Manual Powder Coating Plant: Powder coating has become a cornerstone in the industrial painting and coating sector, offering a durable and high-quality finish that is both environmentally friendly and cost-effective. The technology behind powder coating machinery and equipment has evolved significantly, providing manufacturers with a variety of options to enhance their production processes. Whether in automotive, aerospace, or consumer goods manufacturing, the application of powder coating systems is widespread and continues to grow as industries seek more efficient and sustainable finishing methods.

Powder coating is a dry finishing process that involves the application of finely ground particles of pigment and resin onto a surface. The coated object is then heated, causing the powder to melt and form a smooth, durable, and uniform finish. This process is different from traditional liquid painting methods, where solvents are used, leading to higher levels of waste and environmental concerns. With powder coating, there are minimal emissions of volatile organic compounds (VOCs), making it an environmentally friendly alternative.

The industrial landscape has seen a growing demand for powder coating machinery, driven by the need for more durable finishes and faster production times. The benefits of powder coating include superior corrosion resistance, a wide range of colors and textures, and a finish that is more resistant to chipping, scratching, and fading. These advantages are crucial in industries where product durability and aesthetics are critical.

Introduction to Powder Coating Machinery and Equipment

Powder coating has revolutionized the way industries approach finishing processes. Traditionally, liquid paints were the standard, but they posed numerous challenges, including prolonged drying times, susceptibility to runs and sags, and the environmental impact of VOCs. Powder coating, on the other hand, offers a solution to these issues, providing a high-quality finish that is both durable and eco-friendly.

One of the most significant advantages of powder coating is its application versatility. Industries ranging from automotive to consumer electronics have adopted powder coating systems due to their ability to provide a consistent and reliable finish. For example, in the automotive industry, powder coating is used extensively for components such as wheels, engine parts, and chassis. The process not only ensures a durable and aesthetic finish but also enhances the longevity of the components by providing superior resistance to corrosion and wear.

In the construction and architectural sectors, powder coating is favored for its ability to produce vibrant, long-lasting finishes on metal structures, including aluminum profiles used in windows and doors. The process is particularly beneficial for exterior applications, where materials are exposed to harsh weather conditions. The robustness of powder coating ensures that the finished products can withstand UV radiation, moisture, and temperature fluctuations without losing their aesthetic appeal or structural integrity.

Furthermore, the electronics industry relies on powder coating for both functional and decorative purposes. The coating protects delicate electronic components from environmental factors such as humidity and dust, which can impair their performance. Additionally, powder coating is used to create aesthetically pleasing finishes on consumer electronics, contributing to the product’s overall appeal.

Powder coating’s importance also extends to the agricultural and heavy machinery industries, where equipment is often subjected to harsh operating conditions. The resilience of powder-coated surfaces ensures that machinery can endure the rigors of daily use without succumbing to corrosion or damage. This durability translates into reduced maintenance costs and longer service life, making powder coating an economically viable option for manufacturers.

The Role of Powder Coating Machinery

The effectiveness of powder coating largely depends on the machinery and equipment used in the process. Modern powder coating systems are designed to meet the diverse needs of different industries, offering a range of options from manual systems to fully automated lines. The selection of appropriate machinery is crucial in achieving the desired finish quality, production efficiency, and cost-effectiveness.

