Gas powder coating oven is used to cure powder coatings onto metal surfaces. They use natural gas or propane to generate heat, and they can typically reach temperatures of up to 400 degrees Fahrenheit.

Gas powder coating ovens are more energy-efficient than electric powder coating ovens, but they do produce emissions. It is important to properly ventilate the work area to remove these emissions.

Gas powder coating ovens are typically equipped with a number of safety features, including:

- Emergency stop button

- Overheating protection

- Fire suppression system

- Ventilation system

- Interlocking doors

These safety features help to protect workers, equipment, and the environment from potential hazards.

Safety guidelines for operating a gas powder coating oven:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, a respirator, and long sleeves and pants.

- Make sure the oven is properly ventilated to remove fumes and dust.

- Ground the oven to prevent electrical shock.

- Do not overload the oven.

- Inspect the oven regularly for damage or wear and tear.

- Have a fire extinguisher nearby.

Additional safety tips:

- Never operate a gas powder coating oven in an enclosed space.

- Keep flammable materials away from the oven.

- Be aware of the signs of a fire, such as smoke, heat, and flames. If you see or smell any of these signs, evacuate the area and call the fire department.

- Train your employees on the safe operation of the oven.

By following these safety guidelines, you can help to prevent accidents and injuries.

Gas Powder Coating Oven

Gas powder coating ovens typically use gas as a fuel source for the heating process in powder coating applications. Powder coating is a method of applying a protective and decorative finish to a wide range of materials, including metals and certain plastics.

Here’s a breakdown of how a gas powder coating oven might work:

- Preparation of the Object: Before powder coating, the object to be coated is cleaned and prepared. This often involves removing any existing coatings, oils, or contaminants.

- Application of Powder: The powder coating material is applied to the object electrostatically. This creates a uniform coating on the surface.

- Curing Process in the Oven: After the powder is applied, the object is moved to the curing oven. This is where the gas heating system comes into play. Gas-fired ovens are commonly used for their efficiency and cost-effectiveness.

- Heating and Curing: The oven is heated using gas burners. The heat causes the powder to melt and flow into a uniform coating. The curing process typically involves maintaining a specific temperature for a set period, allowing the coating to chemically cross-link and form a durable finish.

- Cooling: After the curing process is complete, the object is allowed to cool. The finished product is a durable, high-quality coating that is resistant to various environmental factors.

Gas ovens are popular in powder coating applications due to their ability to provide consistent and controlled heating. They are also relatively cost-effective compared to some alternative heating methods.

Gas oven:

A gas oven is a type of powder coating oven that uses natural gas or propane as a fuel source to heat the curing chamber. Gas ovens are typically more energy-efficient than electric ovens, and they can heat up more quickly. However, gas ovens can also produce more emissions, so it is important to ensure that they are properly ventilated.

Convection oven:

A convection oven is a type of gas powder coating oven that uses fans to circulate hot air throughout the curing chamber. This helps to ensure that the temperature is uniform throughout the chamber, which is important for curing the powder coating evenly. Convection ovens are typically more efficient than radiant ovens, and they can also cure parts more quickly.

Radiant oven:

A radiant oven is a type of gas powder coating oven that uses infrared radiation to heat the curing chamber. Infrared radiation can penetrate the powder coating and heat the substrate directly, which can help to cure the powder coating more quickly than other types of ovens. However, radiant ovens can also create hot spots, so it is important to use them with caution.

Infrared oven:

An infrared oven is a type of radiant oven that uses infrared emitters to generate infrared radiation. Infrared emitters can be gas-fired or electric. Gas-fired infrared emitters are typically more efficient than electric infrared emitters, but they can also produce more emissions.

Curing zone:

The curing zone is the part of the gas powder coating oven where the powder coating is cured. The curing zone is typically heated to a temperature of 150-200 degrees Celsius (300-390 degrees Fahrenheit) for a period of 10-30 minutes.

Cooling zone:

The cooling zone is the part of the gas powder coating oven where the parts are cooled after they have been cured. The cooling zone is typically not heated, but it may have fans to help circulate air and cool the parts more quickly.

Temperature control:

Temperature control is important for gas powder coating ovens because the curing process is temperature-sensitive. If the temperature is too low, the powder coating will not cure properly. If the temperature is too high, the parts may warp or crack.

Uniformity:

Uniformity is important for gas powder coating ovens because it ensures that all parts are exposed to the same temperature and time profile. This helps to prevent variations in the quality of the cured powder coating.

Efficiency:

Efficiency is important for gas powder coating ovens because it helps to reduce costs and energy consumption. Efficient ovens use less energy to cure the powder coating and they can process more parts per hour.

Energy consumption:

Energy consumption is an important consideration for gas powder coating ovens because they can be energy-intensive. Efficient ovens use less energy to cure the powder coating, which helps to reduce environmental impact.

How to use a gas powder coating oven

Here is how a gas powder coating oven operates:

- The parts to be coated are prepared. This involves cleaning and degreasing the parts to ensure that the powder coating will adhere properly.

- The powder coating is applied to the parts. This can be done using a variety of methods, including electrostatic spraying, fluidized bed dipping, or manual dipping.

- The parts are placed in the gas powder coating oven. The oven is heated to a specific temperature, which is typically between 350 and 400 degrees Fahrenheit.

- The powder coating melts and flows over the parts, forming a smooth, continuous film. The curing process typically takes 10 to 20 minutes, depending on the type of powder coating and the desired finish.

- Once the powder coating has cured, the parts are removed from the oven. The parts are now coated with a durable, long-lasting powder coating finish.

Gas powder coating ovens are a versatile and efficient way to apply powder coatings to a wide variety of parts. They are used in a wide range of industries, including automotive, aerospace, appliance, and furniture manufacturing.

Here are some safety guidelines for operating a gas powder coating oven:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, a respirator, and long sleeves and pants.

- Make sure the oven is properly ventilated to remove fumes and dust.

- Ground the oven to prevent electrical shock.

- Do not overload the oven.

- Inspect the oven regularly for damage or wear and tear.

- Have a fire extinguisher nearby.

Gas powder coating ovens are a versatile and efficient way to cure powder coatings. By following the safety guidelines and operating instructions, you can ensure that your gas powder coating oven is safe and effective.

Powder coating of metals is often favored by manufacturers because its finish is tougher than conventional paint. Powder coating is abrasion resistant and will not crack, chip, or peel as conventional paint will. Powder coating is typically done through a two-step process:

First, the coating is applied to the part electrostatically with powder coating equipment, and then the newly powdered part is cured in an industrial gas powder coating oven under heat to form a skin.

This process is very efficient since the powder wraps around the back of the part for better coverage and ensures 95% material usage of the powder. The powder coating is a dust-like substance that behaves quasi-fluid. with the help of this material property, the powder coating flows through the hoses and gun of powder coating equipment and reaches the part already ionized with – ion.

