Electrostatic Fluidized Bed Powder Coating: Fluidized bed coating equipment is used in various industries (such as pharmaceuticals, food, and chemicals) to coat solid particles or granules with a layer of material, typically to modify their properties like taste, dissolution rate, or appearance.

What is a Fluidized Bed Coating System?

A fluidized bed involves suspending solid particles in an upward-flowing stream of gas (usually air), causing them to behave like a fluid. During coating, a liquid formulation (like a polymer solution or suspension) is sprayed onto the fluidized particles. The heated air dries the liquid, forming a solid coat.

Main Components of a Fluidized Bed Coater

- Product Chamber – Where the particles are fluidized and coated.

- Air Handling System – Provides and conditions the fluidizing air (heating, humidifying, filtering).

- Spray System – Includes nozzles to atomize the coating liquid (top-spray, bottom-spray [Wurster], or tangential-spray types).

- Exhaust System – Removes excess moisture and solvents.

- Control System – Monitors temperature, airflow, spray rate, etc.

Types of Fluidized Bed Coaters

- Top-Spray Coaters – Liquid is sprayed from the top; good for layering and granulation.

- Bottom-Spray (Wurster) Coaters – Precise coating with minimal agglomeration; ideal for controlled-release formulations.

- Tangential-Spray Coaters – Spray comes in from the side; suitable for larger particles or pellets.

Advantages

- Uniform coating distribution.

- Efficient drying and fast processing.

- Scalable from lab to industrial scale.

- Suitable for heat-sensitive materials (with appropriate control).

Applications

- Pharmaceutical: Taste masking, enteric coating, sustained-release tablets or pellets.

- Food: Flavor or nutrient encapsulation.

- Agrochemical: Controlled release of pesticides or fertilizers.

Fluidized bed coating equipment works by suspending solid particles in a stream of gas, allowing for uniform coating with a liquid formulation. The particles are fluidized by air, and a liquid is sprayed onto them, then dried to form a coating. These systems are used in various industries like pharmaceuticals for controlled-release formulations, food for flavor encapsulation, and agrochemicals for slow-release pesticides. The equipment typically includes a product chamber, an air handling system, a spray system, and an exhaust system, all controlled to ensure optimal conditions for coating and drying. Fluidized bed coaters are versatile, scalable, and efficient, making them ideal for both small-scale laboratory work and large industrial processes. The ability to coat uniformly while controlling parameters like temperature and spray rate makes them valuable for applications requiring precision, such as in the pharmaceutical industry.

In a fluidized bed coating process, the fundamental principle is to create a state where solid particles—typically powders, granules, or pellets—are suspended in an upward stream of air or another gas. This fluid-like behavior ensures that each particle is well exposed and separated from others, enabling a uniform coating to be applied. The coating material, usually in liquid form such as a solution, suspension, or emulsion, is introduced into the fluidized bed through specially designed spray nozzles. As the liquid coating hits the moving particles, it adheres to their surfaces. The continuous flow of heated air rapidly evaporates the solvent or carrier fluid, leaving behind a dry and even film of the desired coating substance.

The entire system is carefully engineered to balance fluidization, spraying, and drying simultaneously. The airflow must be strong enough to suspend the particles but not so intense that it ejects them from the chamber. Spray parameters such as droplet size, spray angle, and flow rate are finely controlled to ensure that the coating is distributed uniformly and doesn’t cause particle agglomeration or wetting issues. Temperature and humidity of the air also play crucial roles, as they affect the drying rate and the physical properties of the final coating.

There are several spray configurations used depending on the nature of the coating and the application. Top-spray systems are often used for layering and granulation purposes, where the coating liquid is sprayed from above onto the fluidized particles. Bottom-spray configurations, also known as Wurster systems, are more precise and are widely employed for applications requiring uniform coating thickness, such as in pharmaceutical dosage forms like pellets or microgranules for controlled or delayed drug release. Tangential-spray systems involve a side entry of the spray and are particularly suited for coating larger or heavier particles that benefit from a more horizontal motion within the chamber.

The versatility of fluidized bed coating technology lies in its ability to handle a wide range of coating materials—polymers, sugars, waxes, resins—and substrates, making it suitable for multiple sectors. In pharmaceuticals, this equipment is used to modify drug release profiles, protect active ingredients from moisture or light, and mask unpleasant tastes. In the food industry, it helps in encapsulating flavors, vitamins, or minerals, improving shelf life and stability. In agriculture, it is used to prepare coated seeds, fertilizers, and pesticides that release gradually over time, enhancing efficiency and reducing environmental impact.

Moreover, the technology is scalable, allowing manufacturers to transfer a process from a laboratory-scale unit to a full-scale production system with relative ease. Modern fluidized bed coaters are equipped with automated control systems that continuously monitor and adjust key parameters, ensuring consistent product quality and regulatory compliance. The combination of high efficiency, reproducibility, and adaptability makes fluidized bed coating an essential part of modern manufacturing in several high-tech and high-precision industries.

The efficiency and precision of fluidized bed coating systems are largely due to the integration of advanced process controls and engineering designs that ensure repeatability and scalability. In pharmaceutical manufacturing, for instance, strict regulations such as Good Manufacturing Practices (GMP) and FDA requirements necessitate the use of equipment that can maintain tight control over process variables. Fluidized bed coaters meet this demand through features such as programmable logic controllers (PLCs), real-time monitoring of inlet and exhaust air temperatures, airflow rates, atomization pressure, spray rates, and bed temperature. These systems often include process analytical technology (PAT) tools, which allow operators to monitor coating thickness, moisture content, and even particle behavior in real time using sensors and feedback loops.

In terms of design, the internal structure of a fluidized bed coater is optimized to promote even fluidization and to avoid issues like dead zones (where particles may stagnate) or channeling (where airflow bypasses the product). The geometry of the product container, the location and number of spray nozzles, and the configuration of the air distributor plate are all critical. For example, in a Wurster coating setup, the product container includes a cylindrical partition or draft tube that directs the particles into a controlled circulation pattern: particles are pulled up through the center where they are sprayed and then fall down along the outer wall to re-enter the spraying zone. This allows for extremely uniform coatings and minimal cross-contamination.

The drying efficiency of the system is another important factor, particularly for heat-sensitive materials. Because fluidized bed coaters expose a large surface area of the product to hot air while keeping the particles in constant motion, they achieve very fast drying rates without exposing the material to excessively high temperatures. This is critical when working with pharmaceuticals, enzymes, probiotics, and other bioactive compounds that could degrade under thermal stress. Additionally, advanced systems offer features like multi-stage drying, adjustable humidity control, and even integrated solvent recovery for processes involving organic solvents.

From a maintenance and operational standpoint, fluidized bed coaters are designed for ease of cleaning and quick changeovers, especially in multiproduct facilities. Many systems are built to support clean-in-place (CIP) or wash-in-place (WIP) procedures, which reduce downtime and contamination risk. Material contact surfaces are typically made of stainless steel and are highly polished to prevent material buildup. Filters, gaskets, and seals are designed for quick disassembly and replacement.

Energy efficiency and environmental impact are also increasingly important in the design of modern fluidized bed coaters. Manufacturers are incorporating energy recovery systems, such as heat exchangers that reclaim waste heat from exhaust air to preheat incoming air. They also use low-energy spray technologies and systems to minimize overspray and material loss. In environmentally sensitive applications, exhaust air may be treated with scrubbers, HEPA filters, or solvent recovery systems to ensure emissions remain within permissible limits.

Ultimately, fluidized bed coating technology offers a highly customizable and robust platform for product development and commercial production across industries. It provides unparalleled control over coating quality, allows for integration with granulation or drying steps, and supports a wide range of formulation strategies. Its ability to adapt to different materials, batch sizes, and performance requirements ensures that it remains a cornerstone of advanced particle processing in the pharmaceutical, food, chemical, and agricultural sectors.