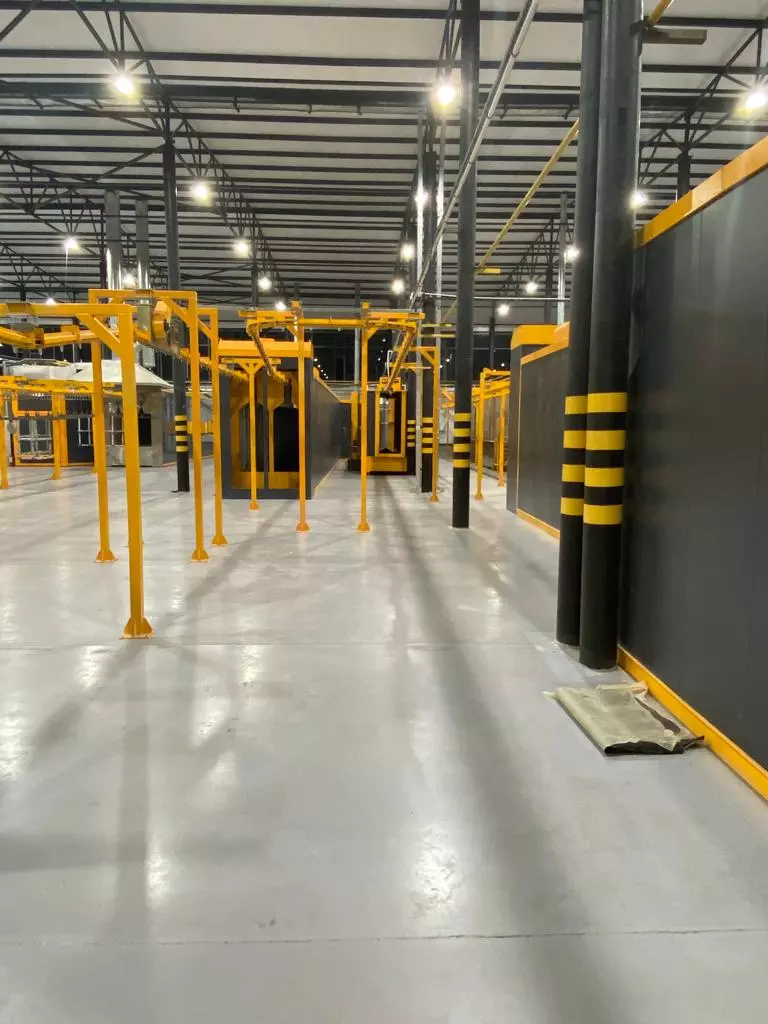

Manual powder coating systems are ideal for small-scale operations or specialized applications where precision and flexibility are required. These systems allow operators to manually control the application of powder, making them suitable for projects that involve intricate designs or low production volumes. A manual powder coating plant typically includes a powder coat applicator, a powder coating booth, and a curing oven. Despite being more labor-intensive than automated systems, manual setups offer the advantage of adaptability, enabling manufacturers to cater to custom orders and unique requirements.

On the other hand, automated powder coating systems are designed for high-volume production environments where consistency, speed, and efficiency are paramount. These systems can be fully integrated into production lines, ensuring that every component is coated uniformly and quickly. Automated paint coating systems are equipped with advanced features such as robotic applicators, conveyor systems, and automated curing ovens, which streamline the entire coating process from start to finish. This automation reduces the need for manual intervention, minimizes errors, and increases overall throughput, making it ideal for large-scale manufacturing operations.

In addition to manual and automated systems, there are also specialized machines designed for specific coating processes. For example, calcium carbonate coating machines are used to apply protective coatings to non-metallic surfaces, while aluminum coating machines are tailored for the unique requirements of aluminum products. These specialized machines play a critical role in expanding the applicability of powder coating technology across various industries.

Overall, the development and integration of advanced powder coating machinery have been instrumental in enhancing the efficiency, quality, and sustainability of industrial finishing processes. As manufacturers continue to seek out ways to improve their operations, the demand for innovative powder coating systems and equipment is expected to grow.

Advantages of Using Powder Coating Machinery

The advantages of powder coating machinery are numerous and contribute to its widespread adoption in the industrial sector. Some of the key benefits include:

- Environmental Friendliness: Powder coating is an eco-friendly process that produces minimal waste. Unlike traditional liquid paints, which release harmful VOCs into the atmosphere, powder coatings are solvent-free, reducing the environmental impact. Additionally, oversprayed powder can be collected and reused, further minimizing waste.

- Durability and Quality: The finish provided by powder coating is exceptionally durable, resistant to chipping, scratching, and fading. This durability makes it ideal for products that need to withstand harsh conditions, such as outdoor furniture, automotive parts, and industrial machinery.

- Cost-Effectiveness: While the initial investment in powder coating machinery may be higher than traditional painting equipment, the long-term cost savings are significant. The efficiency of the process, reduced waste, and lower energy consumption contribute to overall cost reductions in the production process.