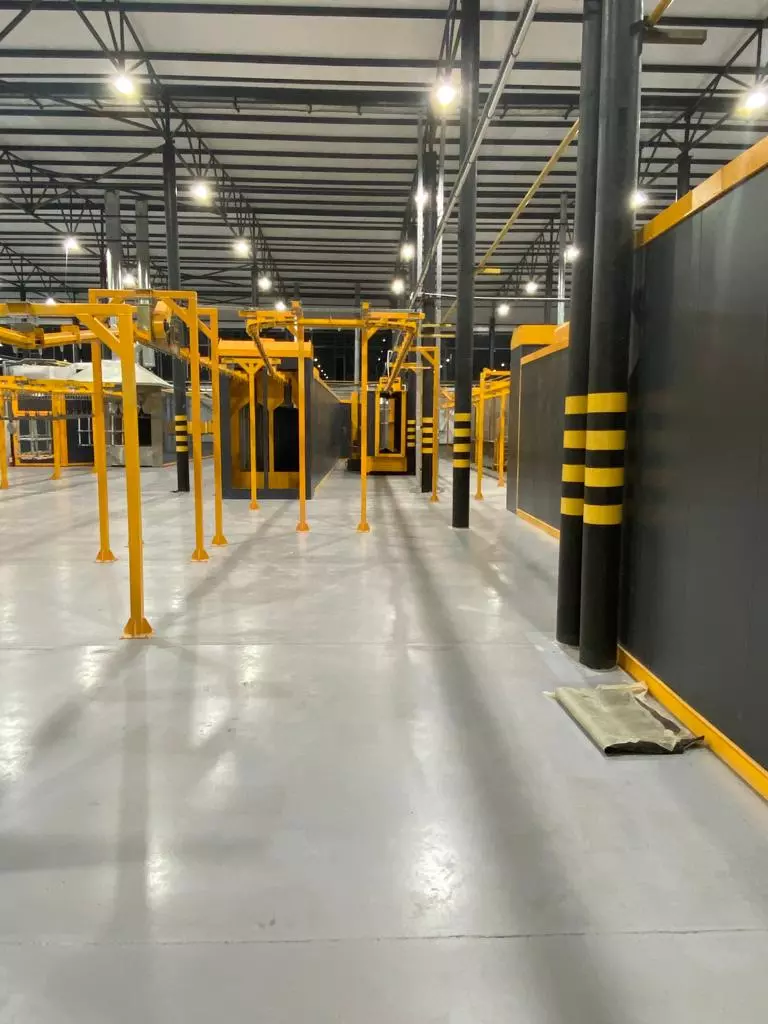

This helps the particle hang on the part and stay there till the part is grounded again. The parts that are coated with powder are either manually, or automatically with the help of a conveyor taken into the gas oven, which inside there is a 200 C temperature to melt the powder coating on the parts

Benefits of powder coating and curing in an oven: Heavy-duty construction and quality components Excellent uniformity and heating rates for consistent, high-quality curing results No powder blow-off – reduces rework Uniform heat distribution provides quality cured finishes and optimum cure cycles Quick heat-up rates so you can cure more loads per day Roof-mounted blowers conserve valuable floor space at your facility Fully adjusted and factory tested prior to shipment to reduce installation and start-up times Available with our exclusive energy-efficient oven upgrade

Environmental impact:

Gas powder coating ovens can have an environmental impact due to the emissions they produce. These emissions can include carbon dioxide, nitrogen oxides, and volatile organic compounds (VOCs). However, gas powder coating ovens are typically more energy-efficient than electric ovens, which can help to reduce their overall environmental impact.

Safety:

Safety is an important consideration for gas powder coating ovens because they use natural gas or propane, which are flammable fuels. It is important to ensure that gas powder coating ovens are properly installed and ventilated to prevent the risk of fire or explosion. Operators should also be trained on how to operate the ovens safely.

Maintenance:

Regular maintenance is important for gas powder coating ovens to ensure that they are operating safely and efficiently. Maintenance tasks include cleaning the ovens, checking the burners and ignition systems, and calibrating the temperature controls.

Airflow:

Airflow is important for gas powder coating ovens because it helps to distribute heat evenly throughout the curing chamber and to remove fumes and VOCs. Proper airflow can help to prevent the buildup of hot spots and the emission of harmful pollutants.

Heat distribution:

Heat distribution is important for gas powder coating ovens because it ensures that all parts are cured evenly. If the heat is not distributed evenly, some parts may not be cured properly, while others may be damaged.

Insulation:

Insulation is important for gas powder coating ovens because it helps to trap heat and improve energy efficiency. Proper insulation can help to reduce the amount of heat that is lost from the curing chamber, which can save energy and reduce costs.

Construction materials:

The construction materials used to build gas powder coating ovens should be durable and able to withstand the high temperatures and harsh conditions of the curing process. Common construction materials include steel, aluminum, and stainless steel.

Size:

The size of a gas powder coating oven is an important consideration because it determines the number of parts that can be cured at the same time. The size of the oven should be based on the production needs of the facility.

Capacity:

The capacity of a gas powder coating oven is the maximum number of parts that can be cured at the same time. The capacity of the oven should be based on the production needs of the facility.

Loading and unloading:

The loading and unloading of parts into and out of a gas powder coating oven should be done safely and efficiently. Proper loading and unloading procedures can help to prevent injuries and reduce downtime.

The Parts to be Coated are Prepared

Degreasing is the process of removing dirt, oil, and grease from the parts. This is important to ensure that the powder coating will adhere properly. Degreasing can be done using a variety of methods, including solvent cleaning, vapor degreasing, and alkaline cleaning.

Sanding is the process of removing any rust or corrosion from the parts. It can also be used to create a rougher surface, which will help the powder coating to adhere better. Sanding can be done using a variety of tools, including hand sanders, power sanders, and blast cabinets.

Once the parts have been degreased and sanded, they are ready to be powder coated.

The Powder Coating is Applied to the Parts

There are three main methods for applying powder coating to parts:

- Electrostatic spray: This is the most common method of applying powder coating. The powder is charged electrostatically and then sprayed onto the grounded part. The electrostatic charge attracts the powder to the part, resulting in a uniform coating.

- Fluidized bed dipping: The parts are dipped into a fluidized bed of powder coating. The fluidized bed is a tank of powder that has been agitated to create a fluid-like state. When the part is dipped into the fluidized bed, the powder coats the part evenly.

- Manual dipping: The parts are manually dipped into a vat of powder coating. This method is less common than electrostatic spray and fluidized bed dipping, but it can be used for small parts or complex shapes.

Once the powder coating has been applied, the parts are placed in a gas powder coating oven to cure the powder coating. The curing process melts the powder coating and flows it over the parts, forming a smooth, continuous film.

The choice of application method will depend on the size and shape of the parts, the type of powder coating being used, and the desired finish quality.

The Parts are Placed in the Gas Powder Coating Oven

Once the powder coating has been applied, the parts are placed in a gas powder coating oven to cure the powder coating. The curing process melts the powder coating and flows it over the parts, forming a smooth, continuous film.

The parts are typically placed on racks or hangers and loaded into the oven. The oven door is then closed and the oven is heated to the specified curing temperature. The curing time will vary depending on the type of powder coating and the desired finish quality.

Once the curing process is complete, the oven door is opened and the parts are removed. The parts are now coated with a durable, long-lasting powder coating finish.

Here are some safety guidelines for loading and unloading parts from a gas powder coating oven:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Be careful not to overload the oven. Overloading the oven can restrict airflow and increase the risk of fire.

- Allow the parts to cool completely before handling them.

- Use caution when removing the parts from the oven, as they may be hot.

By following these safety guidelines, you can help to ensure that the process of loading and unloading parts from a gas powder coating oven is safe and efficient.

The Powder Coating Melts and Flows Over the Parts, Forming a Smooth, Continuous Film

Yes, the powder coating melts and flows over the parts, forming a smooth, continuous film. Here is an image of the powder coating melting and flowing over the parts:

The melting and flowing of the powder coating is an important part of the curing process. During the curing process, the powder coating particles melt and fuse together to form a solid film. This film is what protects the parts from corrosion and other damage.

The melting and flowing of the powder coating is also important for achieving a high-quality finish. The smooth, continuous film that is created by the melting and flowing of the powder coating gives the parts a uniform appearance and protects them from scratches and other blemishes.

Here are some factors that can affect the melting and flowing of the powder coating:

- Type of powder coating: Different types of powder coatings have different melting points and flow characteristics.

- Curing temperature: The curing temperature must be high enough to melt the powder coating particles, but not so high that it causes the powder coating to overheat and decompose.

- Curing time: The curing time must be long enough to allow the powder coating particles to melt and fuse together completely.

- Airflow: Proper airflow in the oven is important for ensuring that the powder coating particles are heated evenly and that the powder coating cures properly.

By carefully controlling the type of powder coating, curing temperature, curing time, and airflow, manufacturers can ensure that the powder coating melts and flows properly, resulting in a high-quality finish.

