Powder Coat Bolts: A fastener coating machine is a specialized piece of industrial equipment designed for the application of protective or functional coatings to fasteners such as screws, bolts, nuts, and other hardware components. These machines are integral to industries where fasteners require enhanced corrosion resistance, improved aesthetics, or other surface properties to meet stringent performance standards. The coatings applied typically include zinc plating, phosphating, Teflon, or other specialized materials, depending on the end-use application and environmental requirements.

The design of a fastener coating machine is tailored to provide uniform application, high throughput, and efficient operation. Typically, the process begins with the loading of fasteners into the machine. This can be done manually or through automated feeding systems, depending on the scale of the operation and the machine’s configuration. Once the fasteners are inside the system, they often undergo a pre-treatment process, which may include cleaning, degreasing, or surface activation. This step is crucial to ensure that the coating adheres properly to the fasteners, providing long-lasting performance.

The actual coating process varies based on the type of coating being applied. In electroplating systems, for example, fasteners are immersed in a chemical bath where an electrical current is passed through, depositing a thin, uniform layer of metal onto the surface. Alternatively, in spray-coating systems, fasteners are tumbled or rotated while being sprayed with a liquid or powder coating material, ensuring all surfaces are evenly covered. For more advanced applications, dip-spin coating may be employed, wherein fasteners are submerged in a coating solution and then centrifuged to remove excess material, leaving a uniform layer.

Temperature control and curing are critical in many coating processes. Once the coating is applied, the fasteners are often subjected to heat treatment or baking in curing ovens to solidify the coating and enhance its durability. These ovens are designed to maintain precise temperature and time settings, ensuring the coating’s properties meet specifications.

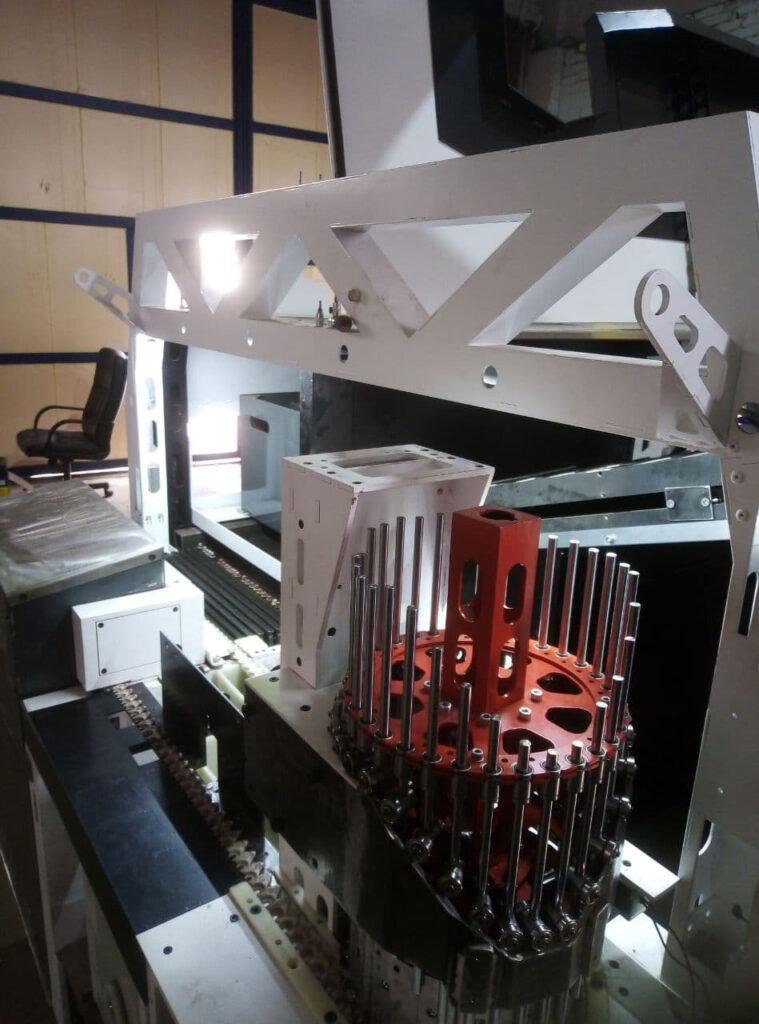

Fastener Coating Machine

Fastener coating machines are engineered with a focus on efficiency and quality. Features such as automated controls, programmable settings, and real-time monitoring are often integrated to enhance operational performance. Safety mechanisms, such as emergency stops and protective enclosures, are also included to ensure worker safety and compliance with industrial standards.

The choice of coating machine depends on several factors, including the type and size of fasteners, the desired coating material, production volume, and specific industry requirements. Industries such as automotive, aerospace, construction, and marine rely heavily on coated fasteners, making these machines a vital part of the manufacturing process. Moreover, advancements in coating technology, such as eco-friendly coatings and nanotechnology, continue to influence the design and functionality of these machines, ensuring they remain at the forefront of industrial innovation.

Another critical aspect of fastener coating machines is their ability to accommodate various fastener geometries and sizes. Fasteners come in a wide range of shapes, lengths, and diameters, from tiny screws used in electronics to large bolts for heavy industrial applications. This variability necessitates a high degree of flexibility in the design of coating machines. Adjustable settings, interchangeable parts like drums, and modular designs allow manufacturers to handle diverse product lines with minimal downtime for reconfiguration. Advanced machines can also automatically detect the size and shape of the fasteners, adjusting application parameters for optimal results.

Environmental considerations are increasingly shaping the development and operation of fastener coating machines. The use of chemical-based coatings often generates waste, requiring systems to include features for recycling and waste treatment. Efforts to reduce the environmental impact of these machines have led to innovations like closed-loop systems that recover excess coating material and energy-efficient curing ovens. Additionally, the transition to water-based or low-VOC (volatile organic compound) coatings is gaining momentum, aligning with stricter environmental regulations and sustainability goals.

Automation plays a significant role in enhancing the productivity of fastener coating machines. Modern systems are equipped with robotic arms, conveyors, and automated sorting mechanisms to streamline the handling of fasteners throughout the process. Integration with Industry 4.0 technologies, such as sensors and IoT-enabled devices, allows for real-time monitoring and control. Operators can track parameters like coating thickness, temperature, and cycle times remotely, ensuring consistency and reducing the likelihood of defects. Predictive maintenance features, powered by machine learning algorithms, can identify potential issues before they cause downtime, further boosting efficiency.

Quality control is a vital part of the fastener coating process. High-precision equipment like thickness gauges, optical scanners, and x-ray fluorescence (XRF) analyzers are often integrated into coating systems or used in post-process inspections. These tools ensure that the coating adheres to specified tolerances, providing a consistent protective layer across all fasteners. In industries with stringent safety and performance standards, such as aerospace and medical devices, rigorous testing and certification protocols are mandatory.

The economics of fastener coating machines also influence their adoption and operation. Capital investment, operating costs, and maintenance requirements must align with the production goals and budget of the manufacturer. Machines designed for high-volume production typically justify their cost through economies of scale, while smaller operations may prioritize versatility and low-maintenance designs. Some manufacturers offer leasing or rental options, providing a cost-effective way for smaller companies to access advanced coating technologies.

Finally, the future of fastener coating machines is poised to embrace further advancements in material science and automation. Developments in nanocoatings and self-healing materials promise to revolutionize the durability and functionality of coated fasteners. The integration of artificial intelligence for process optimization and defect detection is another promising avenue. As industries continue to demand more from their fasteners—whether it’s resistance to extreme temperatures, chemical exposure, or mechanical stress—coating machines will evolve to meet these challenges, cementing their role as a cornerstone of modern manufacturing.

