with the coating agent in a high-shear environment, ensuring that each particle is thoroughly coated. This improves the material’s performance in applications such as plastics manufacturing, where coated calcium carbonate can improve the mechanical properties of the final product and reduce production costs.

The equipment provided by Calcium Carbonate Coating Machine Suppliers is designed to handle the specific challenges associated with coating fine particles. These machines must be able to operate at high speeds while maintaining precise control over the coating process. Additionally, they must be robust enough to handle abrasive materials and ensure consistent, high-quality output.

Key features of these machines include advanced mixing technologies, precise temperature and pressure controls, and efficient energy usage. By optimizing these parameters, the coating machines ensure that the calcium carbonate is coated evenly, enhancing its performance and making it suitable for high-quality applications.

3″ Oven Wheel

The 3″ Oven Wheel is a critical component in industrial ovens, particularly those used in powder coating and other high-temperature processes. These wheels are designed to withstand the intense heat of curing ovens while providing smooth and reliable movement for parts as they travel through the oven on conveyor systems. The quality and durability of 3″ Oven Wheels are crucial for maintaining the efficiency and consistency of the coating process.

3″ Oven Wheels are typically made from high-temperature-resistant materials, such as steel or specialized polymers, that can endure prolonged exposure to the heat generated in curing ovens. The design of these wheels ensures that they can carry the weight of large or heavy parts without deforming or failing, which is essential for preventing disruptions in the production line.

In a powder coating system, the 3″ Oven Wheel plays a significant role in ensuring that parts move through the oven at a consistent speed, which is critical for achieving a uniform cure. Any variation in speed or movement can lead to uneven curing, resulting in defects such as bubbling, orange peel, or incomplete curing. By providing stable and reliable movement, 3″ Oven Wheels help ensure that the coating cures evenly and adheres properly to the substrate.

These wheels must also be designed to resist wear and tear over time, as they are subjected to continuous use in high-temperature environments. This durability is essential for minimizing maintenance and replacement costs, ensuring that the coating system operates efficiently with minimal downtime.

Gas/Oil Curing Ovens

Gas/Oil Curing Ovens are essential equipment in the coating industry, particularly for curing powder coatings and other high-performance finishes. These ovens use either natural gas or oil as a fuel source to generate the heat needed to cure coatings, transforming them from a powder or liquid state into a hard, durable finish. The choice of fuel depends on factors such as cost, availability, and environmental considerations.

Gas/Oil Curing Ovens are widely used in industries where high throughput and consistent quality are required. These ovens are designed to maintain precise temperature control, ensuring that the coating cures uniformly across all parts. The even heat distribution provided by these ovens is critical for achieving a high-quality finish, as any variation in temperature can lead to defects in the coating, such as blisters, bubbles, or incomplete curing.

One of the key advantages of Gas/Oil Curing Ovens is their ability to heat up quickly and maintain stable temperatures throughout the curing process. This is particularly important in high-volume production environments, where any delay or inconsistency in the curing process can lead to significant production losses. The rapid heating capabilities of these ovens also contribute to energy efficiency, reducing operating costs while maintaining high production rates.

In addition to their performance benefits, Gas/Oil Curing Ovens are also designed with safety and environmental considerations in mind. These ovens are equipped with advanced controls and monitoring systems that ensure safe operation, including features such as automatic shutoff in the event of a malfunction or temperature fluctuation. Furthermore, modern ovens are designed to minimize emissions and reduce fuel consumption, making them a more environmentally friendly option for manufacturers.

Oven Powder Coating System

The Oven Powder Coating System is a comprehensive setup that integrates all the necessary components for the powder coating process, from pre-treatment and powder application to curing and finishing. These systems are designed to provide manufacturers with a turnkey solution for applying powder coatings to a wide range of parts, ensuring that the entire process is efficient, consistent, and high-quality.

An Oven Powder Coating System typically includes several key components:

- Pre-treatment Systems: These systems clean and prepare the parts before coating, removing contaminants that could affect the adhesion and quality of the final coating. Pre-treatment is critical for ensuring that the coating adheres properly and provides the desired level of protection and durability.

- Powder Application Booths: In these booths, the powder coating is applied to the parts using electrostatic spray guns or other application methods. The design of the booth ensures that the powder is applied evenly and with minimal waste, while also providing a controlled environment to prevent contamination.