To understand the practical application of fluidized bed coating, consider the development of a sustained-release pharmaceutical pellet. The objective in such a case is to ensure that the active pharmaceutical ingredient (API) is released gradually over time, providing a prolonged therapeutic effect and reducing dosing frequency. The process typically starts with the formation of drug-loaded cores, often referred to as nonpareils or starter pellets, which are made using extrusion-spheronization or direct pelletization techniques. These cores are then coated using a fluidized bed coater to impart the desired release profile.

The coating formulation usually contains a polymer or a combination of polymers that control the rate at which the drug diffuses out of the pellet. Commonly used polymers include ethylcellulose, which forms a semi-permeable membrane, or methacrylate-based copolymers like Eudragit, which can be tailored for pH-dependent or time-dependent release. Plasticizers such as triethyl citrate or polyethylene glycol are added to enhance film flexibility and adhesion. The coating solution may also contain pigments, surfactants, or pore-forming agents, depending on the final product requirements.

During the coating process, the pellets are fluidized in a column while the polymer solution is sprayed from a bottom-spray nozzle (Wurster configuration). This setup ensures that each pellet repeatedly passes through the spray zone, receiving even layers of the coating material. As the heated air passes through the bed, it rapidly dries the wet coating, solidifying it into a uniform film. The process continues until the desired coating weight gain is achieved, which directly influences the drug release rate. For instance, a 10% weight gain might result in a 12-hour release profile, while a 15% weight gain could extend release to 18 or 24 hours.

Process parameters such as inlet air temperature, product temperature, spray rate, atomizing pressure, and fluidization air volume are critical and must be carefully optimized. If the spray rate is too high relative to drying capacity, the particles can become over-wet and stick together, leading to agglomeration or uneven coating. If the temperature is too low, the solvent may not evaporate efficiently, compromising film formation. Conversely, overly high temperatures might dry the droplets before they reach the particle surface, resulting in poor adhesion or dusty coatings.

Once coating is complete, the product undergoes a curing step, which may involve storing the coated pellets under controlled temperature and humidity to allow the polymer chains to coalesce fully and form a continuous film. This step is especially important for aqueous coatings, where initial film formation may be incomplete. Stability testing follows, to assess how the coated product behaves under various environmental conditions, such as heat, humidity, and light. Dissolution testing is used to confirm that the release profile meets the intended specifications.

A similar approach is applied in the food industry for encapsulating sensitive ingredients like flavors, vitamins, or probiotics. Here, the goal may not be controlled release over time, but rather protection against degradation due to heat, moisture, or oxygen. For instance, vitamin C, which is highly unstable in the presence of light and oxygen, can be coated with a protective layer that dissolves only in the stomach. In these cases, the coating formulation might use materials like modified starches, shellac, or maltodextrins. The equipment and process principles remain largely the same, but the formulations and critical parameters differ based on the nature of the core material and the function of the coating.

The adaptability of fluidized bed coaters also allows them to support multi-layer coating processes. A single pellet can receive a sequence of coatings: first a sub-coating to improve adhesion, then a drug-containing layer, followed by a barrier layer, and finally an outer enteric or color coating. All of these layers can be applied in the same equipment with minimal intervention, making the process efficient and cost-effective.

Overall, fluidized bed coating systems are not just tools for applying a film—they are sophisticated platforms for engineering the behavior of particles in precise and reproducible ways. Through the intelligent selection of materials, meticulous control of process parameters, and robust system design, these technologies make it possible to tailor the physical, chemical, and functional properties of particulate products for a wide range of advanced applications.

Let’s explore how a fluidized bed coater is used in a real-world laboratory setting by walking through a simplified protocol for applying a sustained-release coating to pharmaceutical pellets. This type of protocol is commonly used during product development before scaling up to commercial manufacturing.

The process begins with a clear definition of objectives: in this case, creating a sustained-release formulation that delivers the active pharmaceutical ingredient (API) over 12 hours. Drug-loaded pellets (about 200–500 microns in diameter) are already prepared and sieved to ensure uniformity in size, which is crucial for consistent fluidization and coating. The coating material selected might be ethylcellulose, chosen for its water-insoluble properties, which retard drug release by forming a semi-permeable membrane around each pellet.

A coating solution is prepared by dissolving ethylcellulose in a suitable organic solvent like ethanol or isopropanol, or in water if an aqueous dispersion is used (such as Aquacoat® or Surelease®). A plasticizer such as triethyl citrate is added at 10–20% of the polymer weight to improve flexibility and prevent film cracking. The solution is mixed using a high-shear or magnetic stirrer and filtered to remove particulates that could clog the spray nozzle.

Next, the fluidized bed coater is prepared. In a lab setting, this might be a small unit with a product capacity of 100 grams to 2 kilograms. The product container is loaded with the pellets, and preheating begins. The inlet air is heated to a setpoint typically between 35°C and 45°C, depending on the sensitivity of the product. The airflow is adjusted to achieve stable fluidization, which is visually confirmed through a sight glass or by monitoring bed pressure drop.

The bottom-spray nozzle (Wurster insert) is selected for precise control. Before coating starts, the system is balanced: airflow, temperature, and nozzle air pressure are stabilized. The coating solution is pumped to the nozzle and atomized at pressures ranging from 1.5 to 2.5 bar. Spray rate is usually initiated at a conservative setting—say, 1.0 g/min—and then gradually increased while monitoring the product temperature and fluidization behavior. Throughout the process, operators continuously check for signs of over-wetting (clumping or sticking) or under-wetting (dust generation or poor coating adherence).

The coating is applied until the target weight gain is reached—say, 12% for a 12-hour release target. This is monitored using either real-time weighing or by sampling and weighing a small amount of the product periodically. During coating, outlet air temperature and humidity are closely monitored as they reflect the drying capacity of the system. For organic coatings, exhaust air may be routed through solvent recovery units or scrubbers to meet safety and environmental regulations.

After coating, the pellets are removed and subjected to a curing step. In a lab, this might involve placing the coated pellets in an oven at 40°C for 24 hours to allow the polymer chains to coalesce and form a continuous, defect-free film. This step significantly influences the final release behavior of the coated product. Without it, the film may be porous or uneven, leading to burst release or dose dumping.

Finally, the product is evaluated. Tests include:

- Particle size distribution using sieves or laser diffraction.

- Coating uniformity via scanning electron microscopy (SEM) or optical microscopy.

- Drug release testing in dissolution baths, simulating gastric and intestinal fluids under USP conditions.

- Stability testing under accelerated conditions (e.g., 40°C and 75% RH) to assess coating integrity over time.

Once the lab-scale process meets specifications, a scale-up plan is developed. This involves recalculating airflow, spray rates, and batch size based on the equipment geometry and process dynamics of larger coaters—often 10–100 times the size of the lab unit. A key challenge during scale-up is maintaining similar particle trajectories and drying conditions, which requires a deep understanding of fluid dynamics and heat/mass transfer principles in fluidized systems.

In industrial practice, further layers of automation are added, such as automated recipe controls, real-time weight monitoring, and closed-loop spray feedback systems to optimize reproducibility. However, the foundational steps—formulation design, parameter optimization, controlled application, and post-coating treatment—remain essentially the same across all scales.

Fluidized bed coaters, therefore, bridge the gap between precise formulation science and scalable industrial manufacturing. They are especially valuable in regulated sectors where product performance, consistency, and process validation are critical. Beyond pharmaceuticals, similar protocols are adapted for food and agrochemical coatings, often using more robust and less sensitive materials, but following the same engineering principles.

To further appreciate the sophistication of fluidized bed coating, it’s useful to look into the nuanced relationship between process parameters and product characteristics. In practice, every variable—from inlet air temperature to atomizing air pressure—plays a role in determining the quality of the final coated product. Small deviations can result in significant variations in coating uniformity, release profile, and physical integrity.

One of the most critical parameters is inlet air temperature, which affects both the drying rate and the surface morphology of the coating. If the temperature is too high, it can cause the solvent to evaporate too quickly, leading to a rough or porous film. In pharmaceutical applications, this may result in an uncontrolled release profile or film cracking. Conversely, too low a temperature can slow drying to the point where droplets coalesce on the particle surface, causing tackiness and agglomeration. Therefore, temperature is typically set just high enough to promote efficient drying without degrading heat-sensitive ingredients—usually in the range of 35°C to 55°C for aqueous systems and slightly lower for organic solvent-based systems due to the volatility of the solvents involved.