Once the Powder Coating has Cured, the Parts are Removed from the Oven

Once the powder coating has cured, the parts are removed from the oven. Here is an image of parts being removed from a gas powder coating oven:

The parts are typically removed from the oven using racks or hangers. It is important to allow the parts to cool completely before handling them, as they may be hot.

Here are some safety guidelines for removing parts from a gas powder coating oven:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Be careful not to overload the racks or hangers. Overloading the racks or hangers can cause them to collapse, which could damage the parts or injure workers.

- Allow the parts to cool completely before handling them.

- Use caution when removing the parts from the oven, as they may be hot.

By following these safety guidelines, you can help to ensure that the process of removing parts from a gas powder coating oven is safe and efficient.

Small Gas Powder Coating Oven

The dimensions of our small powder coating oven start from 1,2m x 1,2m x 1,2m. This is for lab powder coating applications. The lab-type oven is used to cure powder coating for samples and small items in a small number

Powder coating companies that are doing custom coating can have some special requests for small items and samples. They don’t want to heat up a big oven for this and require a small lab-type box oven.

This small oven can also be used for powder coating at home. Some people try to make their own DIY powder coating oven but this usually takes a long time for construction and can have some serious mistakes in manufacturing that can cause inefficiency and even danger to human life.

The powder coating cost usually increases in such DIY powder coating oven types. If the curing won’t be effective, you will need to use a powder coat remover to get the powder off the powder-coated metal has the entire powder coating process once again. The powder coating prices are not that low to let you repeat the same process again and again.

Gas Powder Coating Oven Characteristics

Temperature Controller

An Electronic Temperature Controller controls temperature conditions. It is a non-profiling type 1/16 DIN single channel controller that features automatic control. Either a time proportioned heat output or a 4-20 ma control signal is used for precise temperature control

Overtemperature Protection

An Electronic Temperature Controller is provided for temperature protection. The Electronic Temperature Controller will remove power to the heating system when an over-temperature condition is detected. Alarm circuitry may be included as an option.

Process Timer

A Process Timer is provided, which has five user-selectable timing ranges from 0.01 seconds to 9999 hours. The timer will automatically start timing once the process setpoint temperature is reached. When the total preset time has elapsed, power to the heat control circuitry will be disabled.

Additional Features

EMS Powder Coating Equipment ovens are designed with the capability to incorporate many other optional features for safety purposes, enhanced process control, and a simplified operator interface. Consult a Gruenberg Applications Engineer or our Service Department for more information or questions.

Operating Parameters and Requirements

This equipment is designed to operate safely when the following environmental conditions are met:

- Indoor use only.

- Within a temperature range of 5°C to 90°C (max).

- Maximum relative humidity 90%.

The listed chamber specifications are based on operation at 24° C ambient temperature, the altitude at sea level, and a 60 Hz power supply. Chamber operation utilizing a 50 Hz power supply may derate the listed performance specifications. Equipment damage, personal injury, or death may result if this equipment is operated or maintained by untrained personnel.

Operators and service personnel must be familiar with the location and function of all controls and the inherent dangers of the equipment before operating or maintaining it. TPS shall not be liable for any damages, including incidental and/or consequential damages, regardless of the legal theory asserted, including negligence and/or strict liability.

Observe all safety warnings and operating parameters listed in this manual, as well as all Caution, Danger, and Warning signs or labels mounted on the equipment to reduce the risk of equipment damage and personal injury.

Automation:

Automation can be incorporated into gas powder coating ovens to improve efficiency, consistency, and safety. Automated systems can handle tasks such as loading and unloading parts, controlling temperature and curing times, and monitoring oven performance. This can help to reduce operator error, improve product quality, and minimize the risk of accidents.

Monitoring:

Monitoring systems can be used to track the performance of gas powder coating ovens and identify potential problems. These systems can monitor temperature, airflow, and other critical parameters to ensure that the ovens are operating safely and efficiently. Alarms can be triggered to alert operators to potential problems, allowing them to take corrective action before a problem occurs.

Data logging:

Data logging systems can be used to collect and record data from gas powder coating ovens. This data can be used to track oven performance over time, identify trends, and troubleshoot problems. Data logging can also be used to create reports for quality control and regulatory compliance purposes.

Troubleshooting:

Troubleshooting is the process of identifying and resolving problems with gas powder coating ovens. Common troubleshooting tasks include checking burners and ignition systems, calibrating temperature controls, and addressing airflow issues. Operators should be trained on how to troubleshoot common problems with the ovens they operate.

Types of gas powder coating ovens:

There are several different types of gas powder coating ovens available, each with its own advantages and disadvantages. The most common types of gas powder coating ovens include:

- Convection ovens: Convection ovens use fans to circulate hot air throughout the curing chamber, ensuring even heat distribution.

- Radiant ovens: Radiant ovens use infrared radiation to heat the curing chamber, which can cure parts more quickly than convection ovens.

- Infrared ovens: Infrared ovens use infrared emitters to generate infrared radiation. Infrared emitters can be gas-fired or electric.

Applications of gas powder coating ovens:

Gas powder coating ovens are used in a wide variety of applications, including:

- Automotive manufacturing: Gas powder coating ovens are used to coat car parts, such as bumpers, wheels, and frames.

- Appliance manufacturing: Gas powder coating ovens are used to coat appliances, such as refrigerators, stoves, and washers.

- Industrial manufacturing: Gas powder coating ovens are used to coat industrial equipment, such as machinery, tools, and parts.

Benefits of using gas powder coating ovens:

There are several benefits to using gas powder coating ovens, including:

- Energy efficiency: Gas powder coating ovens are typically more energy-efficient than electric ovens.

- Faster curing times: Gas powder coating ovens can cure parts more quickly than electric ovens.

- Uniform coating: Gas powder coating ovens can provide a more uniform coating than wet paint applications.

Limitations of gas powder coating ovens:

There are also some limitations to using gas powder coating ovens, including:

- Emissions: Gas powder coating ovens can produce emissions, such as carbon dioxide, nitrogen oxides, and VOCs.

- Safety: Gas powder coating ovens use flammable fuels, so it is important to ensure that they are properly installed and ventilated.

- Cost: Gas powder coating ovens can be more expensive than electric ovens.

Safety considerations for gas powder coating ovens:

There are several safety considerations for gas powder coating ovens, including:

- Proper installation and ventilation: Gas powder coating ovens should be installed and ventilated by a qualified technician.

- Training: Operators should be trained on how to operate gas powder coating ovens safely.

- Fire protection: Gas powder coating ovens should be equipped with fire suppression systems.

- Personal protective equipment (PPE): Operators should wear appropriate PPE, such as gloves, safety glasses, and respirators, when operating gas powder coating ovens.

Maintenance tips for gas powder coating ovens:

To ensure that gas powder coating ovens are operating safely and efficiently, it is important to perform regular maintenance. Maintenance tasks include:

- Cleaning: Regularly clean the ovens to remove dust, debris, and overspray.

- Inspection: Inspect the ovens regularly for signs of wear and damage.

- Calibration: Calibrate the temperature controls regularly.

- Servicing: Have the ovens serviced by a qualified technician annually.

Selecting the appropriate gas powder coating oven for your specific needs is crucial for achieving efficient and high-quality powder coating results. Here’s a comprehensive guide to assist you in making an informed decision:

- Assess Your Production Needs:

- Determine the size and volume of parts you intend to coat.

- Consider the desired curing times and production throughput.

- Evaluate the type of powder coating materials you’ll be using.

- Evaluate Oven Types and Features:

- Convection ovens offer even heat distribution and are suitable for a wide range of parts.

- Radiant ovens provide faster curing times and are ideal for heat-sensitive materials.

- Infrared ovens offer targeted heating and can be energy-efficient.

- Consider Energy Efficiency and Emissions:

- Gas powder coating ovens are generally more energy-efficient than electric ovens.