Another exciting trend in the development of fastener coating machines is the growing emphasis on customization and modularity. Manufacturers are increasingly seeking equipment that can be tailored to their specific needs without sacrificing efficiency. Modular designs allow for the addition or removal of process components, enabling operators to configure machines for different coating methods, curing processes, or production capacities. For example, a machine could include interchangeable drums for dip-spin coating, an additional spray unit for detailed surface finishing, or a separate curing module for high-temperature requirements. This flexibility not only accommodates diverse production demands but also extends the machine’s lifespan, as it can be adapted to new requirements over time.

Energy efficiency is another area where significant improvements are being made. Coating processes, particularly those involving curing ovens or electroplating baths, can be energy-intensive. Modern machines are being designed to minimize energy consumption through advanced heating systems, better insulation, and optimized process cycles. Some machines utilize heat recovery systems that capture waste heat from curing ovens and redirect it to preheat incoming fasteners or maintain the temperature of chemical baths. Additionally, the adoption of LED-based UV curing systems in specific applications has dramatically reduced energy requirements while providing precise control over curing times.

Digital transformation in the form of smart manufacturing is revolutionizing how fastener coating machines are operated and managed. Internet of Things (IoT) connectivity enables these machines to communicate with other equipment in a production line, creating a seamless workflow. Data analytics and machine learning are employed to optimize production parameters dynamically, reducing material waste and energy usage. Digital twins—virtual replicas of the machines—allow operators to simulate processes, test new configurations, and predict outcomes before making changes in real-world settings. This reduces downtime and enhances the precision of operations, ultimately leading to higher-quality coated fasteners.

Health and safety improvements have also become a priority in the design of fastener coating machines. The use of hazardous chemicals and high temperatures poses risks to operators, prompting the incorporation of advanced safety measures. Enclosed systems with integrated ventilation reduce exposure to fumes, while automated chemical handling minimizes the need for manual intervention. Emergency shutdown features, interlock systems, and fail-safe mechanisms provide additional layers of protection. Training and user-friendly interfaces are also emphasized to ensure operators can manage the machines effectively while maintaining a safe working environment.

Customer support and after-sales service are becoming integral to the value proposition of fastener coating machines. Manufacturers are offering comprehensive service packages that include installation, training, regular maintenance, and remote troubleshooting. Predictive maintenance systems, enabled by IoT sensors and analytics, are particularly beneficial, as they allow manufacturers to address potential issues before they lead to costly breakdowns. Some companies also provide software updates to ensure that the machines stay compatible with the latest digital advancements and industry standards.

As global supply chains become more interconnected, fastener coating machines are increasingly expected to support traceability and compliance. Coated fasteners often need to meet specific regulatory requirements, such as RoHS (Restriction of Hazardous Substances) compliance in electronics or salt spray resistance for marine applications. Machines equipped with integrated marking systems and data tracking capabilities can automatically record process details for each batch, providing a clear audit trail. This not only ensures compliance but also enhances quality assurance by enabling manufacturers to trace defects back to their source.

In summary, fastener coating machines are critical to modern manufacturing, offering a blend of precision, efficiency, and adaptability. The ongoing advancements in automation, material science, and environmental sustainability are shaping the future of these machines, ensuring they remain indispensable tools for industries ranging from automotive to aerospace. As manufacturers continue to demand higher-quality fasteners with advanced surface properties, the evolution of coating technology will undoubtedly rise to the challenge, driving innovation and improving overall production capabilities.

The role of fastener coating machines in sustainability is becoming increasingly significant as industries aim to reduce their environmental impact. Modern machines are incorporating eco-friendly technologies to align with global sustainability goals. For instance, water-based coatings and low-VOC (volatile organic compound) formulations are gaining prominence, offering a safer and more environmentally friendly alternative to traditional solvent-based coatings. These innovations not only reduce harmful emissions but also improve workplace safety by minimizing operator exposure to hazardous chemicals.

Waste management is another critical focus in sustainable coating operations. Fastener coating machines are now equipped with systems to minimize waste, such as recycling and reclaiming excess coating materials during the application process. In dip-spin systems, for example, excess coating is collected and reused, significantly reducing material waste and lowering operational costs. Effluent treatment systems are also integrated to handle chemical waste responsibly, ensuring compliance with environmental regulations and preventing contamination of water sources.

Coating machines are also benefiting from advances in surface preparation technologies, which are essential for achieving strong adhesion and long-lasting performance of the coating. Techniques such as shot blasting, acid pickling, and ultrasonic cleaning are used to remove impurities and create a surface profile that enhances the bonding of the coating material. Some machines integrate these surface preparation steps into the overall process flow, streamlining operations and ensuring consistent quality. Innovations in surface preparation, such as plasma treatment, are emerging as precise and environmentally friendly alternatives for preparing fasteners.

The industry is witnessing a growing demand for multi-functional coatings, which has led to the development of machines capable of applying complex, layered coatings. For example, fasteners used in automotive and aerospace applications often require coatings that provide corrosion resistance, wear resistance, and low friction simultaneously. To meet this demand, some machines are designed to apply multiple layers of coatings in a single cycle, each layer serving a specific purpose. This capability reduces processing time and ensures that the final product meets the rigorous performance standards required in these industries.

Customization of coating properties

Customization of coating properties is a key area where fastener coating machines are evolving to meet diverse industry needs. Different applications demand coatings with specific characteristics, such as enhanced corrosion resistance, thermal stability, electrical conductivity, or anti-galling properties. For instance, fasteners in the marine industry require coatings that can withstand prolonged exposure to saltwater and humidity, while those used in electronics may need non-conductive or anti-static finishes. Modern coating machines allow manufacturers to fine-tune parameters like coating thickness, material composition, and curing time to achieve these tailored properties. This precision ensures that fasteners perform optimally in their intended environments.

The integration of advanced metrology tools within coating machines further supports this customization. Real-time measurement systems, such as laser scanners or eddy current sensors, can monitor coating thickness during the application process, ensuring uniformity and adherence to specifications. These systems are particularly beneficial in industries like aerospace and medical devices, where even minor inconsistencies in coating thickness can compromise safety and performance. By automating these quality control measures, coating machines reduce the need for post-processing inspections and rework, saving time and resources.

The rise of hybrid coating technologies is another transformative trend. Hybrid systems combine multiple application methods, such as electroplating and powder coating, within a single machine. This approach allows for the creation of composite coatings that offer a combination of desirable properties, such as a hard, wear-resistant outer layer and a corrosion-resistant underlayer. These machines are particularly valuable for high-performance applications, such as automotive drivetrains or industrial machinery, where fasteners are subjected to extreme stress and environmental conditions.

Another area of innovation is the development of self-healing coatings. These advanced materials can repair minor damage to the coating layer, such as scratches or micro-cracks, by using embedded microcapsules or responsive polymers that activate under specific conditions. Coating machines designed to handle these materials require precise application techniques to ensure the uniform distribution of self-healing agents. While still an emerging technology, self-healing coatings have the potential to significantly extend the lifespan of fasteners and reduce maintenance requirements.

Operational efficiency remains a cornerstone of fastener coating machine development. High-speed systems are being designed to handle large volumes of fasteners without compromising quality. These machines often incorporate sophisticated sorting and feeding mechanisms to ensure continuous operation. For example, vibratory feeders or magnetic conveyors can align fasteners for coating, while robotic arms or pick-and-place systems can handle complex geometries. Such automation not only increases throughput but also reduces labor costs and minimizes the risk of human error.

The shift toward compact and portable coating machines is gaining traction in industries where space constraints or mobility are critical factors. Compact designs are particularly useful for small-scale manufacturers or on-site operations, such as construction projects or offshore platforms, where coated fasteners are needed immediately. Portable units are often designed to be modular, allowing them to be easily transported and quickly assembled at the point of use. These machines provide flexibility and convenience without sacrificing the quality or durability of the coatings.