Atomizing air pressure and spray rate are tightly interlinked. The pressure needs to be high enough to generate fine droplets that can coat uniformly but not so high that they rebound from the particle surface or cause excessive turbulence. A finely atomized spray ensures that the droplets quickly form a thin, even coating and dry almost instantaneously as they contact the heated particles. Too high a spray rate, on the other hand, can overload the bed with liquid, leading to agglomeration and uneven coating. Therefore, these two variables are often adjusted in tandem during process development to achieve a stable spray-drying balance. This is why design of experiments (DoE) approaches are often used in R&D to optimize such multivariate systems.

Fluidization air volume determines the mobility of the particles in the bed. Insufficient airflow results in poor particle movement, creating dead zones and inconsistent coating. Excessive airflow can lead to attrition of coated particles or loss of fines through the filters. Ideal fluidization provides enough lift to keep the particles suspended in a stable, circulating pattern without causing mechanical stress or excessive turbulence.

Nozzle design and positioning also significantly impact coating performance. In bottom-spray Wurster systems, the nozzle is located at the base of the partition column, ensuring that particles are directed vertically through a narrow spray zone. This results in highly repeatable, controlled trajectories for each particle and minimizes the chances of bypassing the spray. For sensitive applications where even tiny defects in coating uniformity can affect drug release, Wurster configurations offer unmatched control. In contrast, top-spray systems, while less precise, are more commonly used for layering or granulating, where exact uniformity is less critical.

Bed load (the amount of material in the product chamber) influences how well the particles interact with the spray. Overloading the bed reduces circulation space, leading to clumping and uneven coating. Underloading can result in turbulent motion and inefficient use of spray solution. Most manufacturers determine optimal bed load based on both the chamber geometry and the size/density of the particles being coated.

An often underappreciated aspect of the fluidized bed coating process is coating material rheology—the viscosity and surface tension of the liquid being sprayed. These properties govern how the coating spreads over the particle surface and how quickly it forms a continuous film. A higher-viscosity formulation may require higher atomizing pressure to achieve adequate droplet size, but it also carries a higher risk of nozzle clogging and uneven application. Conversely, very low-viscosity coatings can penetrate too deeply into porous cores or dry too quickly, leading to defects. Surfactants and cosolvents are sometimes used to modulate these properties and achieve optimal coating behavior.

Analytical testing is crucial for confirming that all these tightly controlled parameters result in a product that meets specifications. Tools like near-infrared spectroscopy (NIR) and Raman mapping are used to non-invasively analyze coating thickness and uniformity, while high-performance liquid chromatography (HPLC) is employed to verify drug content and purity. Advanced dissolution testing, often using USP Apparatus I (basket) or II (paddle), is used to confirm that the coated pellets release the active ingredient at the intended rate and under simulated physiological conditions.

Finally, process scale-up brings its own set of challenges, primarily due to differences in heat and mass transfer, airflow dynamics, and equipment geometry. During scale-up, empirical relationships such as maintaining a constant spray flux (spray rate per unit area) or specific fluidization velocity (airflow per unit of bed cross-sectional area) are used as guidelines. However, scale-up is rarely linear and usually requires iterative fine-tuning. Modern scale-up efforts are aided by computational fluid dynamics (CFD) modeling, which simulates particle movement and airflow to optimize equipment design and operating conditions.

The depth and complexity of fluidized bed coating as a technology are matched by its versatility and reliability. Whether the goal is to produce a delayed-release pharmaceutical pellet, a moisture-resistant food granule, or a biodegradable agrochemical bead, the principles remain consistent. Mastery of this process enables formulators and process engineers to design advanced, functional particulate products with precisely controlled characteristics—truly a cornerstone of modern solid dosage form manufacturing.

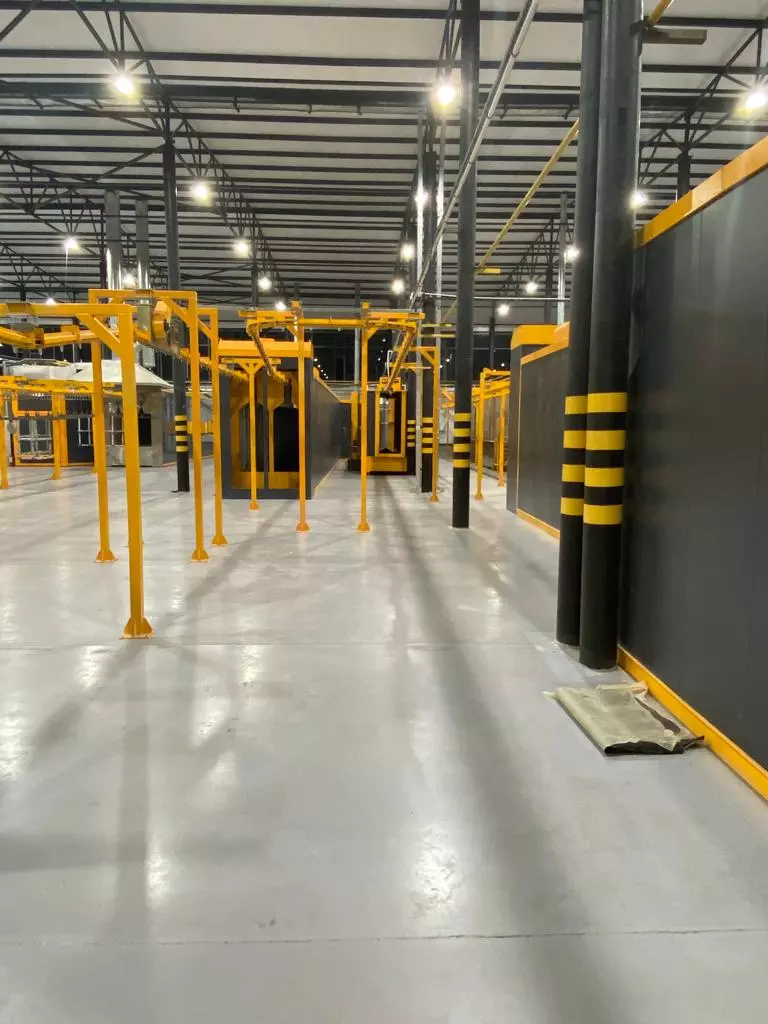

Fluidized Bed Powder coating equipment manufacturing

Fluidized bed powder coating equipment is a specialized technology used for applying a dry powder coating to a substrate, typically metal parts. The key difference from traditional liquid coatings is that in powder coating, the coating material is applied as a powder, which is then melted and cured to form a solid, durable finish. Fluidized bed powder coating utilizes the same basic principle of fluidization, where powder particles are suspended in a stream of air, ensuring uniform coating coverage over the surface of the part.