- Choose an oven with efficient burners and insulation to reduce energy consumption.

- Implement proper ventilation systems to minimize emissions.

- Safety and Ergonomics:

- Ensure the oven complies with safety standards and has proper fire suppression systems.

- Choose an oven with easy loading and unloading mechanisms to minimize operator strain.

- Provide adequate training and personal protective equipment for operators.

- Cost and ROI:

- Obtain quotes from leading gas powder coating oven manufacturers.

- Factor in installation, maintenance, and operational costs.

- Calculate the return on investment (ROI) to justify the purchase.

Leading Gas Powder Coating Oven Manufacturers:

- Dürr Systems

- Eisenmann

- Gema

- Reliant Finishing Systems

- Sprayshop Equipment USA

Gas Powder Coating Oven Resources:

- Powder Coating Institute (PCI)

- North American Association for Powder Coating (NAPCO)

- American Coating Association (ACA)

- Powder Coating Research Institute (PCRI)

Gas Powder Coating Oven Safety Data Sheets (SDS):

- Obtain SDS for the specific powder coating materials you’ll be using.

- Understand the potential hazards and handling precautions for each material.

- Implement proper storage, handling, and disposal procedures.

Gas Powder Coating Oven Installation Manuals:

- Follow the manufacturer’s installation manual precisely for safe and proper setup.

- Ensure the oven is installed in a well-ventilated area away from flammable materials.

- Connect electrical and gas connections according to local codes and standards.

Gas Powder Coating Oven Troubleshooting Guides:

- Familiarize yourself with common troubleshooting procedures for the specific oven model.

- Identify potential troubleshooting scenarios and their corresponding solutions.

- Contact the manufacturer’s technical support for assistance if necessary.

Gas Powder Coating Oven FAQs:

- Consult FAQs provided by manufacturers or industry resources to address common questions.

- Find answers to frequently asked questions about oven selection, operation, maintenance, and safety.

- Stay informed about latest advancements and best practices in powder coating technology.

Gas Powder Coating Oven Glossary:

- Understand the terminology used in gas powder coating ovens and related processes.

- Familiarize yourself with key terms such as curing zone, airflow, insulation, safety interlocks, and VOCs.

- Effectively communicate and collaborate with colleagues and suppliers using industry-standard terminology.

Location and Installation of the Gas Powder Coating Oven

- Oven Classification – Electric Heated Units: NFPA 86 Class B ovens are heat utilization equipment operating at approximately atmospheric pressure wherein there are no flammable volatiles or combustible material being heated in the oven.

- Oven Classification – Gas Heated Units: NFPA 86 Class A: “Class A ovens and furnaces are heat utilization equipment operating at approximately atmospheric pressure wherein there is a potential explosion or fire hazard that could be occasioned by the presence of flammable volatiles or combustible materials processed or heated in the furnace.”

- Do not locate units in areas of wide ambient temperature variation such as near vents or outdoor entrances.

- Do not place the unit near combustible materials or hazardous fumes or vapors.

- Do not install the unit in a corrosive environment. A corrosive environment may lead to poor performance and deterioration of the unit.

- Ventilation: The oven should be installed in an area where there is good air ventilation. Allow a minimum of 5 inches between any wall and any oven side.

- Do not position the oven in a manner that would make it difficult to operate your main power disconnect switch.

- Make sure the oven is leveled when set up. The floor of the chamber should be leveled with a Spirit Level to +/- 1/8” (3.175 mm) front to back and side to side.

- Sometimes control panels are removed to facilitate shipment. When required, replace the panel securely and reconnect numbered electrical wires to matching numbered terminal blocks.

Very Important! Upon completion of the initial installation of the chamber and upon completion of any maintenance procedure, make sure that all access panels that have been removed are reinstalled securely before operating the unit.

Exhaust Connection for Gas Powder Coating Oven

An exhaust port connection consisting of a 6” O.D. collar is installed with the exhaust blower assembly at the top of the oven. The exhaust housing includes a manual damper. A vent duct should be connected to the exhaust port collar and run to a location outside of the building (as necessary). This should be done in accordance with all local code regulations. Make sure the connection is secure.

Gas Supply Connection for Gas Powder Coating Oven

Gas-fired ovens may use either natural gas or liquid propane for combustion to heat the oven. You must follow your specific supply specifications listed on your General Arrangement Drawing D001 and when listed here.

Important! Please read the entire Gas Heating System section and all vendor manuals / cut sheets to familiarize yourself with all gas components before making your gas supply connection. The gas supply connection is made to a ball valve with a ½” FPT type connection. Make sure the connection is secure and is checked for leaks before operation.

Gas Supply – Liquid Propane: Pressure = xxx PSIG, xxxx CFH

Gas Supply – Natural Gas: Pressure = xxx PSIG, xxxx CFH

Air Circulation of Gas Powder Coating Oven

Gas-fired heating systems are normally installed in walk-in modular ovens. A high-volume airflow system is employed to provide maximum temperature uniformity. The type of air circulation system used depends on the configuration of the unit.

Single module units can only employ a horizontal front-to-back airflow type pattern using centrifugal type blower wheels to generate air circulation. Double module units can employ two different types of air circulation systems, as listed below.

- Horizontal front-to-back pattern using centrifugal type blower wheels.

- Compound horizontal pattern using propeller-type fans.

The heating and generation of airflow occur in the conditioning plenum, which is normally located on the right side wall of the oven.

Blower wheels or fans are driven with extended shafts by motors mounted in the control cabinet. Heating is achieved by a gas burner that directs a flame down into a vertical perforated flame tube mounted in the manifold next to the conditioning plenum. Thermocouples used for temperature sensing are normally mounted in the workspace on the plenum panel.

Airflow Description

Gas ovens using centrifugal type blower wheels for airflow generation employ a horizontal front-to-back type airflow system. The burner manifold is designed with a vertically mounted flame tube along with perforations on the back side of the manifold. Processed air is drawn into the burner manifold and conditioning plenum, and is heated as it mixes with hot air emitted from the flame tube.

Fresh ambient air is also drawn into the plenum where it mixes with the heated air. Conditioned air is discharged into the workspace through perforations near the front of the plenum housing. The air flows back through the workspace in a horizontal manner to condition the product and then returns to the plenum for reconditioning.

A portion of the processed air is exhausted through a port in the chamber ceiling by the exhaust blower. An air intake port with a manual slide damper is installed in the ceiling of each module to allow fresh ambient air to replenish the exhausted air. Slide dampers are mechanically locked to a predetermined minimum opening.

Heating System of Gas Powder Coating Oven

Important Note: Due to the diverse array of configurations available in a gas heating system, this section will describe basic system requirements, standard equipment used, and fundamental operation.

EMS Powder Coating gas heated ovens are designed to operate with either a natural gas supply or a liquid propane supply according to NFPA 86 (National Fire Protection Association) safety standards. To meet NFPA main gas train requirements, a Closed Position Indicator CPI is used for electrical indication of the safety valve’s closed position. A direct-fired type gas system is used in which the flame is shot through a burner manifold in the conditioning plenum.

Recirculating oven air is heated as it is drawn through the flame. Direct-fired systems are typically greater than 90% efficient. Since products of combustion enter the workspace with this type, it is reserved for those processes that are not emission sensitive.

However, many safety precautions are employed with a direct-fired system to compensate for the presence of an open flame. The following sections detail the standard gas heating components used and their operation. The actual components used will vary with your application, so it’s important to check your oven specifications.

Exhaust Blower of the Gas Powder Coating Oven

An exhaust blower is standard with all direct-fired systems to serve two purposes. Initially, the blower is used along with a purge air timer to purge oven air for a fixed time before the gas burner is fired.

When the purge cycle time is complete, the exhaust blower is used to maintain a constant exchange of oven air with fresh ambient air. Ambient air is drawn into the oven through slide dampers mounted atop each module.