- Versatility: Powder coating machinery is versatile and can be used on a wide range of materials, including metals, plastics, and composites. This versatility makes it suitable for various industries, from automotive and aerospace to consumer electronics and construction.

- Enhanced Aesthetics: Powder coating offers a wide variety of finishes, including matte, glossy, textured, and metallic effects. The ability to achieve consistent and vibrant colors enhances the aesthetic appeal of finished products, making them more attractive to consumers.

Types of Powder Coating Systems

Manual Powder Coating Systems

Manual powder coating systems are essential for operations that require flexibility and precision. These systems are typically used in smaller production environments or for specialized applications where human oversight is crucial. A manual powder coating plant consists of several key components, including a powder coat applicator, a powder coating booth, and a curing oven.

Manual Powder Coating Plant vs. Manual Powder Coating Line: The terms “manual powder coating plant” and “manual powder coating line” are often used interchangeably, but they can refer to slightly different setups depending on the scale and complexity of the operation. A manual powder coating plant usually refers to a complete facility equipped with all necessary equipment for powder coating, from preparation to curing. This plant includes a dedicated area for surface preparation, a powder coating booth, and one or more curing ovens.

In contrast, a manual powder coating line might refer to a more streamlined setup where components are moved sequentially through different stages of the coating process. This line might involve a basic conveyor system to move parts from the coating booth to the curing oven. The primary advantage of a manual powder coating line is that it allows for a more organized workflow, even in small-scale operations.

Features of a Manual Powder Coating System: Manual powder coating systems offer several advantages that make them suitable for specific applications:

- Flexibility: Operators can adjust the powder flow and spray pattern to suit different shapes and sizes of workpieces, allowing for a high degree of customization.

- Precision: Manual application ensures that intricate or irregularly shaped objects receive an even coating, which can be challenging for automated systems.

- Cost-Effective for Small Batches: For small production runs or one-off projects, manual systems are more cost-effective than automated systems, which require a higher initial investment.

- Easy Maintenance: Manual systems generally have fewer components than automated systems, making them easier and less expensive to maintain.

Manual powder coating systems are often used in industries such as custom automotive parts, metal fabrication, and smaller manufacturing operations where the volume does not justify the investment in full automation.

Automated Powder Coating Systems

Automated powder coating systems represent the pinnacle of efficiency in the coating process. These systems are designed for high-volume production environments where consistency, speed, and minimal human intervention are paramount. Automated systems can handle complex operations, ensuring that each part receives a uniform coating.

Introduction to Automated Paint Coating: Automated paint coating systems integrate several advanced technologies to streamline the coating process. These systems are typically equipped with robotic arms or automated spray guns that apply the powder coating to the workpieces as they move along a conveyor system. The entire process, from surface preparation to powder application and curing, is controlled by a centralized system, ensuring optimal conditions for each stage.

Benefits and Use Cases: Automated powder coating systems offer several significant benefits:

- High Throughput: These systems can coat large volumes of parts quickly and efficiently, making them ideal for industries with high production demands, such as automotive manufacturing and consumer goods.

- Consistency: Automated systems ensure that every part receives the same amount of coating, reducing the likelihood of defects and ensuring a consistent finish across all products.

- Reduced Labor Costs: Automation reduces the need for manual labor, lowering overall production costs while increasing efficiency.

- Integration with Existing Systems: Automated systems can be integrated into existing production lines, allowing for seamless transitions between different stages of manufacturing.

Types of Automatic Coating Processes: Automated powder coating systems can be configured to suit various types of coating processes, depending on the specific needs of the operation:

- Electrostatic Spraying: The most common method, where powder particles are charged and adhere to the grounded workpiece, ensuring an even coating.

- Fluidized Bed Coating: This process involves dipping preheated parts into a fluidized bed of powder, which melts and adheres to the surface. It’s ideal for coating heavy-duty items like metal pipes or tools.

- Hot Flocking: In this method, the part is heated before the powder is applied, which helps the powder adhere more effectively and create a thicker coating.

