A powder coating machine is a piece of equipment used in the powder coating process, which is a dry finishing process applied as a free-flowing, dry powder. The main components of a powder coating system typically include a spray gun or application device, a powder feeder or hopper, and a curing oven.

Powder Coating Machine

Here’s a breakdown of the key components:

- Powder Gun/Applicator: This is the tool used to apply the powder coating onto the surface of the object. The gun charges the powder particles with an electrostatic charge, and the charged powder adheres to the grounded workpiece.

- Powder Hopper/Feeder: The powder hopper or feeder is a container that holds the dry powder coating material. The powder is typically poured or pumped into the hopper, and it is then transported to the gun through a system of hoses and tubes.

- Control Unit: The control unit manages the settings and parameters of the powder coating process. This includes the electrostatic charge applied to the powder, the air pressure for propelling the powder, and other factors to ensure a consistent and even coating.

- Powder Recovery System: This is a system designed to collect and recycle oversprayed powder. It helps to minimize waste and ensure efficient use of the coating material.

- Curing Oven: After the powder is applied, the coated object is moved into a curing oven. The curing process involves heating the coated object to a specific temperature, allowing the powder to melt, flow, and cure into a durable and attractive finish.

The powder coating process has several advantages, including durability, environmental friendliness (as it does not involve solvents), and the ability to produce a uniform and high-quality finish.

Keep in mind that there are various types of powder coating machines designed for different applications, such as manual or automatic systems, and they may have different features depending on the specific requirements of the coating process.

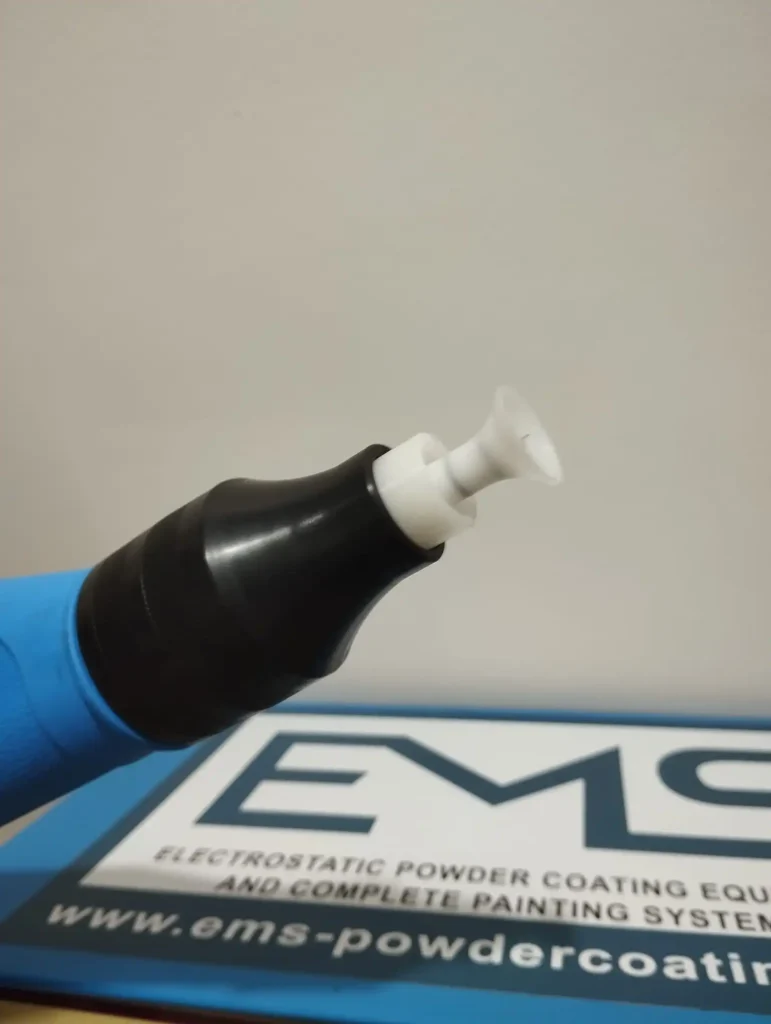

Powder Gun/Applicator – Powder Coating Machine

The powder gun or applicator is a critical component in the powder coating process. It is the tool used to apply the dry powder coating material onto the surface of the object being coated. The primary function of the powder gun is to impart an electrostatic charge to the powder particles, allowing them to adhere to the grounded workpiece.

Here are some key features and aspects of a powder coating gun:

- Electrostatic Charging: The powder gun applies an electrostatic charge to the powder particles as they pass through the gun. This charge is essential for attracting the powder particles to the grounded workpiece, ensuring an even and uniform coating.

- Nozzle and Spray Pattern: The powder gun typically has a nozzle that shapes and directs the spray pattern of the powder. The nozzle design affects the width and intensity of the spray, influencing the coverage and quality of the coating.

- Voltage and Current Controls: The gun’s control unit allows operators to adjust the voltage and current settings, influencing the electrostatic charge applied to the powder. This control is essential for achieving optimal coating results and adapting to different types of workpieces.

- Trigger and Triggering Mechanism: Powder coating guns often have a trigger mechanism that allows the operator to control the application process. Some guns may have additional features like adjustable trigger sensitivity for precise control.

- Powder Flow Control: The rate at which powder is released from the gun is crucial for achieving the desired coating thickness. Powder guns typically have a flow control mechanism that allows operators to adjust the powder feed rate.

- Grounding and Safety: The gun and its components must be properly grounded to ensure the efficient transfer of the electrostatic charge to the powder particles. Proper grounding is essential for safety and for achieving an effective coating.

- Ease of Cleaning and Maintenance: Powder coating guns need to be cleaned regularly to prevent clogs and ensure consistent performance. Many guns are designed for easy disassembly and cleaning to minimize downtime.

Powder coating guns are available in various configurations, including manual and automatic systems. Manual guns are handheld and operated by a person, while automatic guns are often part of a robotic or conveyorized system. The choice of a powder gun depends on the specific requirements of the coating application and the level of automation desired.

Powder Hopper/Feeder of the Powder Coating Machine

The powder hopper or feeder is a crucial component in a powder coating system, serving as the container that holds and supplies the dry powder coating material to the powder gun or applicator. Its primary function is to ensure a continuous and controlled flow of powder during the coating process. Here are the key aspects and features of a powder hopper or feeder:

- Container Design: The hopper is a container designed to hold the dry powder coating material. It can vary in size depending on the specific application and the volume of powder needed for the coating process.

- **Material: **Powder hoppers are commonly made from materials such as stainless steel or other durable materials that resist corrosion and are easy to clean. This is important to prevent contamination of the powder and ensure a consistent coating.

- Powder Fluidization: Some hoppers use a fluidizing system to keep the powder in a fluid-like state. This is achieved by introducing air into the powder, preventing it from clumping and promoting a consistent flow. Fluidization is particularly useful for fine or dense powders.

- Level Sensors: Hoppers may be equipped with sensors to monitor the powder level. These sensors help ensure that an adequate amount of powder is available for the coating process and can signal when the powder needs replenishing.

- Powder Transfer System: The hopper is connected to the powder gun through a system of hoses and tubes. A powder feeder within the hopper controls the flow of powder to the gun. The design of this transfer system is crucial for maintaining a consistent powder feed rate.

- Vibratory Feeders: In some cases, hoppers use vibratory feeders to assist in the controlled release of powder. Vibratory feeders help prevent powder from clumping and ensure a uniform flow to the powder gun.

- Quick-Release Mechanisms: To facilitate color changes or maintenance, some hoppers have quick-release mechanisms that allow for easy removal and cleaning. This is important when switching between different powder colors or formulations.

- Air Filtration: Hoppers may include air filtration systems to remove any airborne contaminants or particles that could affect the quality of the powder coating.

The design and features of powder hoppers can vary based on the specific requirements of the powder coating application, including the type of powder used, the desired coating thickness, and the overall system configuration. Proper maintenance and cleaning of the powder hopper are essential to ensure the quality and consistency of the powder coating process.