Research into new coating materials continues to expand the capabilities of fastener coating machines. Innovations like graphene-based coatings, nanostructured layers, and ceramic-polymer composites offer exciting possibilities for enhancing the performance of fasteners. These materials provide exceptional properties, such as ultra-high strength, chemical resistance, and low thermal conductivity, making them ideal for cutting-edge applications in fields like renewable energy, aerospace, and medical devices. Coating machines capable of handling these advanced materials are likely to become a competitive advantage for manufacturers aiming to stay at the forefront of their industries.

In conclusion, fastener coating machines are rapidly advancing to meet the growing demands for precision, performance, and sustainability. By incorporating cutting-edge technologies, such as hybrid systems, smart automation, and eco-friendly processes, these machines are transforming the way fasteners are manufactured and prepared for diverse applications. As industries continue to push the boundaries of what coated fasteners can achieve, the development of innovative coating machines will remain a driving force in modern manufacturing.

The future of fastener coating machines is closely tied to the broader trends of digitalization, sustainability, and material innovation. As manufacturers increasingly adopt Industry 4.0 principles, the integration of artificial intelligence (AI) and machine learning (ML) in fastener coating processes is set to revolutionize the industry. These technologies enable machines to analyze vast amounts of operational data in real time, identifying patterns and making autonomous adjustments to optimize performance. For example, an AI-enabled coating machine could dynamically adjust spray angles, fluid flow rates, or curing temperatures to compensate for environmental changes or variations in fastener geometry, ensuring consistent quality without human intervention.

Predictive maintenance is another significant benefit of AI and IoT integration in fastener coating machines. Sensors embedded throughout the equipment monitor critical components, such as motors, bearings, and nozzles, for signs of wear or potential failure. This data is analyzed to predict when maintenance is required, allowing operators to schedule repairs proactively, minimizing unplanned downtime and extending the machine’s operational life. Such advancements are particularly valuable in high-volume production environments, where even brief interruptions can lead to significant losses.

Sustainability will remain a central focus in the evolution of fastener coating machines. Beyond the adoption of low-VOC coatings and waste-reduction systems, there is increasing interest in energy-neutral or carbon-neutral production lines. Machines powered by renewable energy sources, such as solar panels or wind turbines, are being explored to reduce the carbon footprint of coating operations. Additionally, advancements in energy storage and efficient curing technologies, such as LED-based UV curing, are making it feasible for manufacturers to transition toward greener production practices.

Advanced simulation and modeling tools are further enhancing the design and performance of fastener coating machines. Digital twins, virtual replicas of the physical machines, enable manufacturers to simulate coating processes under various conditions, optimizing settings for maximum efficiency and minimal waste. These tools also facilitate the design of custom machines tailored to specific industrial needs, reducing development time and ensuring that the final product meets exact specifications. As simulation technologies become more sophisticated, they are expected to play an even greater role in driving innovation and improving the overall efficiency of coating systems.

Another area poised for growth is the integration of coating machines with broader manufacturing ecosystems. In smart factories, coating machines will increasingly function as interconnected nodes within a larger network, communicating seamlessly with other equipment such as machining centers, assembly lines, and quality control systems. This integration allows for end-to-end traceability and greater operational coordination. For instance, if a batch of fasteners requires rework or adjustments during coating, the system can automatically relay this information to downstream processes, ensuring that production schedules are maintained without compromising quality.

Emerging applications are also driving the need for specialized coating solutions and machines. In the electric vehicle (EV) industry, for example, fasteners are exposed to unique challenges such as high voltages, thermal cycling, and electromagnetic interference. Coating machines are being developed to apply advanced materials that meet these requirements, such as dielectric coatings for electrical insulation or thermal barrier coatings for heat resistance. Similarly, the renewable energy sector demands fasteners with superior corrosion resistance for use in wind turbines, solar panel installations, and offshore platforms, spurring the development of machines capable of applying ultra-durable coatings.

Globalization and the increasing complexity of supply chains are influencing the design of fastener coating machines as well. With manufacturers operating across multiple locations and catering to diverse markets, there is a growing demand for machines that can easily adapt to different regional standards and regulations. Machines with multi-language interfaces, customizable software, and modular designs that can be upgraded or reconfigured are becoming more prevalent. Remote diagnostics and support capabilities are also essential, allowing manufacturers to provide technical assistance and resolve issues quickly, regardless of the machine’s physical location.

In summary, the trajectory of fastener coating machines is defined by a convergence of technological, environmental, and industrial trends. From AI-driven process optimization and predictive maintenance to the adoption of sustainable practices and the development of cutting-edge materials, these machines are evolving to meet the demands of a rapidly changing manufacturing landscape. As industries continue to innovate and push the boundaries of performance, fastener coating machines will remain at the forefront, enabling the production of components that are not only functional and durable but also sustainable and adaptable to future challenges.

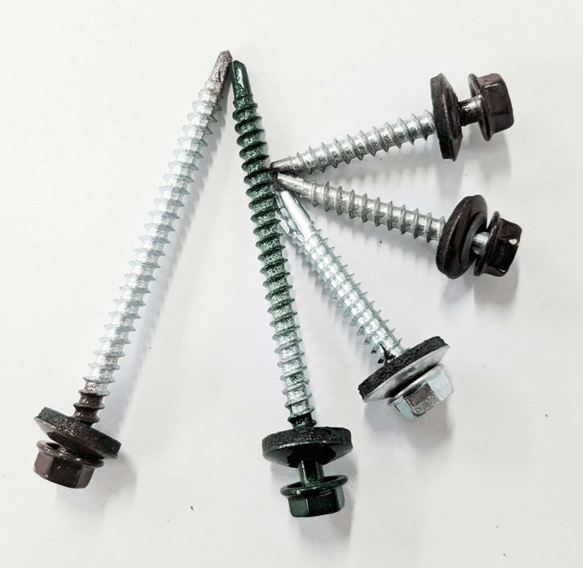

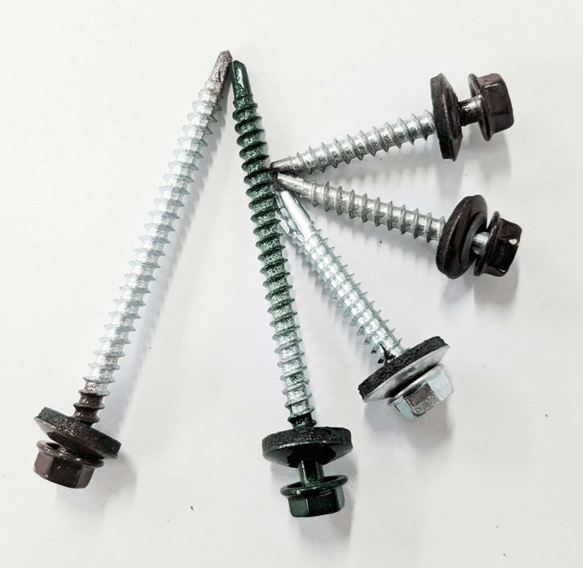

Painting Stainless Steel Screw Heads

Painting stainless steel screw heads involves a specialized process to ensure that the paint adheres properly, provides a durable finish, and maintains the aesthetic or functional requirements for the application. Stainless steel, known for its corrosion resistance and smooth surface, can be challenging to paint because its surface tends to resist adhesion. As a result, proper surface preparation, material selection, and application techniques are critical to achieving a high-quality, long-lasting finish on stainless steel screw heads.

The process begins with thorough cleaning and surface preparation. Stainless steel screw heads are typically treated to remove contaminants such as grease, oil, dirt, or oxidation that can interfere with paint adhesion. This step may involve using solvents, degreasers, or ultrasonic cleaning methods to ensure the surface is completely clean. After cleaning, abrasive methods such as sanding, bead blasting, or the application of a chemical etching primer may be used to roughen the surface slightly, creating a texture that allows the paint to adhere more effectively.