Automated systems are commonly used in large-scale operations, including automotive assembly lines, appliance manufacturing, and other industries where speed and consistency are critical.

Turnkey Paint Finishing Systems

Turnkey paint finishing systems are comprehensive solutions designed to provide everything a manufacturer needs to implement a powder coating process. These systems are ideal for companies looking to establish a complete powder coating operation without having to design and integrate individual components themselves.

Explanation of Turnkey Systems: A turnkey system typically includes all necessary equipment, from surface preparation units and powder coating booths to curing ovens and conveyor systems. These systems are fully assembled and tested before delivery, ensuring that they are ready to use upon installation. Turnkey solutions are designed to be user-friendly, allowing manufacturers to start production with minimal setup time.

Integration of Manual and Automated Processes: One of the significant advantages of turnkey systems is their ability to integrate both manual and automated processes. For instance, a turnkey system might include an automated powder coating line for high-volume production, along with a manual station for custom jobs or touch-ups. This flexibility allows manufacturers to handle a wide range of projects using a single system.

Advantages of Turnkey Systems:

- Reduced Setup Time: Since turnkey systems are pre-assembled and tested, installation and setup are much quicker compared to purchasing and integrating separate components.

- Cost Savings: Turnkey solutions often come at a lower cost than purchasing individual components separately, and they reduce the need for specialized installation services.

- Reliability: These systems are designed and tested as a complete unit, reducing the likelihood of compatibility issues or malfunctions.

Turnkey paint finishing systems are particularly beneficial for companies expanding their operations or entering the powder coating market for the first time. They provide a hassle-free way to establish a complete and efficient powder coating operation.

Powder Spray Machines

Powder spray machines are critical components in both manual and automated powder coating systems. These machines are responsible for applying the powder coating to the workpieces, using various methods to ensure even coverage and adhesion.

Functionality and Key Features: Powder spray machines work by electrostatically charging powder particles as they exit the spray gun. The charged particles are attracted to the grounded workpiece, where they adhere evenly. Key features of powder spray machines include:

- Adjustable Spray Patterns: The ability to adjust the spray pattern allows operators to coat parts of different shapes and sizes with precision.

- Variable Powder Flow: Operators can control the amount of powder being sprayed, which is crucial for achieving the desired coating thickness.

- Ergonomic Design: Many powder spray machines are designed with ergonomics in mind, reducing operator fatigue during prolonged use.

Differences Between Powder Paint Machine and Powder Spray Machine: While the terms “powder paint machine” and “powder spray machine” are sometimes used interchangeably, there are subtle differences. A powder spray machine specifically refers to the device that applies the powder coating, typically through an electrostatic process. On the other hand, a “powder paint machine” might refer to the entire system used in the powder coating process, including the spray machine, the booth, and the curing oven.

Powder spray machines are integral to achieving high-quality finishes in powder coating operations. They are used in various industries, from automotive manufacturing to consumer goods, and are essential for both manual and automated systems.

Key Equipment in Powder Coating

Powder Coat Applicator

The powder coat applicator is one of the most crucial components in any powder coating system. This device is responsible for the precise application of powder coating to the workpiece, ensuring a consistent and even layer. The performance of the applicator directly impacts the quality of the final finish, making it essential to choose the right applicator for the job.

Detailed Description and Types: Powder coat applicators come in various forms, depending on the specific requirements of the coating process. The two most common types are:

- Electrostatic Spray Guns: These are the most widely used applicators in powder coating. They work by charging the powder particles as they pass through the gun, which then adhere to the grounded workpiece. The electrostatic charge ensures that the powder is evenly distributed across the surface, minimizing waste and overspray.

- Tribo Guns: Unlike electrostatic spray guns, tribo guns rely on friction to charge the powder particles. As the powder moves through the gun, it rubs against the gun’s interior surfaces, gaining a charge through friction. Tribo guns are especially useful for coating objects with complex shapes, as they provide more uniform coverage in hard-to-reach areas.