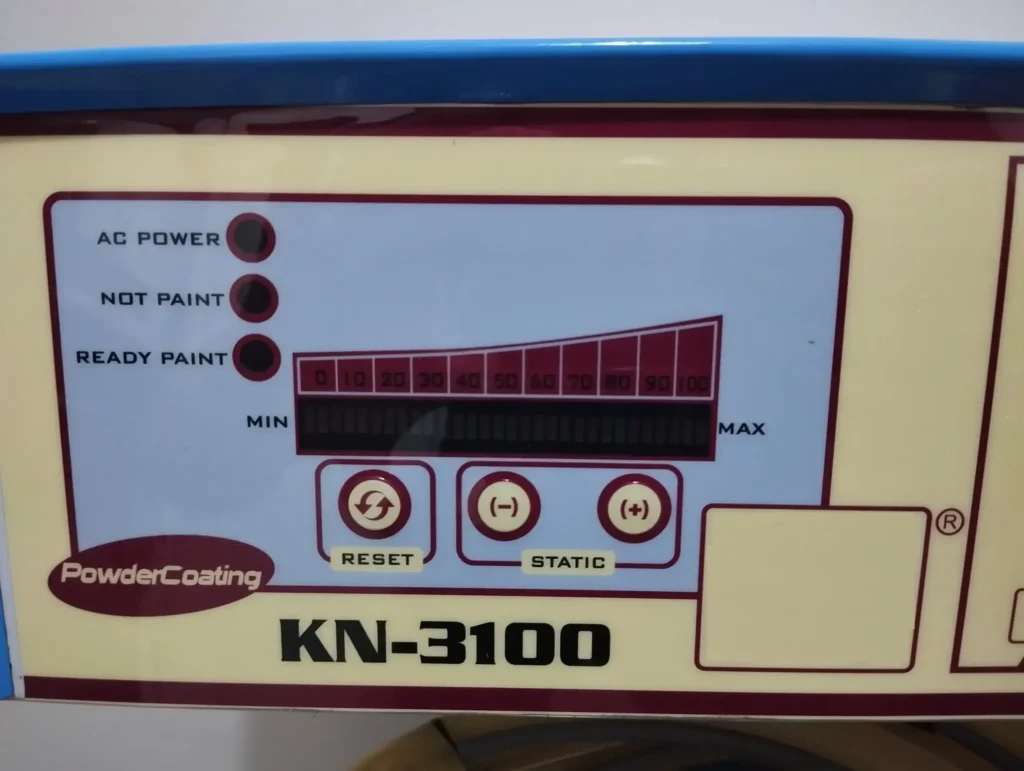

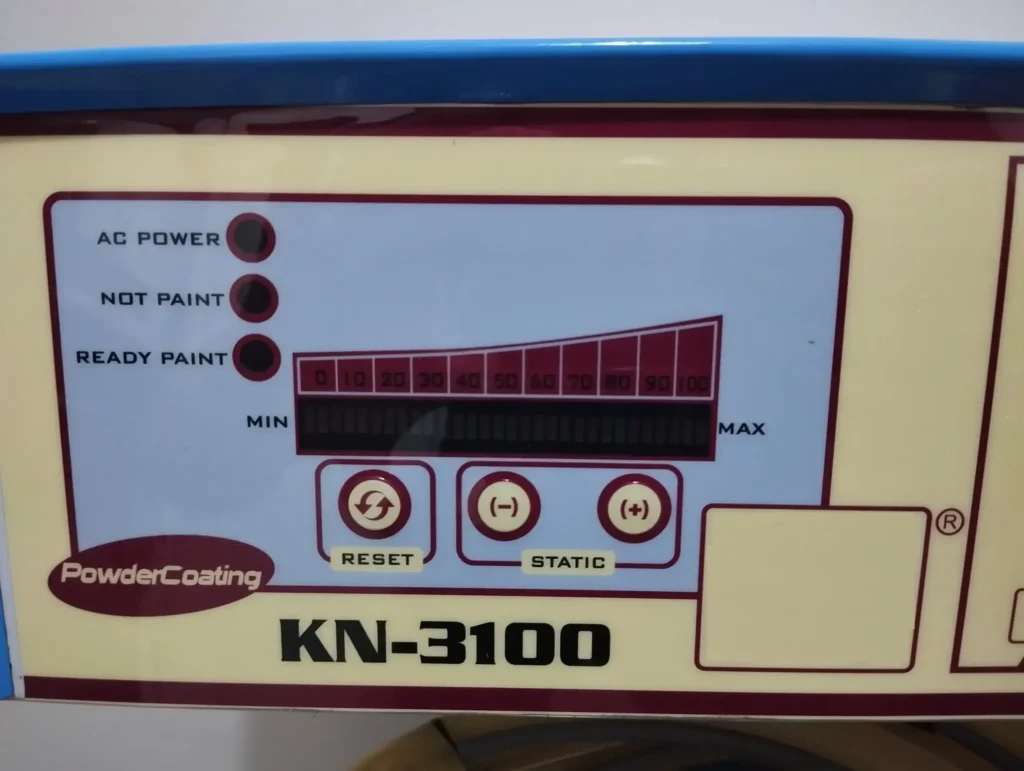

Control Unit of the Powder Coating Machine

The control unit in a powder coating system is a crucial component responsible for managing and regulating various parameters to ensure an effective and consistent coating process. It acts as the brain of the system, allowing operators to adjust and monitor key settings. Here are the key aspects and features of a powder coating control unit:

- Electrostatic Charge Control: The control unit allows operators to adjust the electrostatic charge applied to the powder particles. This adjustment is essential for achieving the desired coating thickness and appearance.

- Voltage and Current Settings: Operators can control the voltage and current levels used in the electrostatic charging process. These settings influence the strength of the electrostatic field and, consequently, the adherence of the powder to the workpiece.

- Powder Flow Rate: The control unit enables operators to adjust the rate at which the powder is fed to the powder gun. This feature is crucial for controlling the coating thickness and ensuring even coverage.

- Preset Programs: Some advanced control units may have preset programs for common coating scenarios. These presets can simplify the setup process and provide a starting point for various types of coatings.

- User Interface: The control unit typically has a user-friendly interface, which may include a digital display, touch screen, or a combination of buttons and knobs. This interface allows operators to input settings, monitor parameters, and make adjustments during the coating process.

- Diagnostic Features: Many control units have diagnostic capabilities to identify and alert operators to potential issues in the system. This helps minimize downtime and allows for quick troubleshooting.

- Interlock and Safety Features: Safety is a critical consideration in powder coating systems. The control unit may include interlock features to ensure that the system operates safely, adhering to established safety protocols.

- Data Logging and Reporting: Advanced control units may have the capability to log data related to the coating process. This data can be useful for quality control, process optimization, and troubleshooting.

- Communication Interfaces: Some control units may include communication interfaces (such as USB, Ethernet, or other protocols) to connect with other devices or a central control system. This allows for integration with larger manufacturing or automation systems.

- Compatibility with Automation: In automated powder coating systems, the control unit is often compatible with robotic or conveyorized systems. This ensures seamless coordination between the powder application process and other production stages.

The control unit plays a crucial role in achieving a consistent and high-quality powder coating finish. It provides operators with the tools and information needed to tailor the coating process to specific requirements and maintain control over various parameters throughout the application.

Powder Recovery System of the Powder Coating Machine

A powder recovery system is an essential component in a powder coating setup, designed to collect and reclaim oversprayed powder during the application process. This system helps minimize waste, reduce environmental impact, and improve the efficiency of powder usage. Here are key features and aspects of a powder recovery system:

- Cyclone Separator: A cyclone separator is a common component in powder recovery systems. It uses centrifugal force to separate the oversprayed powder from the air, directing the powder into a collection container while allowing clean air to be discharged.

- Filter Cartridges: Many powder recovery systems incorporate filter cartridges to capture fine particles that may escape the cyclone separator. The cartridges provide an additional level of filtration to ensure that only clean air is released into the environment.

- Powder Collection Bin: The powder collected by the recovery system is typically deposited into a collection bin or hopper. This bin can be easily accessed for powder retrieval, recycling, or disposal.

- Airflow Control: The recovery system includes mechanisms to control the airflow within the system. Proper airflow management ensures efficient powder separation and collection.

- Automatic Cleaning System: To maintain the efficiency of the filter cartridges, some powder recovery systems are equipped with automatic cleaning mechanisms. These systems use compressed air pulses to dislodge accumulated powder from the filters, keeping them clean and maintaining optimal performance.

- Reclaiming Unit: The recovered powder is often referred to as “reclaimed powder.” Some powder recovery systems have a reclaiming unit that processes the collected powder, removing any impurities or contaminants, and making it ready for reuse in the coating process.

- Sieving System: In the reclaiming process, a sieving system may be used to separate larger particles and contaminants from the reclaimed powder. This helps ensure that the reclaimed powder maintains its quality for future coatings.

- Powder Recirculation: In certain systems, the reclaimed powder can be recirculated back into the main powder feed system. This closed-loop approach contributes to efficient powder usage and minimizes material waste.

- Ease of Maintenance: Powder recovery systems are designed for easy maintenance, with features like quick-release mechanisms for filter replacement, accessible collection bins, and user-friendly interfaces for monitoring and control.