Priming is a crucial step when painting stainless steel screw heads. A high-quality primer specifically designed for metal surfaces, especially stainless steel, is applied to enhance paint adhesion and provide a durable base layer. Epoxy-based primers or self-etching primers are commonly used for this purpose, as they chemically bond to the stainless steel surface and provide excellent resistance to corrosion. The primer is applied in a thin, even coat to ensure complete coverage without creating an excessively thick layer that could affect the screw’s functionality.

Once the primer has cured, the paint is applied to the screw heads. The choice of paint depends on the desired finish and the environmental conditions the screws will face. For decorative purposes, enamel or acrylic paints may be used to provide a smooth, glossy finish. For industrial or outdoor applications, polyurethane or powder coatings are often preferred due to their superior durability, chemical resistance, and UV stability. Paint can be applied using various techniques, such as spraying, dipping, or brushing, depending on the production volume and the level of precision required. Automated systems with robotic arms or rotary fixtures are commonly used for high-volume production to ensure consistent coverage across all screw heads.

To achieve uniform color and finish, stainless steel screw heads are typically painted in controlled environments, such as paint booths or chambers with regulated temperature, humidity, and air circulation. This prevents dust, debris, or temperature fluctuations from compromising the paint’s quality. Multiple coats of paint may be applied to achieve the desired color depth and durability, with each coat allowed to dry or cure fully before the next is applied. Between coats, light sanding may be performed to remove imperfections and improve the adhesion of subsequent layers.

Curing is a critical part of the process, particularly for paints that require heat or UV exposure to achieve full hardness and durability. Curing ovens or UV curing systems are often used to expedite this step, ensuring that the painted screw heads achieve their maximum resistance to wear, impact, and environmental factors. Proper curing also enhances the paint’s adhesion to the stainless steel surface, reducing the likelihood of peeling or chipping over time.

Quality control measures are essential throughout the painting process. Inspections are conducted to ensure that the paint is evenly applied, adheres properly, and meets the specified color and gloss levels. Coating thickness is measured using tools such as micrometers or ultrasonic gauges to ensure compliance with standards. Additionally, tests for adhesion, impact resistance, and corrosion resistance may be performed to verify the durability of the painted finish.

For applications where aesthetics are critical, such as architectural projects or consumer products, painted stainless steel screw heads are often color-matched to blend seamlessly with surrounding materials. Custom color options are achieved using advanced color-matching technology and precision mixing of paints. In some cases, special effects, such as metallic finishes or textures, may be added to enhance the visual appeal of the screw heads.

Sustainability is an emerging consideration in the painting of stainless steel screw heads. The use of low-VOC paints and water-based coatings is gaining popularity due to their reduced environmental impact and improved workplace safety. Recycling systems for paint overspray and waste are also being implemented to minimize material wastage and environmental contamination.

In conclusion, painting stainless steel screw heads is a meticulous process that requires attention to detail and the use of advanced materials and techniques. Proper surface preparation, priming, and curing are essential to achieving a durable and visually appealing finish. As technology and materials continue to evolve, the process is becoming more efficient, sustainable, and capable of meeting the diverse needs of industries ranging from construction and automotive to consumer products and electronics. With the right approach, painted stainless steel screw heads can combine functionality with aesthetics, providing a high-performance solution for a wide range of applications.

The process of painting stainless steel screw heads is evolving in response to advancements in technology, the growing demand for customization, and the increasing focus on durability and sustainability. Modern techniques are pushing the boundaries of what can be achieved, both in terms of the functional and aesthetic qualities of the finished product.

One notable trend is the use of automated systems for painting screw heads, particularly in high-volume production environments. Automated robotic arms, equipped with precision nozzles, can apply paint consistently and accurately, even to small or intricately shaped screw heads. These systems can be programmed to apply multiple layers of primer, paint, or topcoat in a single process, reducing production times while ensuring uniformity across large batches. Advanced automation also allows for the application of intricate patterns or designs, offering manufacturers greater flexibility in customizing the appearance of screw heads.

Electrostatic painting is another advanced method gaining traction for painting stainless steel screw heads. This technique involves charging the paint particles with an electrical charge and grounding the stainless steel screw heads. The electrostatic attraction ensures that the paint adheres evenly to the surface, even in hard-to-reach areas. This method not only reduces paint waste but also improves efficiency by minimizing overspray. Electrostatic painting is particularly effective for achieving a smooth, high-quality finish on stainless steel surfaces.

For applications where extreme durability is required, powder coating has become a preferred method for painting stainless steel screw heads. Powder coating involves applying a dry powder to the screw heads, which is then melted and cured in an oven to form a hard, protective layer. This method offers exceptional resistance to corrosion, abrasion, and UV exposure, making it ideal for outdoor or high-stress environments. Powder coating also allows for a wide range of colors and finishes, including matte, gloss, and metallic effects, giving manufacturers the ability to tailor the appearance to specific requirements.

Nanotechnology is also influencing the field of painting stainless steel screw heads. Nanocoatings, which involve the application of ultra-thin layers of materials at the molecular level, are being developed to provide enhanced performance characteristics. For example, nanocoatings can offer self-cleaning properties, improved resistance to chemicals, or even antimicrobial features. These coatings are often applied using advanced spraying or dipping techniques, ensuring a uniform and precise application. While still emerging, nanotechnology holds significant potential for revolutionizing how screw heads are painted and protected.

Environmental sustainability remains a major driver of innovation in painting processes. Manufacturers are adopting water-based paints and coatings with minimal environmental impact, reducing the use of hazardous solvents and lowering VOC emissions. High-efficiency filtration and recovery systems are also being integrated into paint booths to capture and recycle overspray, further minimizing waste. Additionally, many manufacturers are transitioning to energy-efficient curing systems, such as LED-based UV curing, which consume less energy and generate less heat compared to traditional curing ovens.

Customization and personalization are becoming increasingly important, especially in consumer-facing industries. Painted stainless steel screw heads are now available in a vast array of colors, textures, and finishes to match specific design preferences. Color-matching technology allows manufacturers to replicate exact hues, enabling screw heads to blend seamlessly with surrounding materials or serve as a visual highlight in a product design. Textured or patterned finishes, such as brushed or hammered effects, are also gaining popularity, adding a distinctive aesthetic to otherwise utilitarian components.

Surface preparation techniques are evolving to accommodate the growing variety of stainless steel screw head designs and applications. Laser etching is being explored as a method to create micro-textures on the screw head surface, enhancing paint adhesion without the need for abrasive methods. This technique is precise and non-invasive, preserving the structural integrity of the screw while ensuring optimal paint performance. Innovations like plasma treatment are also being utilized to activate the stainless steel surface, improving paint bonding and reducing the need for chemical primers.

Quality assurance processes are becoming increasingly sophisticated, leveraging digital technologies to ensure consistency and reliability. Automated inspection systems, equipped with high-resolution cameras and machine vision algorithms, can detect even minute defects in the paint application, such as pinholes, uneven thickness, or discoloration. These systems provide real-time feedback, allowing operators to make adjustments immediately and reducing the likelihood of defective products reaching the end user.

In conclusion, the painting of stainless steel screw heads is a rapidly advancing field that combines traditional craftsmanship with cutting-edge technology. From automated systems and electrostatic painting to nanotechnology and sustainable practices, the methods used to enhance the appearance and functionality of these components are becoming more efficient, precise, and versatile. As industries continue to demand higher performance and greater customization, the innovations in painting techniques will ensure that stainless steel screw heads not only meet but exceed expectations in terms of durability, aesthetics, and environmental responsibility.

The advancements in painting stainless steel screw heads also extend to improving long-term durability and performance under extreme conditions. Innovations in high-performance coatings are enabling screws to withstand harsh environments, such as exposure to chemicals, salt spray, or high temperatures, without compromising the integrity of the paint or the underlying material. These developments are particularly important for industries such as marine, aerospace, and construction, where screw heads must endure challenging conditions for extended periods.