- Curing Ovens: The curing oven is the heart of the Oven Powder Coating System. This oven heats the coated parts to the required temperature, causing the powder to melt and form a continuous, durable finish. The design of the curing oven is critical for ensuring that the coating cures evenly and consistently, without defects.

- Conveyor Systems: These systems transport the parts through each stage of the powder coating process, from pre-treatment and powder application to curing and cooling. The conveyor system must be carefully designed to ensure that the parts move through the process at the correct speed and with minimal handling, reducing the risk of damage or defects.

- Cooling Systems: After curing, the parts must be cooled to allow the coating to harden fully and achieve its final properties. Cooling systems are typically integrated into the Oven Powder Coating System to provide a controlled environment for the parts to cool gradually, preventing thermal shock and ensuring that the coating maintains its integrity.

The Oven Powder Coating System is designed to provide a complete solution for manufacturers, enabling them to apply high-quality powder coatings with maximum efficiency and minimal waste. These systems are used across various industries, including automotive, aerospace, construction, and consumer goods, where high-performance finishes are required.

In summary, specialized coating equipment such as Calcium Carbonate Coating Machines, 3″ Oven Wheels, Gas/Oil Curing Ovens, and Oven Powder Coating Systems play critical roles in the coating industry. Each piece of equipment is designed to meet the specific needs of its respective application, ensuring that coatings are applied efficiently, consistently, and with the highest levels of quality. As the industry continues to evolve, the development of advanced and specialized coating equipment will remain a key focus for manufacturers seeking to improve their processes and products.

Designing Efficient Coating Plant Layouts

The design of a coating plant layout is critical to the overall efficiency, productivity, and quality of the coating process. A well-planned layout ensures that all stages of the coating process—from pre-treatment to curing—are seamlessly integrated, minimizing downtime, reducing waste, and maximizing throughput. This section explores the key considerations in designing a Powder Coating Plant Layout and Coating Line Design, focusing on optimizing workflow, ensuring safety, and accommodating future growth.

Powder Coating Plant Layout

The Powder Coating Plant Layout is the blueprint for how the entire powder coating process is organized within a manufacturing facility. This layout must be carefully designed to ensure that the various stages of the process—pre-treatment, powder application, curing, and cooling—are arranged in a logical and efficient sequence. A well-designed layout minimizes the distance that parts must travel between stages, reducing handling time and the risk of damage or contamination.

One of the first considerations in designing a Powder Coating Plant Layout is the size and shape of the parts that will be coated. The layout must be flexible enough to accommodate parts of different sizes and shapes, ensuring that the equipment can handle a wide range of products without requiring significant adjustments or reconfigurations. For example, if the plant will be coating large parts, the layout must include ample space for oversized ovens, spray booths, and conveyor systems.

Another key consideration is the flow of materials through the plant. The layout should be designed to facilitate a smooth and continuous flow of parts from one stage of the process to the next. This involves carefully planning the placement of equipment, such as Powder Coating Ovens, Conveyor Systems, and Powder Coating Wash Systems, to ensure that there are no bottlenecks or delays in the production line. The goal is to create a linear and logical workflow that minimizes the time and effort required to move parts through the plant.

In addition to the flow of materials, the layout must also consider the flow of workers. The design should ensure that workers can easily access all areas of the plant, including maintenance and inspection points, without disrupting the production process. Clear pathways and workstations should be incorporated into the layout to facilitate safe and efficient movement throughout the facility.

Safety is another critical factor in designing a Powder Coating Plant Layout. The layout must comply with all relevant safety regulations and standards, ensuring that workers are protected from potential hazards, such as exposure to chemicals, heat, and moving machinery. This includes incorporating safety features such as ventilation systems, fire suppression systems, and emergency exits. Additionally, the layout should allow for easy access to safety equipment and first aid stations, ensuring that workers can quickly respond to any emergencies.

Environmental considerations are also important when designing a Powder Coating Plant Layout. The layout should be designed to minimize energy consumption and waste generation, contributing to the overall sustainability of the operation. This can include the use of energy-efficient Gas/Oil Curing Ovens, recycling systems for powder overspray, and water-saving features in pre-treatment systems. By incorporating these elements into the layout, manufacturers can reduce their environmental impact while also lowering operating costs.

Finally, the layout must be designed with future growth in mind. As the business expands or as new technologies are introduced, the plant layout should be able to accommodate additional equipment, increased production volumes, and new processes without requiring a complete overhaul. This can be achieved by leaving space for expansion, using modular equipment that can be easily reconfigured, and incorporating flexible utility connections that can be adapted to new requirements.