- Environmental Compliance: Powder recovery systems are designed to meet environmental regulations and standards by preventing the release of powder into the atmosphere. This is particularly important in maintaining a clean and safe working environment.

Implementing an effective powder recovery system is critical for businesses engaged in powder coating processes, as it helps optimize powder usage, reduce costs, and promote sustainable and environmentally friendly practices.

Electrostatic Charging

Electrostatic charging is a fundamental principle in the powder coating process. It involves applying an electrostatic charge to the powder particles, creating a force that attracts the charged particles toward the grounded workpiece. This electrostatic attraction ensures even and efficient coverage of the workpiece with the powder coating material. Here’s an overview of the electrostatic charging process in powder coating:

- Principle of Electrostatics:

- Electrostatics is the study of stationary electric charges and the forces they exert. In the context of powder coating, it involves the creation of an electrostatic field between the powder gun and the grounded workpiece.

- Charging the Powder:

- Dry powder coating material is loaded into the powder gun’s hopper. The powder is then conveyed to the gun’s nozzle, where it is subjected to an electrostatic charge. This is typically achieved through the use of a corona charging or triboelectric charging system.

- Corona Charging:

- In corona charging, a high voltage is applied to a charging electrode (corona electrode) near the nozzle. This high voltage ionizes the air around the electrode, creating charged ions. The powder passing through this ionized air becomes electrostatically charged. The charged powder particles are then propelled toward the grounded workpiece.

- Triboelectric Charging:

- Triboelectric charging involves the transfer of electrons between two materials in contact. In the context of powder coating, the powder particles rub against each other or against a charging surface within the gun, resulting in the transfer of electric charges. This charge imbalance leads to electrostatically charged powder particles.

- Grounding the Workpiece:

- The workpiece to be coated is grounded. When the charged powder particles are directed toward the grounded workpiece, they are attracted and adhere to the surface due to electrostatic forces.

- Uniform Coating:

- The electrostatic charge ensures that the powder particles are evenly distributed across the workpiece, covering surfaces, edges, and recesses. This results in a uniform and consistent coating thickness.

- Control of Electrostatic Parameters:

- The electrostatic charge applied to the powder can be controlled by adjusting parameters such as voltage, current, and airflow. These adjustments allow operators to optimize the coating process for different types of workpieces and powder formulations.

- Efficiency and Material Savings:

- Electrostatic charging in powder coating contributes to process efficiency and material savings. The ability to control the electrostatic charge helps minimize overspray and ensures a high transfer efficiency, reducing waste.

Overall, electrostatic charging is a key factor in the success of powder coating applications. It enables precise and controlled deposition of powder, leading to durable and attractive finishes on a variety of surfaces.

Nozzle and Spray Pattern of the Powder Coating Machine

The nozzle and spray pattern in a powder coating system are crucial components that play a significant role in controlling the application of the powder material onto the workpiece. These elements influence the coverage, thickness, and quality of the powder coating. Here’s an overview of the nozzle and spray pattern in powder coating:

- Nozzle Design:

- The nozzle is a component located at the end of the powder gun that shapes and directs the flow of powder particles. Nozzles come in various designs, and the specific type used can impact the characteristics of the spray pattern.

- Cone or Fan Shaped:

- Nozzles can produce either a cone-shaped or fan-shaped spray pattern. A cone-shaped pattern is more circular, while a fan-shaped pattern is more elongated. The choice between the two depends on the shape and size of the workpiece.

- Adjustable Nozzles:

- Some powder coating systems feature adjustable nozzles that allow operators to modify the width and shape of the spray pattern. This adaptability is beneficial when coating different types of surfaces.

- Multiple Nozzle Systems:

- In some powder coating applications, multiple nozzles may be used within the same gun or across different guns. This is common in automated systems where a combination of nozzles can cover complex or large surfaces efficiently.

- Nozzle Size:

- The size of the nozzle opening influences the flow rate of the powder. Different nozzle sizes are suitable for different powder formulations and application requirements.

- Material Compatibility:

- Nozzles are typically made from materials that are compatible with the powder being used. Materials like stainless steel are commonly used due to their durability and resistance to corrosion.

- Ease of Cleaning:

- Nozzles need to be cleaned regularly to prevent clogging and ensure consistent performance. Some nozzle designs facilitate easy disassembly and cleaning.

- Electrostatic Charging:

- The nozzle is often a critical part of the electrostatic charging process. It helps in creating the electrostatic field that charges the powder particles as they pass through.

- Powder Fluidization:

- Some nozzles may incorporate features to assist in the fluidization of the powder. This helps maintain a consistent and free-flowing state of the powder, preventing clumping and ensuring uniform application.

- Powder Cloud Control:

- Nozzles contribute to controlling the dispersion of the powder cloud. This is important for achieving an even and controlled coating on the workpiece.

The spray pattern is the distribution of powder particles as they leave the nozzle and travel towards the workpiece. A well-designed and properly adjusted nozzle ensures that the powder is applied evenly, covering the entire surface of the workpiece and achieving the desired coating thickness. The nozzle and spray pattern, along with other factors like electrostatic charging and powder flow control, collectively contribute to the overall success of the powder coating process.

Voltage and Current Controls

Voltage and current controls in a powder coating system are essential features that allow operators to adjust and regulate the electrostatic charging process. These controls influence the strength of the electrostatic field, affecting how the powder particles adhere to the grounded workpiece. Here’s an overview of voltage and current controls in powder coating:

- Electrostatic Charging Basics:

- In powder coating, the powder particles are given an electrostatic charge before being sprayed onto the workpiece. The workpiece is grounded, creating an electrostatic field that attracts and holds the charged powder particles in place.

- Voltage Control:

- Voltage control is a crucial parameter in the electrostatic charging process. It refers to the potential difference applied between the charging electrode (corona electrode) and the grounded workpiece. The higher the voltage, the stronger the electrostatic field, and the more effectively the powder particles adhere to the workpiece.

- Current Control:

- Current control is another parameter that can be adjusted to influence the electrostatic charging process. It determines the flow of charged ions around the corona electrode. Adjusting the current affects the quantity and intensity of the charge applied to the powder particles.

- Optimizing for Different Conditions:

- Operators can adjust voltage and current settings based on the specific conditions of the powder coating application. Factors such as the type of powder being used, the geometry of the workpiece, and environmental conditions can all influence the ideal voltage and current settings.

- Uniform Coating Thickness:

- Proper adjustment of voltage and current helps achieve a uniform coating thickness. By fine-tuning these parameters, operators can ensure that the electrostatic field is evenly distributed across the workpiece, resulting in consistent powder adhesion.

- Adapting to Different Workpieces:

- Different workpieces may require adjustments to voltage and current settings. Complex shapes, recessed areas, or varying surface orientations may necessitate changes in the electrostatic parameters to achieve optimal coating coverage.

- Corona Control:

- In corona charging systems, where a corona electrode is used to ionize the air around the nozzle, voltage and current controls are essential for regulating the ionization process. This ensures a stable and controlled electrostatic charge on the powder particles.

- System Integration:

- Voltage and current controls are often integrated into the overall control unit of the powder coating system. This allows for centralized control and adjustment of various parameters, streamlining the coating process.

- Safety Considerations:

- While adjusting voltage and current, safety considerations are important. The control unit should have built-in safety features to prevent overcharging or electrical issues that could pose risks to operators or the equipment.

- Process Optimization:

- Continuous monitoring and adjustment of voltage and current settings contribute to process optimization. This is particularly important for achieving efficient powder transfer, minimizing waste, and ensuring a high-quality finish.

In summary, voltage and current controls in a powder coating system provide operators with the ability to fine-tune the electrostatic charging process, optimizing it for different workpieces and application conditions. Proper adjustment of these parameters is crucial for achieving a consistent and high-quality powder coating finish.

Trigger and Triggering Mechanism of the Powder Coating Machine

In a powder coating system, the trigger and triggering mechanism are components that play a role in controlling the application of the powder material. These components are typically part of a manual powder coating gun, allowing the operator to initiate and control the powder spraying process. Here’s an overview of the trigger and triggering mechanism in powder coating:

- Trigger Mechanism:

- The trigger is a manual control located on the powder coating gun, often near the handle. It functions similarly to a trigger on a firearm. When the operator presses the trigger, it initiates the flow of powder from the gun, allowing the powder to be sprayed onto the workpiece.

- On/Off Control:

- The trigger serves as an on/off switch for the powder coating gun. When the trigger is pressed, it activates the powder feed and electrostatic charging system, enabling the powder to be sprayed. Releasing the trigger stops the powder flow, providing control over when and where the powder is applied.