One cutting-edge development is the use of ceramic-infused coatings, which combine the toughness of ceramics with the flexibility and adhesion of traditional paints. These coatings provide exceptional resistance to abrasion and thermal stress, making them ideal for screws used in high-temperature environments or where mechanical wear is a concern. The ceramic particles within the coating also enhance UV resistance, preventing discoloration or degradation caused by prolonged exposure to sunlight.

For environments where moisture or corrosive substances are prevalent, hybrid coatings that combine multiple protective layers are becoming increasingly popular. These systems often involve a base layer for corrosion resistance, a mid-layer for mechanical strength, and a topcoat for aesthetic appeal or specific functional properties. For example, a stainless steel screw head used in an offshore application might feature an epoxy primer, a polyurethane middle layer, and a fluoropolymer topcoat to maximize protection and durability.

Advancements in low-friction coatings are also gaining attention for applications where screw heads are subjected to repeated torqueing or movement. These coatings, often incorporating PTFE (polytetrafluoroethylene) or similar materials, reduce friction between the screw and the surrounding material, preventing paint chipping or flaking during installation or removal. Such coatings are particularly valuable in assembly-line production environments, where screws are often installed using automated tools that apply consistent torque.

Smart coatings are an emerging area of interest, integrating functionality beyond traditional paint systems. For instance, some coatings now incorporate embedded sensors or conductive particles that allow for real-time monitoring of the screw’s environment or structural integrity. These coatings can provide data on factors such as temperature, humidity, or mechanical strain, enabling predictive maintenance or alerting operators to potential issues before they become critical. While still in the experimental stages, smart coatings have the potential to revolutionize how painted fasteners are utilized and maintained in advanced industrial applications.

In terms of efficiency, continuous production lines are streamlining the painting of stainless steel screw heads at scale. Modern lines often combine surface preparation, priming, painting, and curing in a single, automated process, reducing the time and labor required while maintaining consistent quality. These systems can be further enhanced with conveyorized solutions that transport screw heads through each stage seamlessly, allowing for high-volume production without interruptions or bottlenecks.

Furthermore, sustainability and environmental compliance are becoming non-negotiable priorities for manufacturers. Governments and industry bodies are imposing stricter regulations on the use of hazardous materials and the environmental impact of manufacturing processes. To address these requirements, many companies are transitioning to waterborne coatings, powder coatings, or high-solid paints, which reduce solvent emissions and material waste. Additionally, manufacturers are investing in closed-loop systems that recycle solvents, recover overspray, and treat wastewater, minimizing the ecological footprint of the painting process.

Customer demand for unique finishes and branding opportunities has also driven innovation in the painting of stainless steel screw heads. Decorative finishes, such as metallic, pearlescent, or anodized-look coatings, allow screw heads to complement the design aesthetics of consumer products. Custom logos, patterns, or text can also be applied using laser engraving or specialized printing techniques on top of the painted surface, adding a layer of personalization or branding that enhances the product’s appeal.

Emerging technologies like 3D printing are beginning to influence the painting process as well. Custom fixtures and masking solutions, created using 3D printing, allow for precise and repeatable application of paint to complex or non-standard screw head geometries. These innovations enable manufacturers to explore creative designs and functionalities that were previously difficult or impossible to achieve using traditional methods.

In conclusion, the field of painting stainless steel screw heads continues to evolve with the adoption of advanced materials, cutting-edge technologies, and sustainable practices. From ceramic-infused and hybrid coatings to smart functionalities and decorative finishes, the possibilities are expanding, allowing manufacturers to meet a diverse range of functional and aesthetic requirements. These innovations ensure that painted stainless steel screw heads not only serve their practical purposes but also contribute to the overall value, performance, and appeal of the products and systems they support.

As the field of painting stainless steel screw heads continues to evolve, another significant development is the integration of advanced surface treatments that further enhance the performance and durability of the painted finish. These treatments go beyond traditional cleaning and roughening methods, providing additional layers of protection and improving the bond between the paint and the metal surface.

One such treatment is the application of chromate conversion coatings or passivation processes. These treatments are typically used to enhance the corrosion resistance of stainless steel before painting. Chromate coatings create a thin, protective layer that prevents corrosion while providing excellent adhesion for the paint. Passivation, on the other hand, involves immersing the stainless steel screw heads in an acid solution to remove free iron and enhance the formation of a protective oxide layer. While these treatments are not a replacement for painting, they provide an additional layer of protection that improves the longevity of both the screw and its coating.

Anodizing is another advanced treatment gaining traction, particularly for aluminum screws or other metals with similar properties to stainless steel. Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of the metal, improving its resistance to corrosion and wear. Although it is more commonly used for aluminum, anodizing is being explored for stainless steel as well, especially in environments where aesthetic appeal and corrosion resistance are paramount. The anodized surface can then be painted or coated for added durability, creating a highly resilient finish.

In addition to surface treatments, advancements in coating application methods are continually improving the quality and efficiency of painting stainless steel screw heads. Nano-coating technologies, for instance, enable the application of ultra-thin, highly functional layers that not only protect the screw heads from wear and corrosion but also offer properties such as anti-fingerprint, self-cleaning, or water-repellent surfaces. These coatings use nanomaterials to create a surface that repels dirt, moisture, and oils, making the screw heads easier to maintain and prolonging the lifespan of both the paint and the screw itself.

Electrophoretic deposition (EPD), a process often used for coating complex or intricate parts, is also making its way into fastener coating applications. EPD involves using an electric field to deposit a paint or resin onto the stainless steel screw heads. This method ensures uniform coverage, even on parts with complex geometries, such as threaded surfaces. The advantage of EPD is its ability to coat hard-to-reach areas that may be missed with traditional spray painting techniques, ensuring comprehensive protection for all exposed surfaces.

The rise of robotic automation is further pushing the boundaries of painting stainless steel screw heads. Automated systems are now being used not only for coating application but also for handling and positioning screws during the process. This automation ensures consistency and accuracy in every part of the painting cycle, from surface preparation to curing, leading to fewer defects and higher throughput. Moreover, robots can operate in hazardous environments, improving safety by minimizing human exposure to chemicals, fumes, and other risks.

As part of the push toward greater efficiency and sustainability, integrated paint recovery systems are becoming more common in fastener coating lines. These systems capture overspray and excess paint during application and allow for the paint to be filtered, purified, and reused, reducing material waste and minimizing the environmental impact of the process. In addition, the use of closed-loop systems in curing and drying ovens ensures that energy consumption is minimized by recapturing heat and reducing the need for excessive power input. These energy-efficient systems contribute significantly to reducing the carbon footprint of the coating process, aligning with the industry’s sustainability goals.

In industries where hygiene and cleanliness are critical, such as food processing, medical, and pharmaceutical applications, special coatings are being developed to meet strict health and safety standards. These coatings are not only durable but also non-toxic, antimicrobial, and resistant to the accumulation of bacteria and other contaminants. In these applications, stainless steel screw heads need coatings that can withstand frequent cleaning with harsh chemicals and maintain their integrity without degrading or losing their protective properties.

With consumer demand for more customized solutions, manufacturers are increasingly offering painted stainless steel screw heads in a variety of finishes, textures, and colors. For example, anodized finishes, matte coatings, and brushed textures are becoming popular for products that require both functionality and aesthetic appeal. The ability to match specific color schemes, such as custom hues or metallic finishes, is particularly relevant for high-end consumer products and architectural applications where the appearance of the fasteners is just as important as their performance.

The growing trend of 3D printing in the fastener industry is also influencing the painting process. 3D printed stainless steel screw heads often require specialized surface treatments and painting processes to ensure the final product meets both aesthetic and functional standards. Advanced 3D printing techniques can produce complex geometries and intricate designs that are not possible with traditional manufacturing methods, but they also introduce challenges in ensuring consistent surface quality. As such, a combination of 3D printing and innovative painting techniques is enabling manufacturers to produce fasteners that are both highly customized and of superior quality.