Coating Line Design

Coating Line Design is a subset of plant layout design that focuses specifically on the arrangement and configuration of the equipment used in the coating process. The goal of coating line design is to create an efficient, reliable, and high-quality coating process that meets the specific needs of the product being coated.

One of the primary considerations in Coating Line Design is the choice of coating method. Depending on the product and the desired finish, different coating methods may be used, such as spray coating, electrostatic coating, or powder coating. The design of the coating line must accommodate the specific requirements of the chosen method, including the type of equipment, the flow of materials, and the curing process.

For example, in a Powder Coating Conveyor Plant, the design of the conveyor system is critical to the overall efficiency of the coating process. The conveyor must be capable of moving parts through the various stages of the process at the correct speed, ensuring that each part receives the appropriate amount of coating and curing time. The design of the conveyor system must also consider the size and weight of the parts, ensuring that the system can handle the load without causing delays or damage.

The placement of Coating Equipment is another important consideration in Coating Line Design. The equipment must be arranged in a way that allows for easy access for maintenance and inspection while also ensuring that the process flow is uninterrupted. For example, spray booths should be placed near the pre-treatment area to minimize the time between cleaning and coating, while curing ovens should be located immediately after the application stage to ensure that the powder is cured quickly and evenly.

The integration of automation is also a key factor in Coating Line Design. Automated systems, such as Automatism for Coating and Finishing Panels, can significantly improve the efficiency and consistency of the coating process. These systems can be programmed to apply coatings with precise control over thickness, coverage, and curing time, reducing the likelihood of defects and improving overall product quality. The design of the coating line must allow for the integration of these automated systems, ensuring that they can operate seamlessly with the other equipment.

Quality control is another important aspect of Coating Line Design. The coating line should include inspection points where parts can be checked for defects before moving on to the next stage of the process. This can include visual inspections, thickness measurements, and adhesion tests. By incorporating these quality control measures into the design, manufacturers can ensure that any issues are identified and addressed early in the process, reducing the likelihood of costly rework or product recalls.

Finally, Coating Line Design must also consider the environmental impact of the coating process. This includes the use of energy-efficient equipment, such as Gas/Oil Curing Ovens, and the implementation of waste-reduction measures, such as recycling systems for powder overspray. By designing the coating line with sustainability in mind, manufacturers can reduce their environmental footprint while also improving the efficiency and cost-effectiveness of their operations.

Conclusion and Future Trends

The coating equipment industry has undergone significant advancements over the years, driven by the need for improved efficiency, quality, and sustainability in manufacturing processes. From Spray Coating Equipment and Powder Coating Ovens to specialized machinery like Glass Coating Machinery and Calcium Carbonate Coating Machines, the industry offers a diverse range of technologies tailored to meet the specific needs of various sectors. As we look to the future, several key trends are expected to shape the evolution of the coating equipment industry, driving further innovation and growth.

The Role of Automation and Industry 4.0

Automation has already transformed the coating industry, and its impact is set to increase as manufacturers continue to adopt Industry 4.0 technologies. Automatism for Coating and Finishing Panels and other automated systems enable manufacturers to achieve higher levels of precision, consistency, and efficiency in their coating processes. The integration of smart sensors, real-time data analytics, and machine learning algorithms allows for continuous monitoring and optimization of the coating process, reducing waste, improving product quality, and lowering operating costs.

In the future, we can expect to see more advanced automation systems that are capable of self-adjusting based on real-time data inputs, further enhancing the flexibility and responsiveness of coating lines. These systems will be able to adapt to changes in production demands, materials, and environmental conditions, ensuring optimal performance at all times. The continued development of collaborative robots, or “cobots,” will also play a role in enhancing automation in the coating industry, enabling more seamless integration between human workers and automated systems.

Sustainability and Environmental Considerations

As environmental regulations become increasingly stringent, the coating equipment industry is under pressure to develop more sustainable solutions. The shift towards eco-friendly coatings, such as water-based and low-VOC options, is already well underway. However, the industry is also exploring new ways to reduce the environmental impact of coating processes, including energy-efficient Gas/Oil Curing Ovens, recycling systems for powder overspray, and technologies that minimize water and chemical usage in pre-treatment processes.