How Fluidized Bed Powder Coating Works

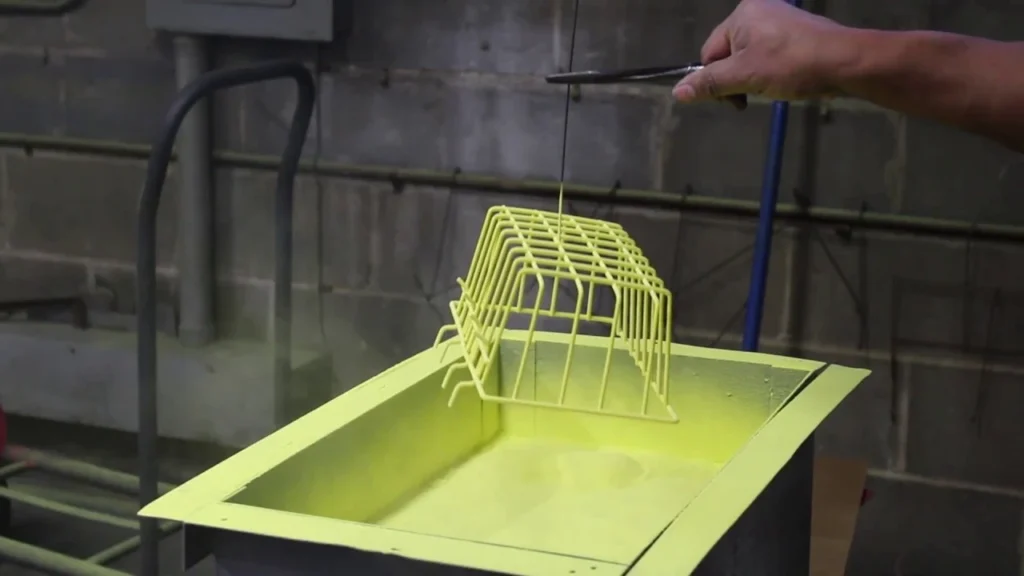

- Fluidization Process: The powder is placed in a chamber where an upward airflow (usually via a perforated plate or bed) is used to suspend the powder particles. As the particles become suspended, they take on a fluid-like behavior, which allows them to be evenly distributed and applied to the surface of the workpieces. This is similar to fluidized bed coating used in other industries, but in this case, the aim is to coat solid parts with a dry powder.

- Coating Application: The part to be coated is dipped into the fluidized bed. As the part enters the chamber, the suspended powder adheres to the heated surface. The part may be pre-heated before dipping to ensure that the powder sticks effectively, creating a uniform coating.

- Curing: After the part is coated with the powder, it typically undergoes a curing process. The coated part is heated in an oven where the powder melts and bonds to the substrate. The temperature and time of curing depend on the type of powder being used but typically range between 160°C and 200°C for 10–30 minutes.

Key Components of Fluidized Bed Powder Coating Equipment

- Fluidized Bed Chamber: The chamber contains a perforated plate or mesh, which allows the air to flow upward, suspending the powder particles. The part to be coated is immersed into this fluidized bed of powder, and it picks up a uniform layer of powder coating.

- Air Supply System: This system provides the airflow that suspends the powder in the fluidized bed. Air is typically filtered and regulated to ensure the correct airflow and fluidization of the powder.

- Powder Storage and Delivery: The powder is stored in a hopper and is often equipped with a vibration mechanism to prevent clumping and ensure consistent flow. Powder is delivered into the fluidized bed chamber, where it is aerated by the airflow.

- Temperature Control System: The parts are often preheated before dipping, and a curing oven or infrared heaters are used after coating to melt and bond the powder to the surface.

- Exhaust System: A system that removes excess air and ensures that no unwanted powder particles are released into the environment, maintaining a clean workspace and preventing contamination.

- Control System: Modern fluidized bed powder coating equipment comes with an automated control system to monitor and adjust temperature, air pressure, flow rates, and timing, ensuring consistent application and curing.

Advantages of Fluidized Bed Powder Coating

- Durability: Powder coatings provide excellent resistance to abrasion, corrosion, and weathering. The coating typically has a thicker and more uniform layer compared to liquid coatings, making it more durable and long-lasting.

- Environmentally Friendly: Unlike liquid coatings, which may contain volatile organic compounds (VOCs) and solvents, powder coatings are free from these harmful chemicals. There is also little to no waste, as excess powder can be reclaimed and reused.

- Uniform Coating: The fluidized bed allows for a consistent and uniform coating across all surface areas of the part, even complex geometries, ensuring high-quality finishes.

- No Drips or Runs: Since the coating is applied as a powder, there is no risk of drips, runs, or sags, which can sometimes occur with liquid coatings.

Applications of Fluidized Bed Powder Coating

- Metal Parts: Commonly used for coating metal parts in industries such as automotive, appliances, and manufacturing. The equipment is especially useful for large or irregularly shaped parts, such as automotive components, that are difficult to coat uniformly using traditional methods.

- Corrosion Resistance: Fluidized bed coating is particularly valuable for applications where parts need a durable, corrosion-resistant finish, such as in industrial equipment, pipelines, and outdoor fixtures.

- Heat-Sensitive Materials: For applications where a high level of temperature resistance is required, fluidized bed powder coating can be used with powders designed to withstand extreme temperatures.

- Rework and Repair: It can also be used for re-coating or repairing previously coated parts by reapplying the powder and curing it to restore the finish.

Advantages Over Other Coating Methods

- No Solvents: Unlike liquid coatings that often require solvents, powder coating uses no liquid solvents, making the process more environmentally friendly and reducing health risks associated with solvent exposure.

- Thicker Coatings: Fluidized bed coating can create thicker coatings in a single dip, which is ideal for certain applications such as heavy-duty equipment parts.

- Low Operational Costs: The powder can be reclaimed and reused, reducing material costs over time. Additionally, energy consumption may be lower compared to spray powder coating, as the parts are dipped directly into the fluidized bed.

Challenges and Considerations

- Part Preheating: Preheating the parts is crucial for successful fluidized bed powder coating, especially for parts with complex geometries or large surface areas. The parts must be heated to the correct temperature to ensure proper powder adhesion.

- Powder Type and Composition: The selection of powder is important. Different powders (such as epoxy, polyester, or hybrid blends) have different curing requirements and environmental characteristics, such as resistance to chemicals, UV degradation, and temperature.

- Complex Geometry: While fluidized bed coating works well for a wide variety of shapes, very small or intricate parts may present challenges due to powder distribution issues. Careful selection of the fluidized bed’s air pressure and powder type can help mitigate this.

Fluidized Bed vs. Spray Powder Coating

While both fluidized bed and spray powder coating are effective methods for applying powder coatings, they differ in the way the powder is applied and the type of parts they are suited for.

- Fluidized Bed Powder Coating: Ideal for large, simple parts or batches of small parts that can be dipped in the bed. It is better for thicker coatings and is well-suited for applications like heavy-duty industrial equipment or metal components.

- Spray Powder Coating: Involves spraying a charged powder onto the substrate, typically using an electrostatic charge to attract the powder. This method is better for complex geometries or parts that cannot be easily dipped into a fluidized bed. It also offers more precise control over the thickness of the coating.

Conclusion

Fluidized bed powder coating equipment is a reliable, efficient, and environmentally friendly method for applying a durable and uniform coating to parts, especially metal substrates. Its application spans industries such as automotive, aerospace, and manufacturing, where long-lasting, corrosion-resistant finishes are required. While it may not be the most suitable choice for highly intricate or small parts, its benefits of uniformity, environmental friendliness, and the ability to apply thicker coatings make it an excellent option for many industrial applications.

Fluidized bed powder coating equipment manufacturing involves a sophisticated process to design and produce machines capable of coating a variety of substrates, typically metal, with a powder coating. These machines use the principle of fluidization, where powdered coating material is suspended in an upward flow of air, creating a “fluid-like” effect. This allows the powder to evenly coat the surface of parts that are then cured in a high-temperature oven. The key benefits of fluidized bed powder coating include its ability to apply thick, durable coatings efficiently, without the need for solvents, which makes it an environmentally friendly option compared to traditional liquid coating methods. This process is particularly effective for coating parts that are large, have simple geometries, or are prone to corrosion. The typical industries that benefit from fluidized bed powder coating include automotive, industrial equipment manufacturing, and even some consumer goods like appliances. Fluidized bed coating is often used in situations where high durability and corrosion resistance are critical.

In manufacturing fluidized bed powder coating equipment, a primary challenge is ensuring precise airflow control and uniform powder distribution. The equipment is designed with a chamber where the powder is introduced and suspended by an air supply system. The powder is kept fluidized in the chamber by a combination of air pressure, temperature control, and mechanical vibration to keep the powder from clumping together. This powder is then applied to the parts that are dipped into the fluidized bed. Parts that are to be coated are preheated, which helps the powder adhere more effectively when they are immersed into the bed.

Once coated, the parts are moved into a curing oven where the powder melts and forms a solid, uniform coating on the part. The curing process generally requires heat in the range of 160°C to 200°C, with a curing time of 10 to 30 minutes depending on the size and type of powder used. The temperature and curing time need to be carefully controlled to ensure the coating is sufficiently hardened and bonded to the substrate.