In conclusion, the painting of stainless steel screw heads is continuously evolving, driven by innovations in surface treatments, coating technologies, application methods, and sustainability practices. As industries continue to demand more durable, aesthetic, and environmentally responsible solutions, manufacturers are adopting advanced technologies such as nanocoatings, robotic automation, and energy-efficient curing systems to meet these needs. With the growing emphasis on customization and performance, painted stainless steel screw heads are poised to become an integral component of a wide range of industries, ensuring that they not only serve their practical functions but also contribute to the overall quality and longevity of the products they help assemble.

As the painting process for stainless steel screw heads continues to evolve, the influence of advanced research and development is playing an increasingly significant role in driving future innovations. Researchers and manufacturers are exploring new ways to further enhance the properties of both the coatings and the fasteners themselves, with a strong emphasis on multifunctionality, longer service life, and eco-friendly solutions. These innovations promise to meet the growing demands of industries that require high performance in increasingly demanding environments.

One area of significant exploration is the development of self-healing coatings for stainless steel screw heads. These coatings contain embedded microcapsules that release healing agents when the coating is damaged, such as by scratches or abrasions. The healing agents then repair the damaged area, restoring the protective layer and preventing the corrosion that typically follows such damage. This concept has immense potential, particularly for screws used in harsh environments where mechanical wear and tear are common. Self-healing coatings could significantly extend the lifespan of painted fasteners, reducing maintenance and replacement costs while improving the overall reliability of the systems in which they are used.

Another exciting direction in fastener coating technology is the integration of antifouling and anti-corrosion coatings. These coatings, often used in marine or offshore environments, are specifically designed to resist the build-up of barnacles, algae, or other biological materials, as well as prevent rust and corrosion. While antifouling coatings are common for boat hulls and underwater structures, their application to stainless steel screw heads could be a game-changer for industries working in highly corrosive or biologically active environments, such as marine, offshore oil rigs, or water treatment facilities. These coatings provide a dual function—preventing corrosion and reducing maintenance needs by limiting the accumulation of biological growth on the screw heads.

At the same time, high-temperature coatings designed to withstand extreme heat conditions are evolving. In industries like aerospace, automotive, and heavy manufacturing, stainless steel screws are often exposed to high temperatures that can cause conventional coatings to degrade or fail. New heat-resistant coatings, often incorporating ceramic or graphene materials, are being developed to provide superior protection at elevated temperatures, without compromising the mechanical properties of the screw. These advanced coatings not only protect against high heat but also help reduce the risk of oxidation, ensuring that screws maintain their strength and integrity even under extreme conditions.

On the eco-friendly front, there’s a growing emphasis on reducing the environmental impact of the painting process itself. In addition to the use of water-based paints and low-VOC formulations, bio-based coatings are emerging as a sustainable alternative to traditional petrochemical-based products. These bio-based coatings are made from renewable plant materials, such as soy or algae, and offer similar performance characteristics as their synthetic counterparts. The adoption of these coatings is part of a broader movement toward reducing the carbon footprint of manufacturing processes and creating products that are both functional and environmentally responsible.

Furthermore, the trend toward zero-waste manufacturing is gaining momentum in the fastener coating industry. This involves the implementation of technologies that eliminate or drastically reduce waste generated during the painting process. For example, closed-loop systems that recycle paint overspray and reduce material waste are becoming more prevalent. In addition, advancements in curing systems, such as low-energy LED curing, are enabling manufacturers to lower energy consumption and reduce emissions, further contributing to the sustainability of the painting process.

Automation is also playing an essential role in pushing the boundaries of quality control and consistency. Automated systems are now not only applying the coatings but also performing detailed inspections to ensure that every screw head meets stringent quality standards. These systems are equipped with advanced vision technologies and sensors that can detect even minute imperfections in the paint coating, such as air bubbles, imperfections, or inconsistencies in the color. This ensures that only flawless products proceed to the next stages of production, enhancing the overall quality and reliability of the painted screw heads. The integration of machine learning and artificial intelligence (AI) in these automated systems enables continuous improvement by analyzing patterns and optimizing coating application based on real-time data.

In addition to quality control, data analytics is playing a key role in optimizing the entire painting process. Manufacturers are increasingly collecting and analyzing data from each stage of the painting process—surface preparation, priming, painting, curing, and inspection. By using advanced analytics tools, manufacturers can identify bottlenecks, minimize inefficiencies, and even predict future maintenance needs for coating machines. This data-driven approach helps streamline production, reduce downtime, and ultimately lower costs while improving the consistency and quality of the final product.

The customization trend is also extending beyond just the color or finish of the screw heads. Personalized features, such as customized patterns or logos, are becoming more popular, especially in consumer-facing industries. This is particularly relevant in products like electronics, furniture, and high-end appliances, where screw heads need to match the design language of the product. Through techniques like laser engraving, screen printing, or digital printing, manufacturers can add intricate designs or logos to the painted screw heads, further enhancing their appeal and providing branding opportunities for companies.

Finally, the demand for smart fasteners is beginning to influence the coating process. Smart fasteners are equipped with embedded sensors that can detect changes in temperature, strain, or environmental conditions. These sensors relay information to a central system, allowing operators to monitor the integrity and performance of the screws in real-time. When paired with advanced coatings, these smart fasteners can offer a combination of durability, functionality, and real-time monitoring, making them ideal for critical applications in aerospace, automotive, and industrial sectors.

In conclusion, the painting of stainless steel screw heads is undergoing a remarkable transformation. As industries continue to push the boundaries of performance, customization, and sustainability, manufacturers are exploring new materials, technologies, and processes that will redefine the role of painted fasteners in modern products. With advancements in multifunctional coatings, automation, sustainability, and smart technologies, painted stainless steel screw heads are poised to become even more integral to the success of a wide range of industries. The ongoing innovations will not only enhance the aesthetic appeal and durability of the screws but will also contribute to improved performance, environmental responsibility, and overall efficiency in manufacturing processes.

Bolt Coating Machine

The bolt coating machine plays a pivotal role in the manufacturing and finishing of bolts, offering a wide range of applications to ensure these fasteners meet specific performance, aesthetic, and environmental standards. This machinery is designed to apply coatings to bolts efficiently, ensuring the desired properties such as corrosion resistance, durability, aesthetics, and specialized functionalities. Over the years, bolt coating machines have undergone significant advancements, enabling manufacturers to meet the ever-increasing demands for high-quality, customizable, and sustainable coating solutions for bolts used in various industries, including automotive, construction, marine, aerospace, and oil and gas.

Machine Design and Functionality

Bolt coating machines are typically designed with a focus on precision, efficiency, and flexibility, allowing for the application of various types of coatings depending on the specific requirements of the bolts. These machines are often modular, providing manufacturers with the ability to customize the system for different types of coatings and bolt sizes. The machine typically includes several key components, such as a pre-treatment system, coating application system, curing system, and inspection stations.

- Pre-Treatment System: Before the bolts are coated, they are often subjected to a pre-treatment process that prepares their surface for optimal paint adhesion. This may involve cleaning, degreasing, or surface etching to remove contaminants, rust, or oxide layers. Pre-treatment methods can include shot blasting, sandblasting, acid cleaning, or plasma treatment, all of which improve the bond between the coating and the bolt surface.

- Coating Application System: The coating application process is where the primary innovation in bolt coating machinery lies. Depending on the type of coating used, different techniques may be employed. Some common methods include:

- Spray Coating: One of the most widely used techniques for bolt coating, spray coating involves the use of automated spray nozzles to apply a liquid or powder coating to the surface of the bolts. Spray systems can be fine-tuned to deliver uniform coverage, ensuring consistent thickness and a high-quality finish.