Techniques for Effective Application: To achieve the best results with a powder coat applicator, operators must consider several factors:

- Proper Grounding: Ensuring that the workpiece is properly grounded is crucial for the powder to adhere effectively. Poor grounding can result in uneven coating or powder that doesn’t stick to the surface.

- Adjusting the Spray Pattern: Depending on the shape and size of the workpiece, the spray pattern of the applicator may need to be adjusted. A wider spray pattern is ideal for flat surfaces, while a narrower pattern is better for intricate or curved areas.

- Controlling the Powder Flow: Adjusting the flow of powder from the applicator is essential for achieving the desired coating thickness. Too much powder can lead to runs and sags, while too little may not provide adequate coverage.

Proper use of the powder coat applicator is essential for achieving a smooth, durable finish that meets industry standards. This equipment is used across various industries, including automotive, aerospace, and general manufacturing, where high-quality finishes are required.

Powder Coating Booths

The powder coating booth is another critical component in the powder coating process. This enclosed area is where the actual application of the powder takes place, and it is designed to contain overspray and prevent contamination of the surrounding environment. The design and functionality of the powder coating booth play a significant role in the efficiency and safety of the coating process.

Design and Functionality: Powder coating booths are designed to provide a controlled environment for the application of powder coating. They come in various sizes and configurations, depending on the specific needs of the operation. Key features of a powder coating booth include:

- Airflow Control: Proper airflow is essential in a powder coating booth to ensure that overspray is contained and doesn’t settle on the freshly coated workpiece. Most booths are equipped with a ventilation system that pulls air through filters, capturing excess powder particles and maintaining a clean workspace.

- Lighting: Good lighting is crucial for operators to see the workpiece clearly and ensure even coverage. Powder coating booths are typically equipped with bright, shadow-free lighting to illuminate the entire work area.

- Safety Features: To protect operators, powder coating booths are designed with safety features such as explosion-proof lights and switches, as well as emergency shut-off systems. These features help mitigate the risk of fire or explosion, which can occur if powder particles become suspended in the air at high concentrations.

Importance of Airflow and Safety: The airflow system in a powder coating booth is critical for both quality and safety. A well-designed airflow system ensures that overspray is efficiently captured and recycled, reducing waste and maintaining a clean environment. Additionally, proper airflow helps prevent powder buildup, which can be a fire hazard. The inclusion of a bag filter for powder coating or a powder coating filter system is essential to ensure that the extracted air is clean and free of particles before it is released back into the environment.

Safety is paramount in powder coating operations, and booths are engineered to meet strict safety standards. Operators must be trained in the correct use of the booth and the importance of maintaining the ventilation and filtration systems to prevent accidents.

Powder coating booths are used in various industries, including automotive, construction, and metal fabrication, where large or multiple parts need to be coated efficiently and safely.

Powder Coating Ovens

After the powder coating is applied, the workpiece must be cured in an oven. The powder coating oven is responsible for heating the coated parts to a specific temperature, causing the powder to melt and flow into a uniform film that adheres to the surface. This curing process is critical for achieving the final finish, and the type and design of the oven play a crucial role in the quality of the coating.

Types of Ovens (Curing Ovens, Powdercoat Oven): Powder coating ovens come in various types, each suited to different applications and production volumes. The most common types include:

- Batch Ovens: These ovens are designed to cure small batches of parts at a time. They are ideal for low-volume production or custom jobs where parts vary in size and shape. Batch ovens are typically used in manual powder coating systems.

- Conveyor Ovens: These ovens are used in automated powder coating lines where parts are continuously fed through the oven on a conveyor system. Conveyor ovens are ideal for high-volume production, as they provide consistent curing times and temperatures.

- Infrared Ovens: Infrared ovens use infrared radiation to heat the powder coating. These ovens are energy-efficient and can cure coatings faster than traditional convection ovens. They are particularly useful for parts that require quick turnaround times.

Large Curing Oven Specifications: Large curing ovens are designed for coating large or bulky items, such as automotive parts, machinery, or structural components. These ovens must be carefully designed to ensure even heat distribution across the entire workpiece, preventing hot spots or uneven curing. Key specifications to consider in large curing ovens include:

- Temperature Control: Accurate temperature control is essential to ensure that the powder coating cures properly. Large ovens must be equipped with advanced control systems that maintain consistent temperatures throughout the curing process.