The equipment itself includes several key components such as the fluidized bed chamber, air supply system, powder storage and delivery systems, temperature control systems, and curing ovens. The chamber is typically fitted with a perforated plate that allows air to be blown upward, keeping the powder suspended. The air supply system consists of a fan, filter, and air regulator to ensure a consistent flow and pressure of air. The powder is stored in hoppers and often features mechanisms to prevent clumping, such as vibrators that help maintain a steady flow of powder into the chamber.

Powder storage and delivery systems ensure that the powder remains consistent in flow and quality, and this often involves vibration or mechanical agitation to prevent powder from settling or becoming compacted. The temperature control system regulates the temperature of the air used to fluidize the powder and the temperature of the preheated part. A reliable temperature control system is crucial for maintaining the consistency of the coating and ensuring that parts are adequately preheated before they enter the fluidized bed. A proper exhaust system is also crucial to remove excess powder and prevent contamination of the workspace.

A significant advantage of fluidized bed powder coating equipment is its ability to provide thicker coatings in a single application, which makes it ideal for parts that need a robust finish to protect against wear and corrosion. The process itself is highly efficient, as excess powder can be reclaimed and reused, which reduces material waste. This characteristic is especially beneficial in industries where cost control is important and where the coating material is expensive. Additionally, fluidized bed powder coating requires no solvents, reducing environmental impact and worker exposure to harmful chemicals, making it a more sustainable choice compared to traditional liquid coatings that may contain volatile organic compounds (VOCs).

The equipment is particularly suited for large or simple-shaped parts, such as automotive components, metal frames, and appliance parts. However, it may not be the ideal choice for parts with complex shapes or very fine details, as it can be difficult to control the powder application precisely on such parts. In these cases, spray powder coating systems may be preferred, as they provide more precise application control through electrostatic charges.

In manufacturing these fluidized bed powder coating systems, suppliers typically work closely with end-users to understand their specific coating needs and then customize the equipment to ensure it meets the necessary specifications. This may include adjusting the size of the fluidized bed chamber, optimizing airflow systems, and fine-tuning the curing process. Advanced fluidized bed coating systems may even incorporate automated controls to adjust the spray rates, airflow, and temperature in real-time, ensuring a more consistent coating result and reducing the need for manual intervention.

Finally, after the equipment is assembled and tested, manufacturers ensure that it complies with industry standards and regulations, such as safety protocols for airflow and temperature control and compliance with environmental standards. The equipment must be robust enough to handle the continuous, high-demand operation often required in industrial environments. Therefore, material selection for components like the chamber, air supply system, and curing ovens is critical for the durability and longevity of the equipment. High-performance alloys or special coatings may be used for parts exposed to extreme temperatures or wear.

Overall, fluidized bed powder coating equipment manufacturing combines engineering precision, material science, and process control to create machines that deliver durable, consistent, and environmentally friendly coatings for a wide range of applications. As industries continue to demand higher-quality finishes and more sustainable practices, the role of fluidized bed powder coating is likely to expand, with ongoing advancements in equipment design and technology.

As the demand for efficient and sustainable manufacturing processes continues to grow, the design and advancement of fluidized bed powder coating equipment is also evolving. The future of fluidized bed coating involves improvements in automation, process control, and material recovery, all of which contribute to making the process even more efficient and cost-effective.

One of the most exciting areas of development is automation. Many fluidized bed powder coating systems are now being designed with integrated automation capabilities, such as robotic handling and automated coating thickness measurement. Robots can be used to handle the parts being coated, reducing the need for manual intervention and increasing throughput. Automation also allows for better consistency and quality control, as robots can follow pre-programmed movements and ensure that each part is coated in exactly the same way, at the same speed, and under the same conditions.

Another critical advancement is the integration of real-time process control. Modern fluidized bed powder coating systems are increasingly equipped with sensors and control systems that monitor key parameters such as airflow rate, temperature, powder density, and coating thickness. These systems can automatically adjust parameters to maintain consistent coating quality. This real-time feedback not only reduces human error but also allows manufacturers to fine-tune the process, making it possible to produce high-quality coatings even at larger scales.

To further optimize the material recovery process, many fluidized bed powder coating systems now feature advanced reclaim systems. In these systems, excess powder that is not used in the coating process is collected and reused, greatly reducing material waste. The powder is often recycled through sophisticated filtration systems that ensure only clean, non-contaminated powder is reused. This is especially important in applications where the powder is costly or where environmental concerns demand that waste be minimized. These reclaim systems can significantly reduce operational costs and minimize the environmental impact of the coating process.

Additionally, energy efficiency has become a major focus in the development of fluidized bed powder coating equipment. As energy consumption plays a significant role in operating costs, many modern systems are designed to be more energy-efficient. Advances in heat recovery systems, where excess heat from the curing process is recycled, are reducing the amount of energy required to maintain consistent curing temperatures. This not only lowers energy costs but also minimizes the environmental footprint of the manufacturing process.

Material innovations also play a key role in improving the overall performance of fluidized bed powder coating systems. For example, the development of new types of powders—such as low-temperature curing powders, high-temperature-resistant powders, or powders with enhanced adhesion properties—has expanded the range of applications for fluidized bed coating. These innovations allow manufacturers to coat materials that were previously difficult to coat or to achieve new, specialized finishes, such as coatings that are both heat- and chemical-resistant.

Another area of progress is improved powder storage and handling systems. Traditional powder storage methods often involved large, static hoppers, but modern systems have been designed with more advanced features. For instance, powder storage is increasingly becoming more automated and features integrated vibration mechanisms to prevent clumping and ensure a consistent flow of powder into the fluidized bed. This increases the efficiency of the coating process and reduces downtime caused by clogged powder lines or inconsistent powder flow.

Additionally, improvements in safety have been an ongoing focus in fluidized bed powder coating equipment manufacturing. Since powders can sometimes be combustible, safety features are incorporated into equipment to mitigate these risks. Equipment now comes with advanced explosion-proof designs and better filtration systems to prevent the accumulation of flammable powders. Furthermore, better ventilation and dust extraction systems are being integrated to protect workers from inhaling harmful dust, which is especially important in industrial settings.

One of the most important considerations in fluidized bed powder coating is the selection of appropriate powders for specific applications. For example, some coatings are designed to be highly resistant to abrasion, corrosion, or UV degradation, while others may focus on providing an aesthetically pleasing finish. As industries continue to develop new materials and coatings, manufacturers of fluidized bed equipment are adapting to these needs by offering systems capable of handling a wider variety of powders, including those for specialized coatings like metallic or textured finishes.

To support a diverse range of industries, fluidized bed systems are becoming more customizable. Manufacturers are offering modular systems that can be scaled up or down depending on the needs of the business. For instance, a small shop may require a compact, bench-top unit for coating small batches, while a larger manufacturer may require an industrial system capable of handling thousands of parts per day. The flexibility of these modular systems means that manufacturers can adapt their equipment to meet specific production requirements, without being limited by the size or configuration of the system.

Finally, environmental regulations are driving the demand for more sustainable and eco-friendly fluidized bed powder coating solutions. As stricter regulations are introduced worldwide concerning emissions, waste, and VOCs (volatile organic compounds), fluidized bed coating offers an effective solution due to its solvent-free nature. Moreover, manufacturers are also focusing on reducing the environmental impact of the curing process. Instead of relying solely on traditional electric or gas-powered curing ovens, newer technologies are being explored, such as infrared and UV curing, which can reduce energy consumption and improve processing speed.

The growing trend toward green manufacturing and sustainability is pushing fluidized bed powder coating equipment manufacturers to explore new ways to reduce environmental impact, such as designing equipment with reduced energy consumption and low-emission systems. Moreover, the ability to recycle and reuse coating powders makes fluidized bed powder coating one of the more sustainable coating methods available.