- Variable Flow Control:

- Some powder coating guns have triggers with variable flow control. This means that the amount of powder released can be adjusted by partially depressing or releasing the trigger. This feature allows for finer control over the coating thickness and application rate.

- Ergonomics:

- The design and ergonomics of the trigger are important for user comfort during extended use. A well-designed trigger allows for easy and comfortable operation, reducing operator fatigue.

- Adjustable Trigger Sensitivity:

- In certain powder coating systems, the triggering mechanism may have adjustable sensitivity. This allows operators to customize the level of force required to activate the trigger, accommodating different user preferences.

- Safety Interlocks:

- Some powder coating guns incorporate safety interlocks into the triggering mechanism. These interlocks may require the operator to perform specific actions or meet certain conditions before the trigger can be activated, enhancing overall safety in the workplace.

- Compatibility with Automation:

- In automated or robotic powder coating systems, triggers may be replaced with digital or electronic signals that initiate the powder spraying process. These signals can be integrated into a larger control system for seamless automation.

- Durability and Reliability:

- The trigger and triggering mechanism should be durable and reliable to withstand the demands of the powder coating environment. This includes resistance to wear, corrosion, and exposure to powder particles.

- Quick Release and Reset:

- A quick-release mechanism allows for rapid and easy stopping of powder flow when needed. This feature is useful for color changes, touch-ups, or when moving between different areas of the workpiece.

- Maintenance:

- Regular maintenance is essential for the trigger and triggering mechanism. This may involve cleaning, lubrication, and inspection to ensure proper functionality over time.

The trigger and triggering mechanism are integral to the manual operation of powder coating guns, providing operators with precise control over the application process. These components contribute to the overall efficiency, quality, and user-friendliness of the powder coating system.

Powder Flow Control

Powder flow control is a critical aspect of the powder coating process, ensuring the proper and consistent application of powder material onto the workpiece. Controlling the flow rate of powder is essential for achieving the desired coating thickness, uniform coverage, and overall coating quality. Here’s an overview of powder flow control in a powder coating system:

- Powder Feed System:

- The powder feed system is responsible for delivering the powder coating material from the powder hopper to the powder gun. This system includes components such as hoses, tubes, and a powder feeder that controls the flow of powder.

- Powder Feeder:

- The powder feeder is a crucial component that regulates the flow of powder from the hopper to the powder gun. It is typically equipped with mechanisms to adjust and control the rate at which powder is dispensed.

- Adjustable Flow Rate:

- Powder flow control allows operators to adjust the flow rate of powder based on the requirements of the specific coating application. This adjustment is often achieved through the manipulation of settings on the powder feeder or the overall control unit.

- Consistent Coating Thickness:

- Proper powder flow control is essential for achieving a consistent coating thickness across the entire surface of the workpiece. By maintaining a uniform flow rate, operators can avoid uneven application and achieve a high-quality finish.

- Adapting to Workpiece Characteristics:

- Different workpieces may require adjustments to the powder flow rate. Large or complex shapes, varying surface orientations, and different substrate materials may necessitate changes in the powder flow to achieve optimal coating results.

- Electrostatic Charging Considerations:

- Powder flow control is closely linked to the electrostatic charging process. The flow rate should be synchronized with the charging parameters to ensure that the electrostatic field effectively charges the powder particles, leading to proper adhesion on the workpiece.

- Powder Fluidization:

- Maintaining the fluidization of the powder within the hopper and feeder is essential for consistent flow control. Powder fluidization prevents clumping and ensures that the powder flows smoothly through the delivery system.

- Pressure Control:

- In some powder coating systems, pressure control mechanisms are integrated into the powder feed system. Pressure regulation helps maintain a consistent flow and prevents issues such as pulsations or fluctuations in powder delivery.

- Closed-Loop Systems:

- Some advanced powder coating systems employ closed-loop feedback mechanisms. These systems monitor the powder flow in real-time and automatically adjust settings to maintain the desired flow rate, enhancing precision and efficiency.

- Powder Conservation:

- Efficient powder flow control contributes to powder conservation by minimizing waste. Controlling the flow rate ensures that the right amount of powder is delivered to coat the workpiece without excessive overspray.

Efficient powder flow control is a key factor in achieving a successful powder coating process. It requires coordination with other system components, such as the powder gun, control unit, and powder recovery system, to ensure a seamless and effective coating operation. Proper maintenance and calibration of the powder feed system are also essential for consistent and reliable powder flow control.

Container Design

The term “container design” can refer to various types of containers used in different contexts. In the context of powder coating or related processes, container design typically refers to the design of containers or hoppers that hold and transport materials, such as dry powder coating materials. Here’s an overview of container design considerations in the context of powder coating:

- Material Compatibility:

- Containers used for powder coating should be made from materials that are compatible with the powder being used. Common materials include stainless steel, aluminum, or other materials with properties that resist corrosion, contamination, and facilitate easy cleaning.

- Capacity:

- The capacity of the container is crucial and depends on the volume of powder required for the coating process. Container size is determined by factors such as the size and quantity of workpieces being coated and the duration of the coating operation.

- Powder Fluidization:

- For efficient powder flow, some containers incorporate features for fluidizing the powder. This ensures a consistent and free-flowing state of the powder, preventing clumping and facilitating uniform application.

- Access and Loading:

- Container design should facilitate easy loading of powder into the container. This may involve hinged lids, removable covers, or other access points that allow operators to add or replace powder without significant downtime.

- Level Sensors:

- Containers may include level sensors to monitor the amount of powder present. These sensors help operators know when the powder level is getting low and when it’s time to replenish the supply to avoid interruptions in the coating process.

- Shape and Geometry:

- The shape and geometry of the container can impact the flow characteristics of the powder. Some containers are designed with features that promote even powder flow, preventing powder from accumulating in certain areas.

- Powder Aeration:

- Aeration systems may be incorporated into container designs to keep the powder in a fluidized state. This involves introducing air into the powder to prevent it from settling or compacting, ensuring a consistent powder flow.

- Quick-Release Mechanisms:

- Quick-release mechanisms are useful for easy removal and replacement of containers. This is particularly important for quick color changes or when switching between different powder formulations.

- Cleaning and Maintenance:

- Container design should consider ease of cleaning and maintenance. Smooth surfaces, removable parts, and accessible areas contribute to efficient cleaning procedures, preventing cross-contamination between different powder types.

- Grounding:

- Proper grounding is essential for safety and effective electrostatic charging in the powder coating process. Containers need to be grounded to ensure the efficient transfer of the electrostatic charge to the powder particles.

- Dust Containment:

- Containers should be designed to minimize the escape of powder dust, ensuring a clean and safe working environment. This may involve effective sealing mechanisms and features to contain powder during loading and operation.

The specific design features of containers in a powder coating system may vary based on the type of powder used, the characteristics of the coating process, and the overall system configuration. The goal is to have a container that promotes efficient, reliable, and safe powder handling during the coating operation.

Powder Fluidization

Powder fluidization is a process used in powder coating systems to ensure the consistent and smooth flow of dry powder coating material. It involves introducing air into the powder particles to create a fluid-like state, preventing clumping and promoting uniform application. Here are the key aspects of powder fluidization:

- Purpose of Fluidization:

- The primary purpose of powder fluidization is to maintain the powder coating material in a free-flowing and easily transportable state. This is particularly important in powder coating systems where a continuous and consistent supply of powder is required for the coating process.

- Prevention of Clumping:

- Clumping or caking of powder particles can occur due to factors such as moisture absorption or static electricity. Fluidization helps break up these clumps, ensuring that individual powder particles can be easily transported through the powder delivery system without blockages.

- Uniform Powder Flow:

- Powder fluidization contributes to the creation of a uniform and consistent flow of powder. This is crucial for achieving even coverage during the coating process, especially when using manual or automated powder coating guns.

- Powder Hopper Design:

- Powder hoppers or containers often incorporate features to facilitate fluidization. Some hoppers have porous membranes or aeration devices at the bottom that allow controlled air flow into the powder, promoting fluidization.

- Air Distribution:

- The distribution of air within the powder container is carefully controlled to ensure uniform fluidization. Properly designed aeration systems evenly disperse air, preventing localized areas of excessive or insufficient fluidization.

- Adjustability:

- Powder fluidization systems are often adjustable to accommodate different types of powder materials and application requirements. Operators can control the air flow to achieve the optimal fluidization level for a specific powder formulation.

- Pressure Control:

- In addition to adjusting the air flow, some powder coating systems also allow operators to control the pressure in the powder delivery system. This pressure control further influences the fluidization process and helps maintain a consistent powder flow rate.