A differential pressure switch is used to monitor airflow generation by the exhaust blower, and subsequently for the correct operation of the blower motor. These devices use a diaphragm to sense pressure and to mechanically trigger an SPDT Snap Switch when the proper pressure is developed across the blower wheel (or fan).

Correct rotation of the motor is necessary for the switch to operate properly. If a loss of pressure/airflow were detected, the switch would open and remove power from the gas burner.

Loss of airflow may result from a motor malfunction, a loose blower wheel (or fan), or constricted air intake or exhaust ports. Blower Spark-Proof Design: The blower housing is designed with a non-sparking type construction. The housing and inlet rings are made of aluminum while the blower wheel is made of stainless steel. Should the blower wheel come off its shaft and strike the blower housing or inlet ring, no sparks can be generated between the two metals.

Oven Exhaust Issues

Gas convection cure ovens and some dry-off ovens are exhausted to remove raw fuel, byproducts of combustion, and any emissions from the coating materials. The coating materials may include compounds that are emitted by design, as well as decomposition byproducts from fallen powder or parts.

By necessity, ovens designed to cure conventional solvent-borne coatings must have much higher exhaust rates to remove hazardous solvents from the oven and work atmosphere. The removal of combustion byproducts is critically important to prevent the yellowing or darkening of light colors. General guidelines for powder cure ovens are:

- Three air turnovers per hour for non-appearance parts.

- Four to Six air turnovers per hour for dark colors.

- Six to Eight air turnovers per hour for clear coatings.

- Eight to Twelve air turnovers per hour for light colors and appearance parts.

Certain situations may require higher exhaust rates: - Curing solvent-borne or Ecoat in the same oven with powder. The

byproducts of these can interfere with powder cure or produce yellowing in light colors. - Curing multiple powder chemistries in the same oven environment can

produce gloss reduction and even wrinkling in a smooth coating. - Combination cure and dry-off ovens. High exhaust rates required to remove water vapor.

- Contaminated makeup air (plant air) is used rather than fresh outside air. The number of air turns in an oven is the rate at which fresh air replaces the initial air volume by the oven blower. The exhaust requirements can vary greatly with oven design.

Indirect burners represent far less of a problem with combustion gases than direct-fired burners. The air turns for direct-fired ovens should be higher. If the oven is exhausted over a period of time contaminants such as nitrous oxides and sulfur dioxide may build up to produce a condition known as a fouled oven.

In these cases, some coaters place buckets of liquid Ammonium Hydroxide or solid Ammonium Salts at the oven exit and entrance at shutdown to assist in neutralizing these acidic materials. Additionally, cleaning and servicing the burners may be necessary. The formula for determining Oven turns is:

Oven Turns = Make-up air exchange Rate/Oven Volume

Oven Residue

Many powder coating ovens have an oven fuzz that builds up in and around the cool zones such as the vestibule at the oven opening and around the exhaust fan. This material is generally made up of:

- Low molecular weight resins

- Flattening agents

- Blocking agents

- Degassing agents

- Decomposition products from the resin

The cause of build-up is generally caused by poor oven design or poor maintenance. This oven residue should be cleaned out by vacuuming or washing with a power spray washer.

Other factors which may contribute are: - The frequent line stops with a full load in the oven.

- Excessive oven temperatures

- Uneven heat in the oven results in hot and cool zones. This can result

from baffling, the placement of a cooling tunnel or poor insulation on the exterior facing walls.

Hazards associated with these residues are:

- Flammability

- Inhalation by workers

- Contamination of the finished part.

Note, even though not all residues represent fire hazards they should be treated as such.

Gas Burner – Combustion Blower

The three elements necessary for combustion are fuel, oxygen, and ignition. The combustion blower supplies a constant flow of fresh air to the burner. The air is mixed with gas by various methods in order to establish ignition and to sustain complete combustion. The combustion motor starts immediately when the OVEN ON switch is closed. A combustion airflow switch monitors airflow from the combustion blower. This is a differential air pressure type, which will shut down the burner if a loss of airflow is detected.

A burner is defined as a device used for the introduction of fuel and air into an oven at the required velocities, turbulence, and concentration to maintain ignition and combustion of fuel. A Blast type burner is normally

used. This burner delivers a combustible mixture under pressure, normally above 0.3 inch W.C. to the combustion zone. Various flame safety devices are installed within the burner.

Powder coating

Powder coating is a widely used finishing process in manufacturing, characterized by its ability to produce a high-quality, durable finish. The process involves the application of dry powder to a surface, which is then cured under heat to form a solid, protective coating. This process is favored in many industries due to its efficiency and environmental benefits compared to traditional liquid paint. Essential to the powder coating process are various pieces of equipment, including the Powder Coating Equipment, Powder Coating Booth, Powder Coating Spray Booth, Small Powder Coating Booth, and Powder Paint Booth with Filters.

Powder Coating Equipment Overview

Powder Coating Equipment encompasses a wide range of tools and machinery designed to facilitate the powder coating process. These include spray guns, booths, ovens, and automated systems. Each component plays a crucial role in ensuring the quality and efficiency of the coating process. For instance, Automatic Powder Coating Equipment is often used in large-scale operations where precision and consistency are paramount.

Powder Coating Booths

A Powder Coating Booth is a controlled environment where powder is applied to the substrate. These booths are designed to contain overspray, minimize contamination, and ensure even coating application. There are various types of booths, including the Small Powder Coating Booth, which is ideal for limited-space operations or for coating smaller parts. For larger operations, a Powder Coating Spray Booth is typically used, which allows for greater flexibility and efficiency.

Small Powder Coating Booths and Applications

Small Powder Coating Booths are specifically designed for operations that require a compact setup. These booths are particularly useful in small workshops or for businesses that specialize in coating small parts, such as Alloy Wheel Powder Coating. A Small Powder Coating Booth is typically paired with a Small Powder Coating Oven or a combined Small Powder Coating Booth and Oven to streamline the coating and curing processes.

Automated Powder Coating Systems

For businesses that require high throughput and consistent quality, an Automated Powder Coating System is often the best choice. These systems integrate various components of the powder coating process, including automated spray guns, conveyor systems, and curing ovens. By automating these processes, manufacturers can achieve a higher level of efficiency and reduce the potential for human error.

Ovens in Powder Coating

Curing ovens are an essential part of the powder coating process. They provide the heat necessary to cure the powder and form a durable coating. There are different types of ovens, including Gas Powder Coating Oven, Diesel Powder Coating Oven, and Portable Powder Coating Oven. Each type of oven offers distinct advantages depending on the application. For instance, a Gas Powder Coating Oven is known for its energy efficiency and consistent temperature control, while a Diesel Powder Coating Oven is favored in environments where gas supply is limited or where diesel is more readily available.

Portable Powder Coating Ovens

Portable Powder Coating Ovens are a versatile solution for businesses that require mobility in their operations. These ovens can be moved easily to different locations, making them ideal for on-site jobs or businesses with limited space. Despite their portability, these ovens are capable of delivering high-quality curing results comparable to their stationary counterparts.

Specialized Coating Applications: Alloy Wheel Powder Coating

Alloy Wheel Powder Coating is a specialized application of powder coating that involves applying a durable finish to alloy wheels. This process not only enhances the appearance of the wheels but also provides protection against corrosion and wear. The equipment used for this application typically includes a Small Powder Coating Booth and Oven to accommodate the size of the wheels and ensure a thorough and even coating.

Small Powder Coating Booths and Ovens

Combining a Small Powder Coating Booth with a Small Powder Coating Oven is an effective setup for operations that deal with smaller parts. This combination allows for a seamless transition from coating to curing, ensuring that the coated parts are handled efficiently and without the risk of contamination or damage.

Advantages of Automatic Powder Coating Equipment

The use of Automatic Powder Coating Equipment provides several advantages, particularly in high-volume production settings. Automation ensures that each part is coated with precision and consistency, reducing waste and increasing productivity. Additionally, automated systems can be programmed to handle various part sizes and shapes, making them a versatile option for manufacturers.