In conclusion, fluidized bed powder coating equipment manufacturing is experiencing significant advancements that make the process more efficient, sustainable, and versatile. These developments are responding to the needs of various industries, from automotive to heavy-duty equipment manufacturing, and will continue to evolve as new materials, powders, and process technologies emerge. The integration of automation, real-time monitoring, improved energy efficiency, material recovery, and sustainability ensures that fluidized bed powder coating remains a leading solution in the coating industry, providing durable, high-quality finishes while minimizing environmental impact and operational costs.

The future of fluidized bed powder coating equipment manufacturing is poised to evolve further with emerging trends and technological innovations, enhancing the overall efficiency and application versatility of the process. As industries continue to push the boundaries of performance, durability, and environmental responsibility, fluidized bed powder coating systems are being developed with even greater focus on automation, precision, and sustainability.

Advanced Automation and AI Integration

Automation has been a significant driver in optimizing fluidized bed powder coating processes. The next stage of development lies in the integration of artificial intelligence (AI) and machine learning. AI can be used to predict and control variables such as coating thickness, air pressure, and curing times in real time, ensuring consistent and high-quality finishes. This is particularly useful in high-volume production settings where maintaining uniform quality across hundreds or thousands of parts is critical. Machine learning can also be employed to optimize powder use, detect anomalies in the coating process, and make adjustments without human intervention, increasing the precision of the operation.

Furthermore, robotic systems are increasingly being integrated into fluidized bed systems, particularly in larger manufacturing environments. Robots can handle the movement of parts through the system, from preheating to powder coating to curing, all while ensuring minimal human involvement. This not only improves speed and reduces the risk of human error but also ensures safer working conditions, particularly in environments where powder handling may expose workers to hazardous materials or dust.

3D Printing and Fluidized Bed Powder Coating

One of the emerging trends that could reshape fluidized bed powder coating is the synergy between 3D printing and powder coating. As 3D printing technology becomes more advanced, particularly with metal additive manufacturing, the ability to apply a fluidized bed powder coating to 3D printed parts is becoming more common. 3D printed parts can often have rough surfaces or micro-porosities that make them difficult to finish without a protective coating. Fluidized bed coating is well-suited to these challenges, as it can provide an even, high-durability coating on complex geometries, adding a protective layer that enhances the performance of 3D printed metal parts. The combination of 3D printing and fluidized bed powder coating is especially valuable in industries such as aerospace, automotive, and medical device manufacturing, where precision, performance, and part durability are crucial.

Enhanced Powder Technologies

The continuous development of powder materials is one of the key drivers of change in fluidized bed coating. New powders with improved properties—such as nano-coatings, powders with embedded antimicrobial properties, or coatings that offer enhanced UV and heat resistance—are being developed for specific applications. For example, powders that can cure at lower temperatures allow manufacturers to coat heat-sensitive materials or reduce the energy required for curing. The inclusion of functional additives in powder formulations, such as conductive, anti-corrosion, or anti-fingerprint agents, enhances the versatility of fluidized bed powder coating for highly specialized applications, particularly in electronics and high-tech manufacturing sectors.

Hybrid powder systems, combining different powder types to take advantage of multiple performance characteristics, are also becoming more common. These hybrid powders can offer enhanced physical properties, such as increased impact resistance or flexibility, while maintaining the aesthetic qualities of a smooth, glossy finish.

Smart Powder Recovery Systems

As environmental concerns grow, the recycling and recovery of powder materials is becoming more important. Advanced powder recovery systems are designed to maximize the reuse of excess powder, reducing material waste and cutting costs. New vacuum recovery systems and automated sieving techniques have been developed to reclaim powder that has been removed from parts and filter out contaminants, ensuring that only clean powder is reused. These innovations make it possible to significantly reduce the amount of wasted powder, improving both cost-effectiveness and sustainability. Moreover, the integration of digital sensors can monitor powder quality during recovery, ensuring that the reclaimed powder meets the necessary specifications for reuse.

Sustainability and Energy Efficiency

The push toward green manufacturing continues to be a driving factor in the development of fluidized bed powder coating systems. Manufacturers are constantly looking for ways to reduce energy consumption and minimize waste in the powder coating process. Advances in energy-efficient curing ovens, which use technologies like infrared curing, are becoming more widespread. Infrared heating is more efficient because it directly heats the part rather than the surrounding air, reducing overall energy consumption and speeding up the curing process.

Additionally, the development of low-energy fluidized bed systems is aimed at reducing the amount of electricity required for powder fluidization. By optimizing the airflow and pressure control, manufacturers are able to minimize energy consumption while maintaining the coating quality and speed. The use of sustainable powders—such as those that are biodegradable or have a lower carbon footprint—is also gaining traction, ensuring that fluidized bed powder coating aligns with broader sustainability goals.

Globalization and Customization

As global supply chains continue to expand, the demand for customizable fluidized bed coating systems that can cater to different regional needs is increasing. Equipment manufacturers are focusing on offering modular designs that allow for quick adjustments and scalability. These modular systems can be easily upgraded or adjusted based on specific customer requirements, whether for changes in production volume, coating types, or part sizes.

Customization also extends to regional powder formulations, which are tailored to local environmental conditions. For example, manufacturers in areas with high humidity may require coatings that offer enhanced moisture resistance, while those in high-temperature regions may need coatings that are more heat-resistant. By offering equipment that can accommodate these specific needs, fluidized bed powder coating manufacturers are better able to serve diverse markets worldwide.

Increased Focus on Quality Control

With the increasing complexity of parts and coatings, manufacturers of fluidized bed powder coating equipment are focusing more on precision and quality control systems. The use of digital platforms that can track every aspect of the coating process—airflow, powder flow rate, part movement, temperature, curing time, and thickness—helps ensure consistent quality across all parts. These digital solutions can also provide real-time data, allowing for immediate adjustments to be made to the coating process if needed, reducing downtime and improving operational efficiency.

Vision-based inspection systems, integrated into coating lines, can automatically detect defects in coatings, such as thin spots, excessive coating, or uneven coverage. This is particularly useful in industries where even minor defects can be costly, such as aerospace or electronics.

Collaboration Across Industries

Finally, the future of fluidized bed powder coating will likely involve greater collaboration across industries. As the need for more specialized coatings and equipment grows, manufacturers of fluidized bed coating systems are increasingly working alongside material suppliers, industry researchers, and end-users to develop coatings that meet specific performance requirements. For example, aerospace companies may partner with coating equipment manufacturers to create coatings that provide both corrosion resistance and weight savings, while automotive manufacturers might focus on developing coatings that provide both a high-quality aesthetic finish and superior scratch resistance.

The ongoing collaboration across sectors will ensure that fluidized bed powder coating continues to meet the ever-changing demands of modern manufacturing, delivering high-quality, durable finishes in an environmentally responsible manner.

In conclusion, the fluidized bed powder coating industry is evolving with rapid technological advancements aimed at improving efficiency, sustainability, and quality. From automation and AI integration to the development of new powder materials and energy-efficient systems, these innovations are setting the stage for a more advanced and eco-friendly future in coating technology. Whether for automotive, aerospace, or consumer goods manufacturing, fluidized bed powder coating is adapting to meet the needs of diverse industries while also addressing global challenges such as sustainability and energy efficiency.

As the fluidized bed powder coating industry continues to advance, several emerging trends and innovations are shaping its future trajectory. These developments will not only impact the operational aspects of fluidized bed coating but also expand its applications across a variety of sectors. Let’s explore some of these future directions.

Emerging Coating Technologies

The integration of nanotechnology in fluidized bed powder coatings is one of the most exciting areas of development. Nanomaterials, due to their unique properties, offer a significant enhancement in the performance of coatings. For instance, nanocoatings can provide increased hardness, enhanced corrosion resistance, and better wear resistance compared to conventional coatings. These properties make nanotech powder coatings ideal for demanding applications in industries such as aerospace, automotive, and military manufacturing.

Further, self-healing coatings are being explored for fluidized bed systems. These coatings can automatically repair themselves when damaged, greatly extending the lifespan of coated parts. This technology is particularly useful for parts exposed to extreme environmental conditions or wear, such as in offshore oil rigs, transportation, and heavy machinery.