- Powder Recirculation:

- In some systems, recirculation of the powder is used to enhance fluidization. The powder is circulated within the system, passing through a fluidization chamber to maintain its fluid-like state before being reintroduced into the powder hopper.

- Level Sensors:

- Powder fluidization systems may be integrated with level sensors to monitor the powder level in the hopper. These sensors help operators ensure a sufficient amount of fluidized powder is available for the coating process.

- Electrostatic Charging Considerations:

- Proper fluidization is essential for effective electrostatic charging. The charged powder particles need to be in a fluidized state to ensure even distribution and adhesion to the grounded workpiece.

Powder fluidization is a critical aspect of powder coating systems, ensuring that the powder remains in an optimal state for application. The design and operation of fluidization systems contribute to the efficiency, quality, and consistency of the powder coating process.

Powder Transfer System

A powder transfer system in powder coating refers to the mechanism responsible for conveying dry powder coating material from the powder hopper or container to the powder gun or applicator. The efficient transfer of powder is essential for a smooth and consistent application of the coating onto the workpiece. Here are the key components and considerations associated with a powder transfer system:

- Powder Feeder:

- The powder feeder is a critical component of the powder transfer system. It controls the flow of powder from the hopper to the powder gun. Powder feeders can be adjustable to regulate the amount of powder being dispensed.

- Hoses and Tubes:

- Hoses and tubes connect the powder feeder to the powder gun, creating a conduit for the powder to travel from the hopper to the application point. These conduits must be designed to prevent clogging and ensure a consistent powder flow.

- Quick-Release Couplings:

- Quick-release couplings facilitate easy assembly and disassembly of the powder transfer system. This feature is essential for quick color changes, maintenance, and cleaning between different powder formulations.

- Powder Recirculation:

- Some powder coating systems incorporate recirculation loops in the transfer system. This involves circulating the powder through the system to maintain optimal fluidization, prevent settling, and ensure a consistent flow.

- Pressure Control:

- Pressure control mechanisms may be integrated into the powder transfer system to regulate the flow of powder. Controlling the pressure helps maintain a consistent powder delivery rate and prevents fluctuations that can affect coating quality.

- Air Assist:

- Air assist systems may be used to aid in the transport of powder through the hoses. Compressed air is introduced to assist in propelling the powder particles, ensuring a smooth and controlled flow.

- Powder Spray Gun:

- The powder spray gun is the endpoint of the powder transfer system, where the powder is applied to the workpiece. The gun typically incorporates features for electrostatic charging, nozzle design, and trigger control.

- Electrostatic Charging:

- Electrostatic charging is often integrated into the powder transfer system. The powder particles are charged before reaching the gun nozzle, ensuring effective adhesion to the grounded workpiece.

- Grounding:

- Proper grounding is crucial in the powder transfer system, especially as it relates to electrostatic charging. Grounding prevents the accumulation of static charges and ensures a safe and effective coating process.

- Vibratory Feeders (Optional):

- In some systems, vibratory feeders may be employed to assist in the controlled release of powder from the hopper. Vibratory action prevents powder particles from clumping and aids in maintaining a uniform flow.

- Closed-Loop Systems (Optional):

- Closed-loop systems use feedback mechanisms to monitor and control the powder transfer process in real-time. This can include sensors and automated adjustments to optimize the powder delivery.

Efficient and reliable powder transfer systems are crucial for achieving high-quality powder coating finishes. The design and operation of these systems are tailored to accommodate different powder characteristics, application requirements, and the specific features of the coating equipment used.

Vibratory Feeders

Vibratory feeders are devices used to convey and meter dry bulk materials, including powders, granules, and other solid materials, in a controlled manner. In the context of powder coating systems, vibratory feeders are sometimes employed to assist in the controlled release of dry powder coating material from the hopper to ensure a consistent and uniform flow. Here are key features and considerations related to vibratory feeders:

- Vibration Mechanism:

- Vibratory feeders generate vibrations that assist in the controlled flow of powder. The vibrations cause the powder particles to move along the feeder tray or channel, preventing clumping and ensuring a more uniform and consistent flow.

- Preventing Bridging and Rat-Holing:

- Bridging and rat-holing are issues where powder particles can form clumps or accumulate in the hopper, leading to uneven flow. Vibratory feeders help prevent these issues by promoting the movement and separation of powder particles.

- Uniform Powder Dispensing:

- The primary goal of using vibratory feeders is to achieve a uniform and controlled dispensing of powder. This is crucial for maintaining consistency in the powder coating process and achieving an even application on the workpiece.

- Adjustable Vibration Settings:

- Vibratory feeders often have adjustable settings for vibration intensity and frequency. Operators can fine-tune these settings to match the characteristics of the specific powder being used, ensuring optimal fluidization and flow.

- Hopper Design:

- The design of the hopper or container that holds the powder is important for proper vibratory feeder operation. Hoppers are often designed with sloped walls or other features to facilitate the flow of powder toward the vibratory feeder tray.

- Material Compatibility:

- Vibratory feeders are typically made from materials that are compatible with the powder being handled. Common materials include stainless steel or other materials with anti-corrosive and easy-to-clean properties.

- Vibratory Feeder Tray Design:

- The design of the vibratory feeder tray influences the powder flow pattern. The tray may have features such as baffles or channels that guide the powder particles in a controlled manner.

- Variable Amplitude and Frequency:

- Some vibratory feeders allow for adjustments in both amplitude (the extent of movement) and frequency (the rate of vibration). This flexibility is valuable for accommodating different powder characteristics and flow requirements.

- Quick Stop Mechanism:

- Vibratory feeders may include quick stop mechanisms to halt the vibration instantly. This feature is useful for applications that require precise control over the timing of powder dispensing.

- Integration with Powder Coating System:

- Vibratory feeders are integrated into the overall powder coating system, often connecting to the powder hopper and feed mechanism. This integration ensures a seamless and synchronized operation with other components of the system.

- Maintenance and Cleaning:

- Regular maintenance is essential to ensure the proper functioning of vibratory feeders. Cleaning and inspection of components help prevent issues such as powder buildup and ensure consistent performance.

Vibratory feeders play a crucial role in promoting the controlled flow of powder in powder coating systems, contributing to the overall efficiency and quality of the coating process.

Quick-Release Mechanisms

Quick-release mechanisms in the context of powder coating systems refer to features that allow for rapid and easy assembly, disassembly, or adjustment of components. These mechanisms are valuable for minimizing downtime, facilitating maintenance, and enabling quick changes in the coating process. Here are some key aspects of quick-release mechanisms in powder coating systems:

- Hopper and Container Quick-Release:

- Powder coating systems often involve containers or hoppers for holding powder coating material. Quick-release mechanisms in this context allow for easy removal and replacement of containers, especially during color changes or when switching between different powder formulations.

- Powder Feeder Quick-Release:

- The powder feeder, which controls the flow of powder from the hopper to the powder gun, may incorporate quick-release features. This allows operators to quickly disconnect and reattach the powder feeder for cleaning, maintenance, or adjustments.

- Hose and Tube Connections:

- Hoses and tubes that convey powder from the hopper to the powder gun may have quick-release couplings. These couplings simplify the process of connecting and disconnecting hoses, facilitating efficient color changes or system maintenance.

- Nozzle and Spray Gun Quick-Release:

- Powder spray guns used in coating systems may feature quick-release mechanisms for nozzles and other components. This enables operators to easily swap nozzles or perform maintenance tasks without requiring extensive downtime.

- Adjustable Components:

- Components that require adjustment during operation, such as nozzles, may incorporate quick-release mechanisms. This allows for swift adjustments and ensures that the coating process can be fine-tuned without significant interruption.

- Quick-Change Systems:

- Some powder coating systems are designed with quick-change features that enable operators to switch between different setups rapidly. This is particularly useful in environments where frequent color changes or variations in coating requirements are common.

- Tool-Free Design:

- Quick-release mechanisms are often designed to be tool-free, meaning that operators can make necessary changes or adjustments without the need for additional tools. This enhances the speed and simplicity of the process.

- Safety Interlocks:

- Quick-release mechanisms may incorporate safety interlocks to ensure that components can only be released or changed when the system is in a safe state. This helps prevent accidents and ensures operator safety.

- Alignment Guides:

- Some quick-release systems include alignment guides or markers to assist operators in correctly repositioning or reconnecting components. This helps maintain accuracy and consistency in the setup.

- Dust Containment:

- Quick-release mechanisms may include features that help contain powder dust during the release or changeover process. This is important for maintaining a clean and safe working environment.

- Integration with Control Systems:

- Quick-release mechanisms are often integrated into the overall control system of the powder coating equipment. This integration allows for coordinated and automated changes in response to system requirements.