Conclusion

In conclusion, powder coating is an essential process in many industries, offering a durable and high-quality finish that is both environmentally friendly and cost-effective. The equipment used in this process, including Powder Coating Equipment, Powder Coating Booths, Automated Powder Coating Systems, and various types of ovens, plays a crucial role in achieving the desired results. Whether you are operating a small workshop or a large-scale manufacturing facility, the right combination of equipment can significantly enhance your production capabilities and product quality.

Powder Coating Equipment

Powder Coating Equipment encompasses a variety of tools and machines that are essential for applying powder coatings to various substrates. This equipment typically includes:

- Powder Spray Guns: These are devices used to apply the powder evenly onto the surface of the object. They can be manual or automated, with the latter offering greater consistency and efficiency.

- Powder Coating Booths: These are enclosed areas where the powder is applied, designed to contain overspray and prevent contamination.

- Curing Ovens: After the powder is applied, the coated object is placed in an oven to cure, which involves melting the powder so it flows together to form a smooth, solid coating.

- Control Systems: These systems manage the application parameters, such as temperature, spray rate, and curing time, ensuring the process is consistent and repeatable.

Powder Coating Booth

A Powder Coating Booth is a specialized enclosure designed to contain the powder application process. The booth serves several key functions:

- Overspray Containment: The booth ensures that any powder that doesn’t adhere to the substrate is captured and can often be recycled, reducing waste.

- Controlled Environment: By isolating the coating process, the booth minimizes contamination from dust and other particles, which could affect the finish quality.

- Airflow Management: Proper airflow within the booth ensures that the powder particles are evenly distributed and that overspray is efficiently collected.

There are various types of booths, such as open-faced booths, enclosed booths, and walk-in booths, each designed for different scales and types of operations.

Small Powder Coating Booth

A Small Powder Coating Booth is designed for operations that do not require large-scale equipment. These booths are ideal for small parts, prototypes, or businesses with limited space. Features of small booths include:

- Compact Design: These booths are smaller in size, making them suitable for tight spaces or mobile operations.

- Cost-Effective: They are often less expensive than larger booths, making them an economical choice for small businesses or hobbyists.

- Efficiency: Despite their size, small powder coating booths are equipped to handle a variety of coating tasks with high precision.

Powder Coating Spray Booth

A Powder Coating Spray Booth is a type of booth specifically designed to accommodate the spraying process of powder application. This type of booth is equipped with:

- Advanced Filtration Systems: These systems filter the air to remove any particles, ensuring a clean environment for the coating process.

- Adjustable Airflow: Airflow can be adjusted to optimize the application and ensure even coating on all surfaces.

- Ergonomic Design: Spray booths are often designed to maximize operator comfort and efficiency, with easy access to all areas of the parts being coated.

Powder Paint Booth with Filters

A Powder Paint Booth with Filters is equipped with specialized filtration systems to capture overspray and maintain air quality within the booth. These filters play a critical role in:

- Ensuring Air Quality: Filters remove airborne powder particles, preventing them from escaping the booth and affecting the surrounding environment.

- Reducing Waste: Captured powder can often be recycled, reducing material costs and waste.

- Maintaining Finish Quality: Clean air within the booth ensures that the powder coating adheres smoothly and evenly, free from contaminants.

Automated Powder Coating System

An Automated Powder Coating System integrates various stages of the powder coating process into a seamless, automated workflow. Key features of these systems include:

- Conveyor Systems: Parts are transported automatically through the different stages of coating and curing, increasing efficiency and throughput.

- Automated Spray Guns: These guns apply powder coatings consistently across parts, reducing the potential for human error and ensuring uniformity.

- Real-Time Monitoring: Sensors and control systems monitor the process in real-time, adjusting parameters as needed to maintain optimal coating conditions.

- Scalability: Automated systems can be scaled to meet the demands of different production volumes, from small batches to large-scale manufacturing.

Gas Powder Coating Oven

A Gas Powder Coating Oven is used to cure powder-coated parts by heating them to the required temperature. These ovens are powered by natural gas and offer several advantages:

- Energy Efficiency: Gas ovens are generally more energy-efficient than electric ovens, making them a cost-effective option for large-scale operations.

- Consistent Heating: They provide uniform temperature distribution, which is crucial for achieving a consistent and durable finish.

- Fast Heat-Up Times: Gas ovens typically heat up faster than electric ovens, reducing cycle times and increasing productivity.

Diesel Powder Coating Oven

A Diesel Powder Coating Oven is similar to a gas oven but is powered by diesel fuel. These ovens are often used in situations where:

- Fuel Availability: Diesel may be more readily available or more economical than gas in certain regions or for certain operations.

- High-Temperature Requirements: Diesel ovens are capable of reaching high temperatures quickly, making them suitable for heavy-duty applications.

- Portability: Some diesel ovens are designed to be portable, allowing them to be moved to different locations as needed.

Portable Powder Coating Oven

A Portable Powder Coating Oven is designed for mobility, allowing it to be transported to different job sites or easily repositioned within a workshop. Features include:

- Compact Size: Portable ovens are generally smaller and lighter than stationary models, making them easy to move.

- Versatility: These ovens can be used for a variety of applications, from small parts to on-site repairs and custom jobs.

- Flexibility: They can be powered by different fuel sources, including gas, diesel, or electricity, depending on the specific model.

Alloy Wheel Powder Coating

Alloy Wheel Powder Coating is a specialized process designed to coat alloy wheels with a durable and attractive finish. The process involves:

- Preparation: The wheels are first cleaned and prepped to ensure the powder coating adheres properly.

- Application: A powder coating is applied evenly across the wheel, often using a Small Powder Coating Booth to contain the process.

- Curing: The coated wheels are then placed in an oven, where the powder is cured to form a hard, protective layer. This can be done in a Small Powder Coating Oven.

- Finishing: The final product is a wheel with a high-quality finish that resists chips, scratches, and corrosion.

Small Powder Coating Booth and Oven

A Small Powder Coating Booth and Oven setup is ideal for businesses or hobbyists who need to coat small parts efficiently. This setup typically includes:

- A Compact Booth: The booth is designed to fit in smaller spaces while still providing the necessary environment for powder coating.

- A Small Oven: The oven is sized to match the booth, ensuring that parts can be cured immediately after coating, reducing handling and the risk of contamination.

- Integrated Systems: Some setups may combine the booth and oven into a single unit, making it easier to manage the process in a limited space.

Small Powder Coating Oven

A Small Powder Coating Oven is specifically designed for curing smaller items. Key benefits include:

- Space Efficiency: These ovens are designed to fit into smaller workshops or production areas, making them ideal for limited-space environments.

- Quick Heat-Up: Smaller ovens generally heat up faster, allowing for shorter cycle times and increased productivity.

- Cost-Effective: Due to their smaller size, these ovens typically consume less energy, making them a more economical option for small businesses or low-volume operations.

Automatic Powder Coating Equipment

Automatic Powder Coating Equipment refers to systems designed to automate the powder coating process, offering numerous advantages:

- Consistency: Automated equipment ensures that each part is coated evenly, reducing variability and ensuring high-quality finishes.

- Efficiency: Automation reduces the time required to coat each part, increasing throughput and reducing labor costs.

- Advanced Features: Many automated systems include features such as programmable control systems, which allow for precise adjustments to coating parameters, and integration with other manufacturing processes, such as pre-treatment and inspection.

Introduction to Powder Coating and Essential Equipment

Powder coating is an advanced finishing process widely recognized for its efficiency, durability, and environmental benefits. Unlike traditional liquid paint, powder coating uses a dry powder that is electrostatically charged and sprayed onto a surface. The coated surface is then cured under heat, forming a robust and protective layer. This process is employed across various industries, including automotive, aerospace, and consumer goods, due to its superior finish quality and resistance to wear and corrosion.