Graphene-based coatings, known for their strength, flexibility, and conductivity, are gaining traction in fluidized bed coating systems. Graphene can provide coatings that are lightweight yet incredibly strong, offering enhanced protection against corrosion, temperature extremes, and physical damage. These advanced materials are especially promising in industries where high performance and durability are critical, such as in electronics and battery manufacturing.

Digitalization and the Internet of Things (IoT)

Another key trend in fluidized bed powder coating equipment manufacturing is the increasing role of digitalization and IoT (Internet of Things). IoT-enabled coating equipment allows manufacturers to gather vast amounts of data from their systems, providing insights into every aspect of the coating process. Sensors embedded in fluidized bed systems can monitor variables like powder density, air velocity, temperature, and humidity. These sensors communicate in real time with a centralized control system, enabling automatic adjustments and providing predictive analytics to prevent downtime before it occurs.

The integration of cloud computing allows for the storage and analysis of large datasets from multiple coating lines, enabling manufacturers to optimize processes across entire plants. This enables manufacturers to run predictive maintenance schedules, forecast the need for repairs or replacements, and continuously fine-tune the coating process. In addition to improving performance, these digital tools help manufacturers comply with regulatory standards by providing traceability of the coating process, which can be critical for quality assurance in certain industries such as aerospace, automotive, and food manufacturing.

Eco-Friendly Powder Coatings

As sustainability continues to be a driving force in manufacturing, there is a growing emphasis on eco-friendly powder coatings. Manufacturers are working on developing coatings that not only perform well but also minimize environmental impact throughout their lifecycle. This includes reducing the energy consumption during curing, developing coatings made from renewable or non-toxic materials, and using biodegradable powders.

The shift towards water-based powder coatings is one of the significant eco-friendly innovations. Traditional powder coatings often rely on petroleum-based chemicals, but water-based alternatives are being developed to reduce the environmental footprint of the powder coating process. These water-based coatings are not only less harmful but also contribute to reducing the volatility of the overall production process. Waterborne powder coatings can be designed to perform at high levels while offering low environmental impact, making them an excellent choice for a wide range of applications.

Recyclability of both the powder itself and the coated parts is another critical consideration in the push for more sustainable manufacturing practices. Efforts to improve the end-of-life recyclability of coated products will reduce waste and contribute to the circular economy, where materials are reused and recycled rather than discarded. Advances in waste management systems in fluidized bed coating equipment are helping reduce the disposal of powder waste, while also enabling more efficient reclamation and reuse of powder materials.

Robotics and Additive Manufacturing in Coating

Robotics is not just revolutionizing the handling of parts through the coating process but also opening up possibilities for additive manufacturing (AM) and 3D printing to be integrated into the powder coating process. In industries like automotive and aerospace, where parts often have complex geometries or customized features, the ability to 3D print metal or plastic parts and then coat them using fluidized bed powder coating systems presents numerous advantages.

The combination of 3D printing with fluidized bed powder coating offers manufacturers the flexibility to create highly detailed or complex parts with tailored coatings. For example, 3D printed parts could be designed to have hollow sections, intricate patterns, or unusual shapes, which are then uniformly coated with powder to ensure durability and performance. Additive manufacturing also allows for the production of low-volume, highly specialized parts, reducing waste and inventory costs while still benefiting from the protective and aesthetic qualities of powder coatings.

Moreover, robotic arms are increasingly being used to handle these 3D-printed parts through fluidized bed coating processes. The precision of robotics allows for better control over the part positioning, ensuring uniform coating even on intricate designs. Robotic arms also improve efficiency by handling high-mix, low-volume runs, which is common in industries like prototyping and aerospace, where custom parts are often required.

Global Trends and Customization

As manufacturers continue to serve global markets, the need for customizable coating solutions grows. Manufacturers are increasingly focusing on flexible fluidized bed powder coating systems that can be adapted to local regulations, customer preferences, and product specifications. For instance, regions with extreme temperatures may require powder coatings that provide enhanced thermal protection, while coastal areas may require coatings with advanced corrosion resistance due to exposure to saltwater.

Additionally, local supply chains and regional manufacturing needs will play a larger role in shaping fluidized bed powder coating equipment. For example, some regions may prioritize equipment that can handle specific types of coatings or that comply with strict environmental regulations. Manufacturers will need to offer more modular systems that can be quickly adjusted or reconfigured to meet regional demands. The ability to produce coating equipment that can be tailored to a specific market will be a key competitive advantage in the global marketplace.

Consumer Demand for Aesthetic Finishes

With an increasing focus on aesthetics, particularly in consumer-facing industries such as automotive, electronics, and furniture, the demand for high-quality, visually appealing coatings is on the rise. Manufacturers are increasingly relying on fluidized bed powder coating systems to deliver smooth, uniform, and aesthetically pleasing finishes. Innovations in this area include the use of textured and metallic coatings that give products a distinctive look and feel while providing the durability expected from powder coatings.

High-performance clear coatings are also gaining popularity, particularly in applications like automotive wheels and consumer electronics, where the coating needs to provide a gloss finish without compromising the substrate’s performance. As demand for more complex aesthetic finishes rises, fluidized bed powder coating equipment manufacturers will need to continuously innovate to offer customers a broad range of surface finishes, including matte, gloss, and satin effects.

Future Challenges and Opportunities

Despite the advancements, several challenges remain for the future of fluidized bed powder coating. These include the need for greater precision in powder application for intricate parts, addressing safety risks associated with handling certain types of powders, and reducing the cost of advanced powders that can be prohibitively expensive for some manufacturers.

However, these challenges present opportunities for further innovation. Research into advanced coating materials, more precise powder application technologies, and safety advancements will ensure that fluidized bed coating remains competitive. Additionally, as global manufacturing continues to evolve, the demand for customized, sustainable, and high-performance coatings will continue to drive the development of fluidized bed powder coating equipment.

In conclusion, the fluidized bed powder coating industry is entering an era of rapid innovation, driven by technological advancements, automation, sustainability initiatives, and growing consumer demand for higher-quality and more durable finishes. As these trends continue to unfold, the future of fluidized bed powder coating promises more efficient, flexible, and environmentally responsible solutions, capable of meeting the diverse and ever-evolving needs of manufacturers worldwide.

Fluidized bed powder coating machine

A fluidized bed powder coating machine is a specialized piece of equipment used in the powder coating process, where a dry powder is applied to parts or substrates to create a durable and uniform finish. Unlike traditional spray coating, fluidized bed coating involves a bed of powder suspended in a stream of air, which helps to coat the parts. The fluidized bed process is particularly well-suited for coating metal components, especially those that are complex in shape or have intricate designs. Here’s an overview of how these machines work and their key components:

How Fluidized Bed Powder Coating Works

- Fluidized Bed: The key feature of the system is the fluidized bed, which is a container that holds the powder material. The powder is usually composed of thermosetting resins that will melt and cure when exposed to heat. The bed of powder is kept suspended by an upward stream of air supplied through the bed’s bottom. This makes the powder behave like a liquid, allowing it to coat objects evenly.

- Heating the Part: The part to be coated is typically preheated in an oven before being immersed in the fluidized bed. Preheating ensures that the powder adheres better to the surface. The part is usually heated to a temperature where the powder can easily melt and bond.

- Coating: When the preheated part is dipped or inserted into the fluidized bed, the fine powder particles attach themselves to the surface of the part due to electrostatic attraction and thermal bonding. The part is then gently removed from the fluidized bed, leaving a uniform coating on its surface.

- Curing: After coating, the part is typically placed in a curing oven. The heat causes the powder to melt, flow, and fuse into a smooth, durable, and hard finish. The curing process solidifies the coating, giving it the final desired characteristics such as toughness, resistance to corrosion, and color.

Key Components of a Fluidized Bed Powder Coating Machine

- Fluidized Bed Container: This is the part of the system where the powder is kept in suspension. The container is usually equipped with an air distribution plate or screen at the bottom to evenly distribute the airflow across the powder bed. The right air velocity is critical to maintaining an even fluidization of the powder.