- Electrostatic Powder Coating: In this process, powder particles are charged electrostatically and attracted to the grounded bolt surface. The charged particles adhere to the bolt, and the part is then cured at a high temperature, resulting in a durable, hard coating.

- Dipping or Immersion Coating: For certain coatings like galvanizing or dip coating, bolts are immersed in a liquid coating solution, such as molten zinc or a polymer. The bolts are then removed, and excess coating is allowed to drip off before curing.

- Roller Coating: In cases where bolts have a consistent and relatively simple geometry, roller coating machines use rotating rollers to apply an even layer of coating.

- Curing System: After the coating is applied, it must be cured to bond it to the bolt’s surface and ensure its functionality. Different coatings require different curing processes, such as heat curing (in an oven), UV curing (for specific UV-sensitive coatings), or electron beam curing. Curing systems can vary in terms of the temperature, time, and energy required, depending on the coating material used.

- Inspection Stations: To ensure the coating is uniform and free from defects, inspection systems are integrated into the machine setup. These systems utilize vision cameras, laser scanners, and other sensors to inspect the bolts for flaws such as irregular coating thickness, bubbles, or adhesion issues. This allows manufacturers to ensure that only flawless products move on to the next stage of production.

Advanced Coating Technologies

In recent years, there have been significant improvements in the types of coatings that bolt coating machines can apply. The demand for longer-lasting, high-performance coatings has driven innovation in both the materials used and the application techniques. Some of the most advanced technologies include:

- Nano-coatings: Nano-coatings are ultra-thin layers applied to bolts that offer extraordinary properties, such as enhanced corrosion resistance, reduced friction, and self-cleaning abilities. These coatings are typically applied using highly precise deposition techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD). The nano-coating process is highly specialized and requires specialized machinery for optimal results, providing manufacturers with bolts that last longer and require less maintenance.

- Ceramic and Graphene Coatings: Ceramic-based coatings are gaining popularity for bolts exposed to extreme wear, high temperatures, or corrosive environments. These coatings offer significant protection against thermal shock, high friction, and corrosion. Similarly, graphene coatings—comprising a single layer of carbon atoms—are increasingly used due to their incredible strength, high thermal conductivity, and flexibility. These coatings are often applied using cutting-edge techniques such as spray deposition or PVD, and they deliver exceptional protection for bolts used in high-stress environments.

- Anti-Corrosion Coatings: Zinc coatings (galvanization) and cadmium coatings are commonly used for bolts in outdoor or harsh environments. Bolt coating machines can automate the galvanization process, which involves dipping bolts into a molten zinc bath to create a protective layer. This process not only provides corrosion resistance but also offers an aesthetic finish with a shiny, silver appearance. Additionally, some advanced anti-corrosion coatings use zinc-aluminum alloys or epoxy-based coatings for enhanced performance.

- Lubricating Coatings: Dry-film lubricants are used to reduce friction and wear between bolts and the materials they fasten. These coatings are particularly useful in automotive, aerospace, and machinery applications, where bolts are subject to high torques and stresses. Coating machines designed for dry-film lubricants can apply these coatings in a highly controlled manner to ensure consistent thickness and performance.

- Flame Retardant and Heat-Resistant Coatings: For bolts used in extreme temperatures, flame-retardant coatings or heat-resistant coatings are essential. These coatings are typically applied via spray systems or dipping, followed by heat curing. They prevent the degradation of bolts under high-heat conditions, providing added protection in automotive engines, aerospace applications, and industrial machinery.

Automation and Efficiency Improvements

The advent of automation has had a profound impact on the performance of bolt coating machines. Automated systems are increasingly designed to operate continuously, reducing human intervention and ensuring high-speed production with consistent results. Machines can be programmed to handle different bolt sizes, coating types, and operational parameters, allowing for rapid changes between product runs and minimizing downtime.

Additionally, robotic arms are being used in coating machines for their precision in handling bolts, especially in more complex coating processes. These robotic systems can position bolts in spray booths, dip tanks, or curing stations with extreme accuracy, ensuring that every bolt receives uniform coverage and optimal curing.

Data integration and predictive maintenance are also improving operational efficiency. Bolt coating machines equipped with sensors and IoT (Internet of Things) capabilities can monitor performance in real time. This allows manufacturers to track key parameters such as coating thickness, curing temperature, and machine health. The data collected can be analyzed to optimize the coating process, predict maintenance needs, and even improve coating formulations for future runs.

Sustainability and Environmental Impact

As environmental concerns become more pronounced, bolt coating machines are evolving to meet sustainability requirements. Water-based coatings, which emit fewer volatile organic compounds (VOCs), are becoming more popular as an alternative to solvent-based coatings. Powder coating is another eco-friendly option, as it produces little to no waste and does not require solvents. Furthermore, closed-loop systems that capture and recycle overspray during the coating process are now standard in many bolt coating machines, reducing material waste and improving cost efficiency.

In addition, manufacturers are focusing on reducing energy consumption during the curing process. LED curing systems are more energy-efficient than traditional ovens, and they provide faster curing times, reducing production cycles and energy costs. The move toward sustainable production is not only improving environmental outcomes but also contributing to more cost-effective manufacturing.

Conclusion

The development of bolt coating machines has significantly advanced in recent years, driven by innovations in coating materials, automation, and sustainability. These machines are now capable of applying a wide range of coatings that improve the performance, durability, and aesthetic appeal of bolts, while also reducing environmental impact. With continued improvements in coating technologies and machine design, manufacturers can expect to see even more efficient, precise, and eco-friendly solutions that meet the evolving demands of industries that rely on high-quality, durable fasteners. Whether through the application of cutting-edge coatings like nanotechnology or robotic automation, bolt coating machines are poised to play an even more integral role in producing high-performance, long-lasting bolts for a variety of applications.

As the technology behind bolt coating machines continues to evolve, several additional trends and innovations are shaping the future of the industry. These advancements not only aim to enhance the capabilities of the coating machines themselves but also respond to growing demands for customization, flexibility, speed, and sustainability across industries.

Customization and Precision Coatings

One of the most notable developments in bolt coating technology is the increasing demand for customized coatings. Industries such as automotive, aerospace, and electronics require fasteners that are not only functional but also highly tailored to the specific needs of the application. For example, bolts used in the aerospace industry must adhere to strict aerospace standards for corrosion resistance, temperature endurance, and mechanical performance, while also potentially featuring custom finishes or color schemes for visual identification. Similarly, bolts used in luxury consumer products, like high-end electronics or custom furniture, often need coatings that offer both protection and an aesthetically pleasing appearance.

Bolt coating machines are becoming increasingly modular and adaptable, enabling manufacturers to quickly switch between different coating formulations and processes. This level of customization can be achieved through the use of programmable control systems and robotic automation, which allow for easy adjustments in the coating parameters, such as coating thickness, cure time, and type of finish. This flexibility is particularly useful in industries where production runs are shorter, and the demand for variety is higher.

In addition to basic surface protection, more specialized coatings are emerging, including anti-microbial or anti-fingerprint coatings. These coatings are gaining popularity in sectors where hygiene and cleanliness are critical, such as the medical device industry or food processing. The integration of specialized additives into the coatings not only provides protection against bacteria and viruses but also enhances the performance of bolts by ensuring that they remain free of marks or smudges, even after repeated handling or exposure to oils and grime.

Advanced Coating Materials and Techniques

The use of advanced materials for bolt coatings is a significant trend, as it enables bolts to meet the increasingly demanding performance standards of modern industries. For example, thermal spray coatings, which involve the application of molten or heated material to the bolt’s surface, are used to create coatings that are highly resistant to heat, wear, and corrosion. These coatings are particularly beneficial for bolts exposed to high temperatures or harsh environmental conditions, such as those used in the aerospace, power generation, and automotive industries.

PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) are advanced deposition techniques that are also becoming more prevalent in bolt coating machinery. These processes involve creating thin, durable, and highly specialized coatings by depositing vaporized materials onto the bolt surface in a vacuum. PVD coatings are often used for their hardness, wear resistance, and low friction properties, making them ideal for bolts that need to perform in high-stress applications, such as engine components or heavy machinery. CVD coatings are similarly used in environments that require high-temperature stability, corrosion resistance, and hardness.

Another emerging trend is the use of graphene-based coatings, which are known for their extraordinary strength, flexibility, and corrosion resistance. Graphene coatings are especially beneficial for bolts used in industries like automotive, aerospace, and marine, where bolts are exposed to intense stress, environmental challenges, and temperature fluctuations. These coatings can provide a significant performance boost, offering better mechanical properties, longer lifespan, and improved protection against corrosion, while also being lightweight and energy-efficient.

Incorporating Smart Technologies

In the future, the integration of smart technologies into bolt coating machines is likely to play a transformative role. Bolt coating machines are being equipped with sensor technologies and Internet of Things (IoT) capabilities, which allow manufacturers to monitor the entire coating process in real time. Sensors that measure factors such as humidity, temperature, coating thickness, and curing time can ensure that the coating process is as precise as possible. IoT connectivity can further enable manufacturers to track the machine’s performance remotely, collect data for analysis, and predict maintenance needs before problems arise.

Moreover, smart coatings that are embedded with sensors or conductive elements are gaining attention. These coatings can monitor the condition of the bolts over time by detecting changes in parameters like temperature, corrosion levels, or mechanical stress. This information is transmitted back to a central monitoring system, which can alert operators when bolts require maintenance or replacement. This real-time data collection can help improve the overall reliability of the fasteners, reduce downtime, and extend the life cycle of the components they are used in.

Improved Curing Systems and Energy Efficiency

The curing process is a critical part of the bolt coating cycle, as it ensures that the coating bonds properly and provides the necessary protective properties. With growing environmental concerns and the need for energy efficiency, new low-energy curing technologies are being introduced to reduce the energy consumption of curing systems. LED curing is a prime example of a more energy-efficient and faster method for curing coatings. LED lights produce significantly less heat compared to traditional UV lamps, leading to lower energy consumption and faster curing times. This can help reduce operating costs and increase the speed of production without compromising the quality of the coating.

In addition to LED curing, infrared curing and microwave curing are emerging as alternative methods that can offer faster processing times with minimal energy usage. These technologies heat the coating from the inside out, making them ideal for coatings that require deeper curing or those that may be sensitive to surface temperatures.

Manufacturers are also focusing on sustainable curing processes that do not rely on traditional, high-temperature ovens or large amounts of energy. Innovations in low-temperature curing processes have paved the way for faster, more energy-efficient coatings that can be processed at much lower temperatures. This is particularly relevant for coatings that are sensitive to heat, such as those used for plastic or composite bolts.

Robotics and Automation: Future Trends

The implementation of robotic systems in bolt coating machines is a game-changer, offering significant advantages in terms of speed, precision, and flexibility. Robotics are increasingly being used for bolt handling, surface preparation, coating application, and even inspection. Robotic arms can be programmed to handle multiple tasks without the need for human intervention, ensuring higher throughput and consistency across production batches. These systems can be integrated with vision systems to improve inspection quality, ensuring that bolts are coated to precise specifications without defects.

Additionally, automated inspection systems are becoming more sophisticated, incorporating technologies such as machine learning and AI to detect even the most minute coating defects. These automated systems can assess factors like coating thickness, color consistency, texture, and adhesion quality, providing real-time feedback to operators and minimizing the risk of faulty products reaching the next stage of production.

As automation continues to develop, the future of bolt coating machines will likely see fully integrated systems that connect the entire coating process—from pre-treatment to final inspection—into a streamlined workflow. This could include integrated feedback loops where data from one step in the process automatically adjusts parameters for subsequent steps, optimizing the entire coating cycle for efficiency, quality, and cost-effectiveness.

Sustainability and Waste Reduction

Sustainability remains a critical concern for manufacturers of bolt coating machines, and efforts to reduce waste and energy consumption are continually evolving. Closed-loop systems, which capture and reuse materials such as paint overspray, are becoming standard features in many modern coating machines. These systems help reduce the amount of material wasted during the coating process and ensure that resources are used more efficiently. The adoption of water-based paints and solvent-free coatings further contributes to reducing the environmental impact of bolt coating operations, aligning with global regulations and sustainability goals.

Moreover, the integration of energy-efficient technologies and the development of sustainable coating materials are further reducing the carbon footprint of the coating process. Companies are increasingly adopting recycling programs for coatings and other materials, helping to minimize their environmental impact and reduce operational costs.

Conclusion

The future of bolt coating machines is characterized by a convergence of innovation in coating materials, automation, energy efficiency, and sustainability. As manufacturers face the growing demands for high-performance, durable, and aesthetically appealing fasteners, bolt coating machines are adapting to meet these challenges by incorporating advanced technologies like robotics, smart coatings, and customization options. These advancements promise to improve not only the quality and efficiency of the coating process but also the sustainability and cost-effectiveness of bolt production. The ongoing evolution of bolt coating machines will play a key role in shaping industries that rely on high-quality fasteners, including automotive, aerospace, construction, and manufacturing, driving innovation and helping to create products that perform better and last longer.

As the future of bolt coating machines continues to evolve, several key factors will likely shape the direction of this technology. These include ongoing innovations in materials science, more sophisticated automation, an increased focus on sustainability, and the adoption of advanced digital technologies. Each of these developments will not only enhance the coating process itself but also allow manufacturers to meet the growing expectations for faster production cycles, lower environmental impact, and improved product quality.

Advanced Material Development and Coating Performance

The future of bolt coating is deeply tied to advancements in materials science. As industries push for faster, lighter, and more durable components, coating materials are being designed to meet more stringent requirements. Hybrid coatings, which combine the benefits of multiple coating materials, are gaining attention. For example, coatings that combine the corrosion resistance of zinc with the wear resistance of ceramic materials can help ensure that bolts maintain their structural integrity in challenging environments, such as marine or offshore applications. These hybrid materials are often created through multi-layer deposition techniques or the inclusion of functional additives in the base coating.

Additionally, self-healing coatings are an exciting development in the field of bolt coating technology. These coatings are designed to automatically repair themselves when they are damaged by external forces, such as scratches or impacts. This self-healing capability is achieved through the incorporation of microcapsules containing healing agents, which are released when the coating is compromised. This technology can extend the lifespan of bolts by preventing corrosion from spreading and reducing the need for frequent maintenance or replacement. Although still in its early stages, self-healing coatings could become a game-changer for applications where bolt longevity is critical, such as in the aerospace, defense, and automotive sectors.

Smart Manufacturing and IoT Integration

The integration of smart manufacturing principles into bolt coating machines will continue to increase the efficiency and precision of the coating process. By incorporating IoT (Internet of Things) technologies, bolt coating machines will be able to communicate with each other and with central control systems in real-time. This communication can lead to more accurate monitoring of every aspect of the coating process, from pre-treatment through to curing and inspection.

Data analytics will play a crucial role in this process, providing manufacturers with detailed insights into the performance of each machine and the quality of the finished product. For example, data gathered during production could be used to identify trends or patterns, enabling predictive maintenance that can prevent unexpected breakdowns or malfunctions. This approach not only helps reduce downtime but also optimizes the overall efficiency of the coating process, allowing manufacturers to adjust settings and processes dynamically to meet changing demands or quality requirements.

With the help of artificial intelligence (AI) and machine learning, bolt coating systems can be trained to detect even the slightest imperfections or inconsistencies in the coating. These AI-driven systems can analyze visual inspection data to identify potential defects faster and more accurately than human inspectors, ensuring that only high-quality bolts make it through the production line.

Customization for Niche Markets and Specialized Applications