Overall, quick-release mechanisms are essential for optimizing the efficiency and flexibility of powder coating systems. By reducing the time and effort required for changes, adjustments, and maintenance, these mechanisms contribute to increased productivity and responsiveness in powder coating operations.

Principle of Electrostatics

Electrostatics is a branch of physics that explores the behavior of electric charges at rest, focusing on the principles and phenomena associated with stationary electric charges. The foundation of electrostatics lies in the fundamental principles of electric charge, force, and potential, which collectively shape the interactions between charged particles. The key principles governing electrostatics include Coulomb’s Law, the principle of superposition, electric fields, electric potential, and capacitance.

Electric Charge: At the heart of electrostatics is the concept of electric charge. There are two types of electric charge: positive and negative. Like charges repel each other, while opposite charges attract. The smallest unit of charge is the elementary charge, denoted by the symbol “e.”

Understanding and applying the principles of electrostatics is crucial in various technological applications, including but not limited to electric circuits, electronic devices, and, as mentioned earlier, powder coating processes, where the controlled application of electrostatic charges plays a central role in achieving uniform and efficient coatings.

Charging the Powder

Charging the powder is a fundamental step in the powder coating process, wherein dry powder particles are given an electrostatic charge before being applied to a grounded workpiece. This electrostatic charging principle plays a critical role in achieving an even and efficient coating. The process involves several key components and steps, contributing to the overall success of the powder coating application.

- Principle of Electrostatic Charging: The principle of electrostatic charging is rooted in the behavior of electric charges. The powder coating system typically uses a corona charging mechanism, where a corona electrode generates a high-voltage field that ionizes surrounding air. The charged air molecules then impart their charge to the powder particles as they pass through the corona field.

- Powder Gun and Corona Electrode: The powder gun, an essential component in the powder coating system, features a corona electrode. This electrode generates a corona discharge, creating a cloud of charged ions around the powder spray nozzle. The powder particles passing through this ionized air acquire an electrostatic charge.

- Triboelectric Charging (Optional): In some powder coating systems, particularly those employing fluidized beds or other variations, triboelectric charging may be used. This occurs when powder particles gain charge through frictional contact with other materials, such as those in the fluidization chamber or the walls of the powder hopper.

- Uniform Charging: Ensuring uniform charging of the powder particles is crucial for achieving consistent coating thickness. The design of the corona electrode, as well as the control of voltage and current parameters, contributes to the uniform distribution of the electrostatic charge on the powder.

- Adjustable Charging Parameters: Powder coating systems often provide operators with the ability to adjust the voltage and current settings for the corona electrode. These adjustments allow for fine-tuning the electrostatic charging process based on the type of powder being used, the workpiece characteristics, and other application-specific requirements.

- Grounding the Workpiece: The workpiece being coated is typically grounded to create an electric field that attracts and holds the charged powder particles. This grounding ensures a consistent and controlled deposition of the powder on the surface of the workpiece.

- Efficiency and Transfer Rate: Efficient electrostatic charging contributes to a high transfer efficiency, where a significant portion of the charged powder adheres to the workpiece. This not only optimizes material usage but also reduces waste and promotes cost-effectiveness in the coating process.

- Powder Cloud Control: The electrostatic charging process also influences the dispersion of the powder cloud. Controlling the powder cloud is essential for preventing overspray and ensuring that the charged particles reach the workpiece without excessive dispersion.

- Safety Considerations: While electrostatic charging is integral to the powder coating process, safety measures are paramount. Systems are designed with safety features to prevent electrical hazards and ensure the well-being of operators and equipment.

- Continuous Monitoring and Optimization: Modern powder coating systems often incorporate sensors and control units to monitor and optimize the electrostatic charging process in real-time. This allows for adjustments on-the-fly, ensuring consistent performance throughout the coating operation.

Charging the powder is a critical step that directly influences the quality, efficiency, and cost-effectiveness of the powder coating process. As technology advances, continuous improvements in charging mechanisms and control systems contribute to the ongoing refinement of powder coating applications across various industries.

Corona Charging

Corona charging is a pivotal electrostatic powder coating technique that plays a central role in achieving efficient and uniform powder deposition on surfaces. This process involves the generation of a corona discharge, creating a charged field that ionizes surrounding air. The charged air, in turn, imparts an electrostatic charge to the powder particles as they pass through this corona field. Corona charging is widely utilized in powder coating systems due to its effectiveness in producing a controlled and even distribution of charged particles, ensuring high transfer efficiency and a superior coating finish.

One of the key components in a powder coating system employing corona charging is the corona electrode, typically integrated into the powder spray gun. The corona electrode is designed to generate a high-voltage electric field in its vicinity. This field ionizes the air molecules in the surrounding atmosphere, creating a corona or halo of charged ions. The electrostatically charged powder particles passing through this corona discharge zone acquire a similar charge due to the ionized air.

The efficiency of corona charging is influenced by various factors, and one critical parameter is the adjustment of voltage and current settings for the corona electrode. Operators have the flexibility to fine-tune these parameters based on the specific characteristics of the powder being used, the geometry of the workpiece, and other application-specific requirements. Proper adjustment ensures a consistent and controlled electrostatic charge on the powder particles, contributing to uniform coating thickness and optimal material usage.

Corona charging systems offer several advantages in powder coating applications. One notable advantage is their suitability for coating complex and irregularly shaped workpieces. The electrostatic charge imparted to the powder particles allows them to be attracted to and adhere uniformly to surfaces, even in recessed areas or on intricate geometries. This capability is particularly valuable in industries where diverse parts with varying shapes and sizes require precision coating.

Additionally, corona charging facilitates high transfer efficiency, meaning a significant proportion of the charged powder adheres to the workpiece, minimizing waste and enhancing cost-effectiveness. The controlled and predictable nature of corona charging contributes to the overall quality and consistency of the coating process, resulting in a smooth and durable finish.

While corona charging is a highly effective and widely used method, it is essential to consider safety aspects. Adequate measures, such as grounding the workpiece and incorporating safety features in the system, are crucial to prevent electrical hazards and ensure a secure operating environment for operators and equipment.

In summary, corona charging is a cornerstone technology in electrostatic powder coating, providing a reliable and efficient means of imparting an electrostatic charge to powder particles. Its adaptability to various powder formulations, coupled with the ability to coat complex surfaces with precision, makes corona charging a preferred method in industries ranging from automotive to appliances, where high-quality finishes and consistent coatings are paramount.

Triboelectric Charging

Triboelectric charging is a phenomenon and a fundamental principle in electrostatics that involves the generation of electric charge through the contact and separation of materials. The term “triboelectric” is derived from the Greek words “tribos,” meaning rubbing or friction, and “ēlektron,” meaning amber. The triboelectric effect has been known since ancient times, with the observation that certain materials, when rubbed together, exhibit an ability to attract lightweight objects like bits of straw or feathers.

The triboelectric charging process occurs due to the transfer of electrons between two different materials with different affinities for electrons. When these materials come into contact and then are separated, electrons are exchanged, leading to an imbalance of charges on the surfaces of the materials. The material that gains electrons becomes negatively charged, while the one that loses electrons becomes positively charged.

In the context of powder coating, triboelectric charging is employed as an alternative method to corona charging. In a triboelectric powder coating system, the charging of the powder particles occurs through frictional contact with other materials within the system. This can include contact with surfaces such as those in a fluidized bed, the walls of a hopper, or other components designed to induce triboelectric charging.

Key aspects of triboelectric charging in powder coating systems include:

- Mechanism of Charging: The triboelectric charging process relies on the mechanical contact and separation of materials. Powder particles, as they move and interact within the coating system, experience frictional forces that lead to the transfer of electric charges between the particles and the surfaces they contact.

- Material Selection: The choice of materials in contact with the powder influences the triboelectric charging efficiency. Materials with different electron affinities and surface characteristics can enhance or diminish the triboelectric effect.

- Uniformity of Charging: Achieving uniform charging of powder particles is crucial for consistent coating thickness and quality. The design of the system components, such as fluidization chambers or hoppers, plays a role in ensuring that powder particles experience consistent triboelectric interactions.

- Adaptability to Various Powders: Triboelectric charging is versatile and can be adapted to various types of powder formulations. This adaptability allows for the application of triboelectric charging in a wide range of industries and coating requirements.

- Complex Geometries: Triboelectric charging is particularly useful in coating applications involving complex and irregularly shaped workpieces. The charged powder particles are attracted to the grounded workpiece, even in recessed or hard-to-reach areas, resulting in a more uniform coating.