- Air Supply System: The air supply system forces air through the fluidized bed, suspending the powder and allowing it to behave like a liquid. This air supply is typically controlled by a compressor, and adjustments to the airflow can control the density of the powder bed and its fluidization characteristics.

- Powder Material: The powder material used in fluidized bed coating is typically a thermosetting polymer, which melts and fuses upon heating. Common powders include epoxy, polyester, and hybrid formulations, depending on the application and desired properties such as corrosion resistance, hardness, and appearance.

- Preheating Oven: A preheating oven is used to bring the parts to the desired temperature before they are coated. The temperature of the parts typically ranges between 180–200°C (350–400°F) before immersion in the fluidized bed. Preheating is necessary for proper adhesion and to ensure an even coating.

- Curing Oven: After coating, the part must be cured in a separate oven. This oven maintains a specific temperature for a set period to allow the powder to fully melt, flow, and bond to the surface, creating a durable and solid finish.

- Control System: Modern fluidized bed powder coating machines are equipped with automated control systems that regulate the airflow, temperature, and timing of various processes to ensure consistency and quality. These systems allow for adjustments based on the size, type, and material of the parts being coated, as well as the type of powder used.

Advantages of Fluidized Bed Powder Coating

- Uniform Coating: The fluidized bed system ensures that powder is evenly applied to the surface of the parts, providing a consistent finish even on complex geometries.

- No Overspray: Unlike spray coating, fluidized bed coating minimizes the loss of powder due to overspray. This leads to better material utilization and reduced waste.

- Durability: Powder coatings are generally more durable than liquid coatings. Fluidized bed coating is particularly beneficial for creating tough, abrasion-resistant finishes.

- Low Environmental Impact: Fluidized bed coating does not require solvents, which means no harmful volatile organic compounds (VOCs) are emitted during the process, making it more environmentally friendly compared to conventional liquid coatings.

- No Need for Chemical Substrates: Parts do not need to be chemically treated before coating, as the powder coating will naturally adhere to properly prepared or preheated metal surfaces.

Applications of Fluidized Bed Powder Coating

Fluidized bed powder coating machines are used across many industries due to their ability to provide high-quality, durable finishes. Some common applications include:

- Automotive: For coating parts such as engine components, wheels, and chassis parts.

- Aerospace: For coating high-performance parts exposed to extreme conditions.

- Furniture: For creating scratch- and corrosion-resistant finishes on metal furniture.

- Consumer Goods: For coating items like home appliances, garden equipment, and tools.

- Industrial Equipment: For coating parts exposed to heavy wear, including machinery components and frames.

- Architectural Coating: Used for exterior applications such as coatings on architectural metal frames, gates, and other structural components exposed to the elements.

Types of Fluidized Bed Powder Coating Machines

- Standard Fluidized Bed Systems: These are the traditional machines with a simple fluidized bed setup that works by immersing preheated parts directly into the bed of powder. They are ideal for low-volume, high-quality coating applications.

- Automated Fluidized Bed Systems: For high-volume production environments, automated fluidized bed systems can handle parts with minimal human intervention. These systems are often integrated with robotic arms or conveyors for continuous part movement, reducing labor costs and increasing throughput.

- Batch Systems: These machines are designed for processing small to medium-sized batches of parts. They are ideal for companies that need flexibility in handling different part sizes and types.

- Custom Fluidized Bed Systems: Some manufacturers offer custom fluidized bed coating machines designed for specialized applications, such as those involving unique powder formulations or specific process requirements. These systems may include advanced temperature control, dust collection systems, or specialty curing ovens.

Considerations When Selecting a Fluidized Bed Powder Coating Machine

- Part Size and Shape: Consider the size and complexity of the parts being coated. Some machines are better suited for smaller, more intricate components, while others are designed for larger, bulkier parts.

- Powder Type: The choice of powder is important for achieving the desired finish. Different powders have different properties in terms of curing temperature, flexibility, and appearance. Make sure the machine is compatible with the type of powder you plan to use.

- Production Volume: For high-volume production, look for machines that offer automation, precision, and consistent quality. Automated fluidized bed systems may be needed for high-throughput environments.

- Environmental Considerations: Consider the environmental impact, especially in terms of powder waste. Fluidized bed systems are more efficient in powder use, but the overall design should also incorporate waste reduction features like reclaim systems or air filtration.

Maintenance of Fluidized Bed Powder Coating Machines

To maintain the efficiency and effectiveness of a fluidized bed powder coating machine, regular maintenance is required:

- Cleaning: Regular cleaning of the fluidized bed container and air distribution system is essential to prevent powder buildup and clogging.

- Airflow Inspection: The airflow should be checked regularly to ensure uniform powder suspension and consistent coating. Over time, airflow may need adjustments due to wear or changes in the system.

- Powder Quality Control: Monitoring and maintaining the quality of the powder material is crucial. Old or contaminated powder may not adhere well and can result in defects in the coating.

- Inspection of Heating Systems: Preheating and curing ovens should be inspected regularly to ensure proper temperature control and uniform heating.

In summary, fluidized bed powder coating machines are an effective solution for applying uniform, durable, and environmentally friendly coatings to a wide range of parts. These machines are especially useful in industries that require high-quality finishes on complex parts or in high-volume production environments. By selecting the right system and regularly maintaining it, manufacturers can ensure optimal performance and consistent coating quality.

Fluidized bed powder coating machines are specialized pieces of equipment used in the application of dry powder coatings to parts or substrates. The fluidized bed coating process works by suspending powder particles in a stream of air, allowing them to behave like a liquid. The process involves several stages, including preheating the part to be coated, immersing it into the fluidized bed to apply the powder, and then curing the coated part in an oven to achieve a durable and uniform finish.

In a typical fluidized bed system, the powder material, usually composed of thermosetting resins, is contained in a bed that is kept in suspension by a controlled flow of air. This is done using an air distribution plate or screen at the bottom of the bed to ensure even airflow throughout the powder. The preheated part is immersed into this bed, and the powder adheres to the surface due to electrostatic attraction, which helps in forming a uniform layer.

After the coating has been applied, the part is removed and placed into a curing oven, where heat causes the powder to melt and fuse together, creating a smooth, durable, and hard finish. The part is left in the oven for a specified time at a controlled temperature, allowing the coating to solidify and bond to the substrate. The curing process also ensures that the final coating exhibits high-performance characteristics like resistance to corrosion, wear, and impacts.

These machines have several key components that work together to ensure the coating process is efficient and high-quality. The fluidized bed container holds the powder in suspension, the air supply system controls the airflow, and the preheating oven ensures the part’s surface is at the right temperature for proper powder adhesion. The curing oven is crucial for completing the powder coating process, ensuring the powder bonds and forms a solid, durable layer. Additionally, modern machines may include automated control systems that regulate variables such as temperature, airflow, and curing time, allowing for precision and consistency.

Fluidized bed powder coating offers several advantages over other coating methods. One of the primary benefits is the uniform application of the coating, even on parts with complex geometries or intricate shapes. Since the process minimizes overspray, it results in better powder utilization and less waste. The coating produced is highly durable, resistant to corrosion, and can be applied in various textures and finishes, from matte to gloss. Furthermore, fluidized bed coating is environmentally friendly since it does not require solvents or produce volatile organic compounds (VOCs), making it a more sustainable option than traditional liquid coatings.

These systems are widely used in industries like automotive, aerospace, and industrial manufacturing, where parts need to withstand harsh conditions and require robust, long-lasting coatings. The ability to coat parts in various sizes and shapes makes fluidized bed coating particularly versatile, and the process is suitable for both small and large production runs. For high-volume production, automated systems with robotic arms or conveyor belts may be incorporated to handle parts with minimal human intervention.

Customization is also a significant advantage of fluidized bed powder coating machines. Different powder formulations, such as epoxy, polyester, or hybrid coatings, can be used to meet specific application requirements, including performance characteristics like thermal resistance, impact resistance, or decorative appearance. Additionally, the system can be adapted to local environmental regulations and customer preferences, providing flexibility for manufacturers serving diverse markets.