Future advancements are likely to focus on further reducing the carbon footprint of coating operations. This could include the development of new coating materials that require less energy to cure, innovations in renewable energy integration for curing ovens, and the continued improvement of waste reduction and recycling technologies. Manufacturers will also likely invest in more comprehensive lifecycle assessments to better understand and minimize the environmental impact of their coating processes from start to finish.

Customization and Flexibility in Coating Equipment

The demand for customized products and shorter production runs is driving the need for more flexible and adaptable coating equipment. Manufacturers are increasingly seeking solutions that allow them to quickly changeover between different products or coatings without significant downtime. This trend is pushing the industry towards the development of modular and reconfigurable coating systems that can be easily adapted to different production requirements.

For example, Powder Coating Conveyor Plants are being designed with greater flexibility in mind, allowing manufacturers to adjust the speed, temperature, and configuration of the line to accommodate different types of parts and coatings. Similarly, advances in Coating Line Design are enabling more efficient and customizable production processes, allowing manufacturers to meet the growing demand for personalized products without sacrificing efficiency or quality.

In the future, we can expect to see even more sophisticated coating systems that offer a high degree of customization, including the ability to switch between different coating methods (e.g., powder, liquid, or electrostatic) with minimal reconfiguration. The integration of digital twins and simulation technologies will also enable manufacturers to test and optimize different coating processes virtually before implementing them on the production line, reducing the risk of errors and improving overall efficiency.

Advancements in Coating Technologies

Technological advancements continue to drive innovation in the coating equipment industry, leading to the development of new coating materials, methods, and equipment. Nanotechnology, for instance, is opening up new possibilities in the realm of advanced coatings, enabling the development of ultra-thin, high-performance coatings with unique properties such as self-cleaning, anti-microbial, and super-hydrophobic surfaces. These coatings are increasingly being used in industries such as electronics, healthcare, and automotive, where they offer significant performance advantages.

Another area of advancement is in the field of additive manufacturing, or 3D printing. As this technology becomes more widespread, there is growing interest in developing specialized coatings for 3D-printed parts, including both functional and decorative finishes. The development of coating equipment that can be seamlessly integrated with 3D printing processes will be a key focus for the industry, enabling manufacturers to produce fully finished parts directly from the printer.

Moreover, the industry is exploring the potential of advanced surface treatment technologies, such as plasma and laser treatments, to enhance the adhesion and performance of coatings. These technologies offer the ability to modify the surface properties of a substrate at a microscopic level, creating ideal conditions for coating adhesion and improving the overall durability and performance of the coated product.

The Future of Coating Equipment Industry

The future of the coating equipment industry is poised to be shaped by a combination of technological innovation, environmental responsibility, and the need for greater flexibility and customization. As manufacturers continue to seek ways to improve the efficiency, quality, and sustainability of their operations, the demand for advanced coating equipment will only grow.

Investment in research and development will be critical in driving the next wave of innovations in the industry. Companies that can develop cutting-edge technologies and solutions that address the evolving needs of manufacturers will be well-positioned to lead the market. Additionally, collaboration between equipment manufacturers, material suppliers, and end-users will play a key role in accelerating the adoption of new technologies and best practices across the industry.

In conclusion, the coating equipment industry is entering an exciting period of transformation, driven by advancements in automation, sustainability, customization, and technology. As the industry continues to evolve, manufacturers will need to stay ahead of the curve by adopting the latest innovations and adapting to the changing demands of the market. By doing so, they can ensure that their coating processes remain efficient, competitive, and environmentally responsible, positioning themselves for long-term success in an increasingly dynamic and challenging global marketplace.

Not only do we manufacture our powder coating equipment, we also ship them worldwide to your facility with care

We’re not just the manufacturers of your powder coating equipment, we’re also your worldwide delivery partners.

At EMS Powder Coating Equipment, we understand that getting your powder coating equipment to you quickly and safely is just as important as manufacturing it to the highest standards. That’s why we offer worldwide delivery services to all of our customers.

We work with a network of experienced and reliable shipping partners to ensure that your equipment arrives on time and in perfect condition. We also offer a variety of shipping options to fit your budget and needs.

Whether you need your equipment shipped to a local address or to an international destination, we can help. We’ll work with you to choose the best shipping option for your needs and to keep you updated on the status of your shipment every step of the way.

So when you choose EMS for your powder coating equipment, you’re not just getting the best products on the market, you’re also getting the best possible delivery experience.

Contact us today to learn more about our worldwide delivery services.