- Reduced Overspray: Compared to corona charging, triboelectric charging is often associated with reduced overspray. The charged particles have a higher tendency to adhere to the workpiece, minimizing waste and contributing to higher transfer efficiency.

- System Design and Optimization: The design of the powder coating system, including the selection of materials and the geometry of components, is crucial for optimizing the triboelectric charging process. Factors such as airflow, particle dynamics, and contact surfaces need to be carefully considered.

While triboelectric charging offers several advantages, it is essential to acknowledge its limitations. Factors such as humidity, temperature, and the specific characteristics of the materials involved can influence the triboelectric effect. Additionally, the control and adjustment of triboelectric charging parameters may require a deeper understanding of the materials and their interactions within the coating system.

In conclusion, triboelectric charging remains a valuable and versatile method in powder coating applications. Its ability to coat complex geometries with reduced overspray makes it well-suited for certain industrial processes, complementing other electrostatic powder coating techniques like corona charging. Ongoing research and advancements in materials science and system design continue to refine and expand the applications of triboelectric charging in the field of powder coating.

Grounding the Workpiece

Grounding the workpiece is a critical and foundational principle in the electrostatic powder coating process, contributing significantly to the effectiveness, safety, and overall success of the coating operation. The grounding principle ensures a controlled and efficient deposition of charged powder particles onto the surfaces of the workpiece, promoting uniform coverage and adhesion.

- Foundation of Electrostatics: Grounding the workpiece is rooted in the fundamental principles of electrostatics. When an object is grounded, it is electrically connected to the Earth, allowing the free flow of electric charge. In the context of powder coating, the workpiece is typically connected to a grounding electrode or the grounding system of the coating equipment.

- Creation of Electric Field: Grounding the workpiece creates an electric field that influences the movement of charged powder particles. The workpiece, being at a constant potential, becomes an attractor for the charged particles, facilitating their controlled migration from the powder gun to the workpiece surfaces.

- Attracting Charged Powder Particles: Charged powder particles are propelled from the powder gun toward the grounded workpiece due to the electrostatic forces at play. The attraction is based on the principle that opposite charges attract; the positively charged powder particles are drawn to the negatively charged workpiece.

- Uniform Powder Deposition: Grounding the workpiece is crucial for achieving uniform powder deposition. The electric field created by the grounded workpiece ensures that the charged powder particles are distributed evenly across the surfaces, including recessed or hard-to-reach areas.

- Minimizing Overspray: Grounding the workpiece helps minimize overspray, a situation where charged particles miss the target and disperse into the surrounding air. When the workpiece is properly grounded, the electrostatic forces guide the charged particles to the surfaces, reducing waste and optimizing material usage.

- Enhancing Transfer Efficiency: Transfer efficiency, a measure of how well the powder adheres to the workpiece, is significantly enhanced through proper grounding. The grounded workpiece acts as a receptive surface, ensuring that a high percentage of charged particles successfully adhere to the surfaces.

- Safety Considerations: Grounding is a critical safety measure in powder coating systems. It prevents the accumulation of excess charge on the workpiece, reducing the risk of electrostatic discharge (ESD) and ensuring the safety of operators and equipment.

- Grounding Techniques: Various techniques are employed to ensure effective grounding of the workpiece. This may involve direct physical contact with grounding hooks or clamps, ensuring that the workpiece is electrically connected to the grounding system of the coating equipment.

- Material Compatibility: The choice of materials for the workpiece can impact the effectiveness of grounding. Conductive materials are preferred for optimal grounding, and non-conductive or insulating materials may require additional considerations or modifications.

- Continuous Grounding: Grounding should be maintained throughout the entire coating process. Any interruption in grounding can lead to uneven powder deposition and compromise the quality of the coating. Systems often incorporate features to ensure continuous and reliable grounding.

- Integration with System Components: Grounding is integrated into the overall design of the powder coating system, ensuring that the powder gun, powder feed system, and other components are properly synchronized to maintain the desired electrostatic conditions.

Grounding the workpiece is a fundamental aspect of electrostatic powder coating, contributing to the efficiency, quality, and safety of the coating process. As technology advances, ongoing developments in grounding techniques and system design continue to refine and optimize the application of this principle in various industrial settings.

Uniform Coating

Uniform coating is a critical objective in the field of surface finishing, particularly in processes such as electrostatic powder coating. Achieving a uniform coating involves the even and consistent application of coating material across the entirety of a substrate or workpiece. This objective is paramount in ensuring both the aesthetic appeal and functional performance of the coated surfaces. Several factors contribute to the attainment of a uniform coating, ranging from the characteristics of the coating material to the design of the coating equipment and the control of environmental conditions.

- Coating Material Properties: The properties of the coating material itself play a significant role in achieving uniformity. Powder coatings, for instance, should be formulated to have consistent particle size, flowability, and electrostatic chargeability. This ensures that, when applied, the coating adheres uniformly to the surface without clumping or uneven distribution.

- Proper Surface Preparation: The substrate’s surface condition is crucial for uniform coating adhesion. Adequate cleaning, degreasing, and any necessary pre-treatments ensure a smooth and contamination-free surface, preventing issues such as fisheyes or uneven coating adhesion.

- Controlled Powder Delivery: In electrostatic powder coating, where an electric charge is imparted to the powder particles before application, controlled powder delivery is essential. This involves precise regulation of the powder flow rate, ensuring a consistent supply of charged particles for deposition on the workpiece.

- Even Electrostatic Charging: Uniform coating heavily relies on the electrostatic charging process. Whether using corona charging or triboelectric charging methods, the charging mechanism must be carefully controlled to ensure that all powder particles receive a uniform charge, leading to consistent attraction to the grounded workpiece.

- Grounding the Workpiece: Proper grounding of the workpiece is critical in guiding the charged particles to the surfaces. Without effective grounding, the electrostatic forces may result in uneven distribution, leading to areas with excess powder or insufficient coverage.

- Optimized Spray Gun Design: The design of the powder spray gun is a key factor in achieving uniform coating. The nozzle geometry, spray pattern, and the ability to control the direction of the spray influence how the powder is distributed onto the workpiece. Well-designed spray guns contribute to consistent coverage.

- Airflow and Environmental Conditions: The ambient conditions within the coating environment, including airflow and temperature, can impact coating uniformity. Proper ventilation and control of environmental factors help prevent issues such as overspray, uneven curing, or powder agglomeration.

- System Calibration and Monitoring: Regular calibration and monitoring of the powder coating system are essential for maintaining uniformity. This includes verifying and adjusting the equipment settings, ensuring that the powder delivery and electrostatic charging mechanisms are operating optimally.

- Application Techniques: The technique used for applying the coating can influence uniformity. Whether employing manual or automated application methods, operators should follow recommended application procedures, ensuring a consistent and controlled process.

- Quality Control Measures: Implementing quality control measures involves inspecting coated surfaces for any irregularities or defects. This may include visual inspections, film thickness measurements, or other testing methods to verify that the coating meets specified standards.

- Feedback and Adjustments: Continuous improvement in achieving uniform coating involves a feedback loop. Analyzing coating results, addressing any non-uniformities, and making necessary adjustments to the process contribute to ongoing optimization.

Uniform coating is not only a visual requirement for aesthetic purposes but also a performance necessity. In industries such as automotive, aerospace, and appliances, where coatings serve functional and protective roles, achieving uniformity is critical to ensuring durability, corrosion resistance, and overall product quality. As technologies evolve, ongoing research and advancements in coating materials, equipment design, and application techniques contribute to the continued improvement of uniform coating processes.

Control of Electrostatic Parameters

The control of electrostatic parameters is a crucial aspect of various industrial processes, particularly in applications such as electrostatic powder coating. The precise management of these parameters is essential for achieving optimal coating quality, efficiency, and safety. Electrostatic parameters encompass a range of factors that influence the behavior of electric charges and the interaction between charged particles, ensuring controlled deposition onto surfaces. A thorough understanding and meticulous control of these parameters are fundamental to the success of electrostatic processes.

- Voltage Settings: Voltage is a primary electrostatic parameter that influences the intensity of the electric field and the strength of the charge imparted to the coating material. The voltage setting on the corona electrode or other charging mechanisms must be carefully controlled. Adjustable voltage allows operators to fine-tune the electrostatic charging process based on the specific characteristics of the coating material and the requirements of the workpiece.

- Current Regulation: Current regulation is vital for controlling the flow of electric charge during the electrostatic charging process. It is essential to maintain a balance that ensures effective charging without causing excessive current that could lead to issues such as arcing or equipment damage. Regulating current contributes to the stability and safety of the electrostatic system.