The success of powder coating depends heavily on the equipment used throughout the process. Powder Coating Equipment includes a wide range of machinery designed to ensure that the powder is applied evenly and cured properly. This equipment encompasses spray guns, booths, ovens, and automated systems that work together to deliver a consistent, high-quality finish. Each piece of equipment serves a specific purpose, and understanding their functions and benefits is crucial for optimizing the powder coating process.

Powder Coating Equipment: A Comprehensive Overview

Powder Coating Equipment refers to the complete set of tools and machinery used in the powder coating process. This equipment includes:

- Electrostatic Spray Guns: These are the primary tools used to apply powder to the substrate. The spray gun charges the powder particles, causing them to adhere to the surface of the part being coated. There are different types of spray guns, including manual and automated versions, each suited for specific applications.

- Powder Coating Booths: These enclosures provide a controlled environment for applying the powder, ensuring that overspray is contained and that the powder is applied uniformly. The booths are designed to maximize efficiency and minimize waste, often incorporating filtration systems to capture excess powder for reuse.

- Curing Ovens: Once the powder has been applied, the coated part is transferred to a curing oven. These ovens heat the part to the required temperature, causing the powder to melt and flow into a smooth, even coating. Different types of ovens, such as gas, diesel, and portable ovens, are used depending on the size of the part and the specific needs of the operation.

- Automated Systems: In larger-scale operations, Automatic Powder Coating Equipment is often used to streamline the process. These systems can automate the entire powder coating process, from powder application to curing, improving efficiency and consistency.

The Role of Powder Coating Booths

A Powder Coating Booth is an essential component of the powder coating process, providing a dedicated space for the application of powder coatings. These booths are designed to create an optimal environment for powder application, with features that include:

- Controlled Airflow: Proper airflow is critical in a powder coating booth. It ensures that the powder particles are evenly distributed and that overspray is captured efficiently. The airflow is carefully managed to prevent contamination and to ensure that the powder adheres uniformly to the substrate.

- Containment of Overspray: A key function of the booth is to contain overspray, preventing powder from spreading to other areas of the workspace. This not only keeps the work environment clean but also allows for the recovery and reuse of overspray, reducing waste and saving on material costs.

- Variety of Configurations: Powder coating booths come in various configurations to suit different applications. For example, walk-in booths are used for coating large parts, while compact booths are ideal for smaller operations.

Small Powder Coating Booth: Efficiency in Compact Spaces

A Small Powder Coating Booth is specifically designed for operations with limited space or for businesses that focus on coating smaller parts. Despite their size, these booths offer several advantages:

- Space-Saving Design: The compact size of a small powder coating booth makes it ideal for workshops or production areas where space is at a premium. These booths are designed to fit into tight spaces without compromising on performance or safety.

- Cost-Effective Operation: Small booths typically require less energy and resources to operate, making them a cost-effective option for small businesses or for coating small batches of parts. They are also easier to install and maintain, reducing overall operating costs.

- Versatility: These booths can handle a wide range of coating tasks, from small automotive parts to prototypes and custom jobs. Their versatility makes them a popular choice for businesses that require flexibility in their operations.

Powder Coating Spray Booth: Optimized for Precision Application

A Powder Coating Spray Booth is a specialized booth designed to optimize the spray application of powder coatings. These booths are equipped with advanced features that enhance the coating process:

- High-Efficiency Filtration Systems: The filtration systems in a spray booth are designed to capture overspray and remove airborne particles, ensuring a clean environment for powder application. This is crucial for achieving a high-quality finish and for maintaining a safe work environment.

- Adjustable Airflow: The airflow in a spray booth can be adjusted to suit the specific requirements of the coating job. This allows for precise control over the application process, ensuring that the powder is applied evenly and with the desired thickness.

- Operator-Friendly Design: Spray booths are designed with the operator in mind, providing easy access to the parts being coated and ergonomic features that reduce fatigue. This improves both the efficiency and safety of the coating process.

Powder Paint Booth with Filters: Ensuring Quality and Safety

A Powder Paint Booth with Filters is a critical component of the powder coating process, providing an enclosed space for the application of powder coatings while ensuring that air quality is maintained. The filtration system in these booths serves several important functions:

- Air Quality Control: The filters in a powder paint booth are designed to capture airborne powder particles, preventing them from contaminating the workspace and ensuring that the air remains clean and breathable. This is particularly important in environments where multiple coating operations are taking place simultaneously.

- Waste Reduction: By capturing overspray, the filtration system helps to reduce waste, as the collected powder can often be recycled and reused. This not only reduces material costs but also minimizes the environmental impact of the coating process.

- Compliance with Regulations: Powder paint booths with filters are often required to meet specific safety and environmental regulations, particularly in industries where hazardous materials are used. The filtration system ensures that the booth operates within these guidelines, protecting both workers and the environment.

Automated Powder Coating System: Enhancing Productivity and Consistency

An Automated Powder Coating System integrates various components of the powder coating process into a fully automated workflow. These systems are designed to improve productivity, consistency, and efficiency in large-scale operations. Key features include:

- Conveyor Systems: Automated systems often incorporate conveyor belts that transport parts through the different stages of the coating process. This allows for continuous production, reducing downtime and increasing throughput.

- Robotic Spray Guns: Robotic arms equipped with spray guns can apply powder coatings with a high degree of precision, ensuring that each part is coated uniformly. This reduces the risk of defects and improves the overall quality of the finish.

- Real-Time Monitoring and Control: Advanced sensors and control systems monitor the coating process in real-time, adjusting parameters as needed to maintain optimal conditions. This ensures consistent results, even in high-volume production environments.

- Scalability: Automated powder coating systems can be scaled to meet the needs of different production volumes, from small batches to large-scale manufacturing. This makes them a versatile solution for a wide range of industries.

Gas Powder Coating Oven: Reliable and Efficient Curing

A Gas Powder Coating Oven is a critical piece of equipment in the powder coating process, providing the heat necessary to cure the powder coating and form a durable, protective layer. These ovens are powered by natural gas and offer several advantages:

- Energy Efficiency: Gas ovens are known for their energy efficiency, as they can heat up quickly and maintain a consistent temperature with minimal energy consumption. This makes them a cost-effective option for large-scale operations.

- Uniform Heating: The design of gas ovens ensures that heat is distributed evenly throughout the oven, preventing hot spots and ensuring that all parts are cured uniformly. This is essential for achieving a consistent, high-quality finish.

- Flexible Operation: Gas powder coating ovens can be used for a wide range of applications, from small parts to large assemblies. They are also available in various sizes and configurations, making them adaptable to different production needs.

Diesel Powder Coating Oven: Power and Portability

A Diesel Powder Coating Oven is similar to a gas oven but is powered by diesel fuel. These ovens are often used in situations where gas is not readily available or where diesel is more economical. The key benefits of diesel ovens include:

- High Heat Output: Diesel ovens are capable of reaching high temperatures quickly, making them ideal for heavy-duty applications that require fast curing times.

- Portability: Many diesel ovens are designed to be portable, allowing them to be easily moved to different locations as needed. This makes them a flexible option for businesses that need to perform coating operations on-site or in remote locations.

- Durability: Diesel ovens are built to withstand harsh conditions and are often used in industrial settings where durability and reliability are critical.

Portable Powder Coating Oven: Versatility on the Move

A Portable Powder Coating Oven offers the flexibility of being moved to different job sites or repositioned within a workshop. These ovens are ideal for operations that require mobility or for businesses with limited space. Key features of portable ovens include:

- Compact and Lightweight Design: Portable ovens are designed to be easily transported, with a compact size and lightweight construction that makes them easy to move and set up.

What is a Gas Powder Coating Oven?

A gas powder coating oven is an industrial curing oven that uses natural gas or propane as its primary energy source to generate the heat needed to cure powder coatings. These ovens are designed to create a controlled environment where the coated product is exposed to consistent, high temperatures, allowing the powder to melt, flow, and bond to the surface. The result is a hard, smooth, and durable finish that protects the product from wear, corrosion, and environmental damage.