- Grounding: Proper grounding is a fundamental parameter in electrostatic processes, especially in applications like powder coating. Grounding provides a reference point for the electric potential, ensuring that the charged particles are attracted to and adhere uniformly to the grounded workpiece. Effective grounding minimizes the risk of electrostatic discharge and enhances the overall efficiency of the coating process.

- Charge Density: Charge density refers to the quantity of electric charge per unit area. Controlling charge density is crucial for achieving uniform coating thickness. The density of charged particles should be optimized to prevent overloading or undercoating on different sections of the workpiece, contributing to a consistent finish.

- Powder Flow Rate: In powder coating applications, the rate at which the powder flows through the system is a critical parameter. Controlling the powder flow rate ensures a consistent supply of charged particles to the workpiece, preventing issues such as uneven coating or insufficient coverage.

- Spray Gun Settings: The design and settings of the powder spray gun influence the dispersion and pattern of the charged particles. Adjustable parameters, such as nozzle geometry and spray pattern, allow operators to customize the application for different workpiece geometries, contributing to uniform coating.

- Environmental Conditions: Environmental factors, including temperature and humidity, can impact electrostatic parameters. Controlling these conditions is essential for maintaining the stability of the electrostatic charging process. Humidity levels, for example, can influence the triboelectric charging process in certain applications.

- Feedback Systems: Incorporating feedback systems and sensors into the electrostatic process allows for real-time monitoring and adjustments. These systems provide data on coating thickness, particle dispersion, and other relevant parameters, enabling operators to make informed decisions and optimize the process dynamically.

- Safety Interlocks: Safety interlocks are mechanisms that ensure the electrostatic system operates within safe parameters. They may include features that automatically shut down the system in the event of abnormal conditions, preventing hazards such as excessive voltage or current.

- Material Characteristics: Understanding the characteristics of the coating material is crucial for effective electrostatic control. Different materials may require adjustments in voltage, current, or other parameters to achieve optimal charging and adhesion.

- System Calibration: Regular calibration of the entire electrostatic system is essential for maintaining accuracy and consistency. This involves verifying the accuracy of voltage and current readings, checking equipment performance, and ensuring that all components operate within specified tolerances.

The control of electrostatic parameters is a dynamic process that involves a combination of technological advancements, operator expertise, and continuous monitoring. As industries evolve, research and development efforts focus on refining electrostatic control systems, contributing to improved efficiency, sustainability, and the overall quality of coated products. The integration of smart technologies and automation further enhances the precision and reliability of electrostatic processes in diverse industrial applications.

The EMS manual coating equipment must be connected in accordance with the setup and connection instructions (Please also review the operating instructions for the manual gun control unit).

When a color change takes place, the individual components of the manual coating equipment must be cleaned carefully. All powder particles of the former color must be removed during this process! The following describes an ‘extreme’ color change (light to dark).

Powder coating is increasingly accepted as the preferred finishing process for many applications. Increasingly stringent environmental regulations, rising costs in all areas, and demands by consumers for better quality and more durable products are among the challenges facing today’s finishers. Powder coatings provide a solution to these challenges and others. Powder coating is the technique of applying dry paint to the component.

The powdered paint is normally applied by using a powder feed system and gun to electrostatically charge and spray the powder onto the part. For some applications, the part being coated is dipped into a fluidized bed of powder. The coated part is then heated in an oven, or via infrared panels, to melt and cure the paint. During the curing process, a chemical cross-linking reaction is triggered and it is this chemical reaction that gives the powder coatings many of their desirable properties.

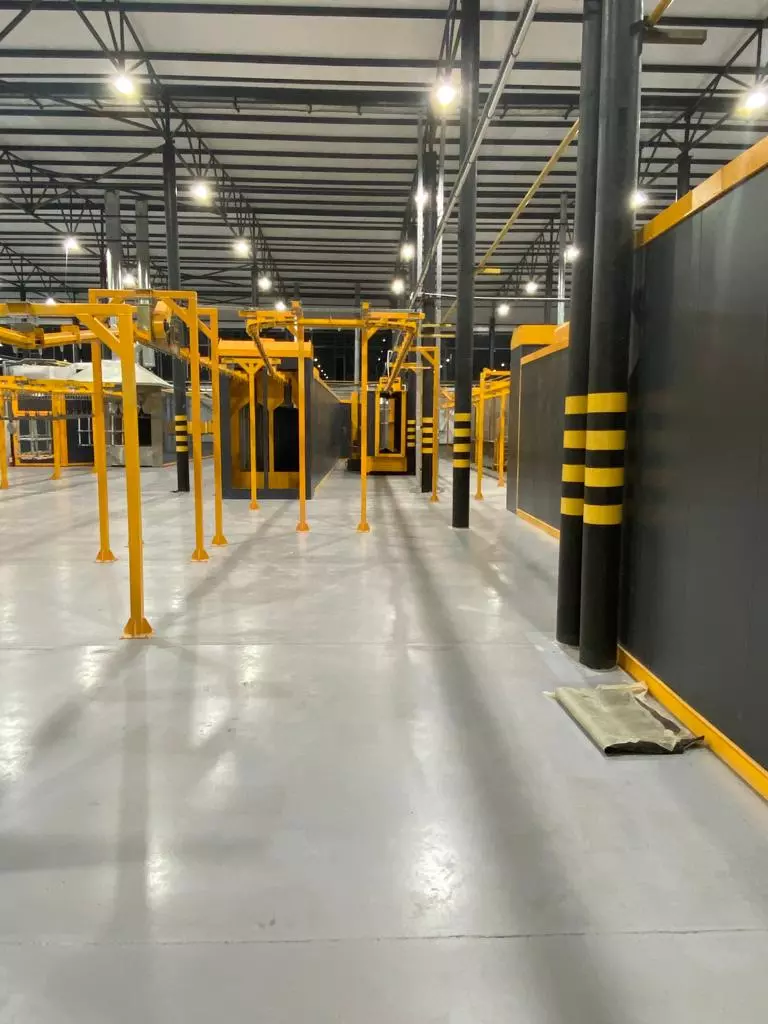

Powder coating has revolutionized the way industries apply finishes to their products, offering a highly durable, long-lasting, and environmentally friendly alternative to traditional liquid paint. This process involves applying a dry powder — typically composed of finely ground resins and pigments — which is electrostatically charged before being sprayed onto a surface. Once applied, the powder is cured under heat, forming a strong bond that resists corrosion, weathering, and wear.

At the heart of this process is powder coating equipment, which plays a critical role in ensuring the quality and efficiency of the coating process. Whether for small-scale workshops or large industrial plants, choosing the right equipment can significantly impact production outcomes, energy consumption, and the final appearance of the coated product.

For businesses looking to achieve the best results, EMS Powder Coating Equipment stands out as a leader in the field, providing innovative, high-performance systems that are built to last. With a strong focus on precision, reliability, and ease of use, EMS has earned a reputation for manufacturing the industry’s most trusted powder coating equipment. In this guide, we’ll explore the different components of powder coating systems, their benefits, and why EMS Powder Coating Equipment is the top choice for any powder coating needs.

What is Powder Coating?

Powder coating is a dry finishing process that has gained widespread popularity due to its durability, versatility, and eco-friendly nature. Unlike liquid paint, which requires a solvent to keep the binder and filler in liquid form, powder coating is applied as a free-flowing, dry powder. This powder is usually composed of thermoplastic or thermoset polymer resins mixed with curatives, pigments, leveling agents, flow modifiers, and other additives to ensure a smooth and protective finish.

One of the biggest advantages of powder coating is its ability to create a thicker and more consistent finish without running or sagging. This results in a more uniform appearance and a stronger bond with the material being coated. Powder coating is particularly favored in industrial applications, where components need to withstand heavy use, exposure to the elements, or high temperatures. Surfaces that can be coated include metal, aluminum, steel, glass, and even some plastics.

There are several benefits to using powder coating over traditional paint. Powder coatings are extremely durable and resistant to corrosion, UV rays, and wear, making them ideal for both indoor and outdoor applications. Additionally, because no solvents are used, powder coating emits negligible volatile organic compounds (VOCs), making it much safer for workers and the environment. The overspray can be easily collected and reused, contributing to minimal waste.

With the right equipment, companies can achieve these outstanding benefits. EMS Powder Coating Equipment offers the most advanced systems, ensuring maximum efficiency in the application process and superior finish quality.

Key Components of Powder Coating Equipment

Powder coating equipment consists of several essential components that work together to ensure a flawless, durable finish. Each piece of equipment plays a specific role in the powder coating process, and the quality of each component directly affects the overall performance and efficiency of the coating line.

Below are the most important components of a powder coating system:

1. Application System: Electrostatic Spray Guns