Gas ovens are particularly effective for curing large quantities of products quickly, thanks to their fast heat-up times and ability to maintain steady temperatures over long periods. They are commonly used in industries such as automotive manufacturing, metal fabrication, and industrial equipment production, where high volumes of parts need to be coated and cured efficiently.

How Gas Ovens Work

Gas powder coating ovens operate by burning natural gas or propane in a combustion chamber, which generates heat that is then circulated throughout the curing chamber. The combustion process is controlled by a burner system that regulates the flow of gas to maintain the desired temperature. Fans or blowers distribute the heated air evenly across the chamber, ensuring that the temperature remains consistent throughout the curing process.

The temperature inside the oven is typically controlled by a digital system that allows operators to set and monitor the curing temperature and time. This precise control is crucial for ensuring that the powder coating cures properly, achieving the desired finish and durability.

Gas powder coating ovens can be configured as batch ovens, where products are loaded into the oven in groups, or as conveyorized systems, where products move through the oven on a conveyor belt. Conveyorized systems are ideal for high-volume production environments where continuous throughput is required.

EMS Powder Coating Equipment manufactures gas ovens that offer precise temperature control and efficient fuel consumption. Their ovens are designed with advanced insulation and heat distribution systems that minimize energy loss while providing consistent curing temperatures, ensuring top-quality results.

The Benefits of Gas Powder Coating Ovens

Gas powder coating ovens are favored by many manufacturers for their efficiency, scalability, and ability to handle high-volume production. Below are some of the key benefits that make gas ovens a popular choice in the powder coating industry:

1. Fast Heat-Up Times and Consistent Temperature Control

One of the main advantages of gas powder coating ovens is their ability to heat up quickly. Gas ovens can reach their target temperature in a short amount of time, which is essential for maintaining high productivity in busy production environments. Once the desired temperature is reached, gas ovens are highly effective at maintaining that temperature consistently throughout the curing process.

Consistent temperature control is critical in the powder coating process, as even minor fluctuations in heat can lead to uneven curing or defects in the coating. Gas ovens are equipped with advanced burner and airflow systems that ensure uniform heat distribution across the entire curing chamber. This helps prevent issues such as under-curing or over-curing, both of which can compromise the quality and durability of the final product.

EMS Powder Coating Equipment provides gas ovens with cutting-edge temperature control technology, ensuring that the curing process is optimized for consistent, high-quality results. Their ovens are designed to minimize temperature fluctuations, allowing businesses to achieve flawless finishes on every batch of products.

2. Energy Efficiency and Lower Operating Costs

Gas ovens are known for their energy efficiency, particularly in large-scale operations where high volumes of products need to be cured. Natural gas and propane are typically more cost-effective than electricity, especially in regions where gas prices are lower or where the availability of gas is more reliable. As a result, gas ovens can offer significant cost savings over time compared to electric ovens, particularly for businesses that run their ovens continuously or for extended periods.

Gas ovens are also designed to optimize fuel consumption. Many modern gas ovens feature energy-saving technologies such as modulating burners, which adjust the flow of gas to maintain the desired temperature with minimal waste. This ensures that the oven operates efficiently, using only the amount of fuel needed to achieve the required heat output.

EMS Powder Coating Equipment designs its gas ovens with energy efficiency in mind. Their ovens are equipped with advanced fuel-saving features that help businesses reduce their energy consumption while maintaining optimal curing performance. By choosing an EMS gas oven, businesses can lower their operating costs and improve their bottom line.

3. Scalability for High-Volume Production

Gas powder coating ovens are ideal for high-volume production environments where large quantities of products need to be coated and cured quickly. The fast heat-up times and consistent temperature control of gas ovens make them well-suited for operations that require continuous throughput. Conveyorized gas ovens, in particular, allow for a steady flow of products through the curing chamber, ensuring that production lines can run smoothly without interruption.

For industries such as automotive manufacturing, metal fabrication, and heavy machinery, where large, heavy, or complex parts need to be coated, gas ovens provide the power and capacity needed to handle these demanding workloads. The ability to scale up production without sacrificing quality or efficiency is one of the key reasons why gas ovens are so popular in these industries.

EMS Powder Coating Equipment specializes in manufacturing gas ovens that can be scaled to meet the specific needs of different industries. Whether you need a batch oven for smaller production runs or a conveyorized system for continuous operation, EMS provides customized solutions that help businesses maximize their production capacity.

4. Durability and Longevity

Gas ovens are known for their durability and long-lasting performance, making them a reliable investment for businesses that require continuous operation. Built with high-quality materials and advanced engineering, gas ovens are designed to withstand the demands of industrial use, including exposure to high temperatures and heavy workloads.

The robust construction of gas ovens ensures that they can operate effectively over long periods without frequent breakdowns or the need for extensive maintenance. This reliability is crucial for businesses that rely on their ovens to keep production lines running smoothly.

EMS Powder Coating Equipment designs its gas ovens with durability in mind. Their ovens are built to last, with high-quality components that can withstand the rigors of continuous industrial use. EMS ovens require minimal maintenance, allowing businesses to focus on production without worrying about costly downtime.

5. Flexibility Across a Range of Industries

Gas powder coating ovens are versatile and can be used to cure a wide range of products across different industries. From automotive parts and industrial equipment to consumer goods and outdoor furniture, gas ovens are capable of curing products of various sizes, shapes, and materials.

In addition to their versatility, gas ovens can be customized to meet the specific needs of different production environments. Whether you need an oven with precise temperature control for sensitive coatings or a large-capacity oven for high-volume production, gas ovens offer the flexibility needed to accommodate different curing requirements.

EMS Powder Coating Equipment offers gas ovens that can be tailored to meet the unique needs of various industries. Their ovens are designed for maximum flexibility, ensuring that businesses can achieve optimal curing performance for a wide range of products.

6. Environmentally Friendly Options

While gas ovens rely on fossil fuels, they can still be designed with environmental considerations in mind. Many modern gas ovens are equipped with energy-efficient burners and heat recovery systems that minimize fuel consumption and reduce emissions. This makes gas ovens a more environmentally friendly option compared to older models that may be less efficient.

In addition, gas ovens produce fewer emissions than diesel ovens, making them a more sustainable option for businesses that are looking to reduce their environmental impact while maintaining high performance.

EMS Powder Coating Equipment is committed to sustainability and offers gas ovens with energy-efficient features that help businesses reduce their carbon footprint. Their ovens are designed to meet environmental standards while providing the performance needed for industrial powder coating applications.

Why Choose EMS Powder Coating Equipment for Gas Ovens?

When selecting a gas powder coating oven, businesses need a solution that offers reliability, efficiency, and scalability. EMS Powder Coating Equipment is a trusted manufacturer of gas ovens, offering advanced systems designed to meet the specific needs of industrial production. Here’s why EMS is the best choice for businesses looking to invest in high-quality gas powder coating ovens:

1. Advanced Temperature Control Technology

EMS gas ovens are equipped with cutting-edge temperature control systems that ensure precise and consistent heat throughout the curing process. This level of control is essential for achieving high-quality finishes and preventing defects caused by temperature fluctuations.

2. Customizable Solutions for Different Industries

Every business has unique production needs, and EMS understands the importance of offering customizable solutions. EMS gas ovens are available in a variety of sizes and configurations, allowing businesses to choose the oven that best fits their production line. Whether you need a batch oven for smaller jobs or a conveyorized system for high-volume production, EMS provides tailored solutions that maximize efficiency and output.

3. Energy Efficiency for Cost Savings

EMS Powder Coating Equipment designs its gas ovens with energy efficiency in mind. Their ovens are equipped with energy-saving features such as modulating burners and advanced insulation that reduce fuel consumption and lower operating costs. By investing in an EMS gas oven, businesses can improve their energy efficiency while maintaining top-tier curing performance.

4. Durability and Reliability