- Air Circulation: Proper air circulation is critical in large ovens to ensure that heat is evenly distributed. Poor circulation can result in uneven curing, leading to defects in the final finish.

- Energy Efficiency: Large ovens can consume significant amounts of energy, so it is important to choose models that are designed for energy efficiency. Features such as insulated walls and energy-efficient burners can help reduce operating costs.

Importance of Temperature Control: Temperature control is one of the most critical factors in the curing process. If the temperature is too low, the powder may not fully cure, resulting in a soft or incomplete finish. On the other hand, if the temperature is too high, the coating can over-cure, leading to discoloration, brittleness, or other defects. Advanced ovens are equipped with precise temperature controls that allow operators to set and maintain the optimal curing temperature for each type of powder.

Powder coating ovens are essential in a wide range of industries, from automotive manufacturing to metal fabrication, where a durable and high-quality finish is required.

Conveyors in Powder Coating

Conveyor systems are integral to automated powder coating lines, where they transport parts through various stages of the coating process, from surface preparation to curing. The efficiency and design of the conveyor system play a crucial role in the overall productivity of the coating line.

Types of Conveyors (Inverted Monorail Conveyor, Paintline Conveyors): Several types of conveyors are used in powder coating, each designed to meet specific operational needs:

- Inverted Monorail Conveyor: Inverted monorail conveyors are commonly used in powder coating lines for their flexibility and efficiency. The conveyor runs below the parts, keeping the hanging workpieces stable and preventing contamination from overhead systems. This design is particularly useful for coating large or heavy parts.

- Overhead Conveyors: These conveyors are often used in automated lines where parts need to be transported through multiple stages of the coating process. Overhead conveyors can be configured in various layouts, including straight lines, loops, or custom paths, depending on the production requirements.

- Belt Conveyors: Belt conveyors are used for transporting flat or small parts that cannot be hung. These conveyors provide a smooth and continuous surface, ensuring that parts are moved efficiently through the coating line.

Role in the Coating Line Process: Conveyors are essential for ensuring that parts move seamlessly from one stage of the coating process to the next. They help maintain a consistent workflow, reducing the time between application and curing. Additionally, conveyors can be integrated with automated systems to optimize the entire production process, from loading parts onto the conveyor to removing them after curing.

Customization and Flexibility: One of the key advantages of modern conveyor systems is their ability to be customized to meet specific production needs. Manufacturers can design conveyor paths that minimize space requirements, reduce handling time, and optimize the flow of parts through the coating line. Flexibility is also important, as it allows the system to be adapted for different products or production volumes without significant changes to the setup.

Conveyors are widely used in industries that require high-volume powder coating, such as automotive manufacturing, appliance production, and metal fabrication. Their role in streamlining the coating process is essential for maintaining efficiency and reducing production costs.

Pretreatment and Cleaning Processes

Importance of Pretreatment

In the powder coating process, surface preparation, or pretreatment, is crucial for achieving a high-quality, durable finish. Without proper pretreatment, even the best powder coatings can fail to adhere properly, leading to issues such as flaking, rust, and reduced lifespan of the coated product. Pretreatment involves cleaning the surface to remove contaminants like oil, dirt, and rust, followed by applying a chemical treatment that enhances the bonding of the powder to the substrate.

Role in Ensuring Quality Powder Coating: Pretreatment serves several critical functions in the powder coating process:

- Enhanced Adhesion: Properly treated surfaces allow the powder to bond more effectively, ensuring a uniform and strong coating that resists peeling and chipping.

- Corrosion Resistance: Pretreatment processes like phosphating create a conversion coating that provides an additional layer of protection against corrosion, especially important for outdoor or high-moisture applications.

- Improved Surface Finish: By removing imperfections and contaminants, pretreatment ensures a smoother and more aesthetically pleasing finish.

Skipping or inadequately performing pretreatment can result in coatings that are susceptible to premature failure, compromising both the appearance and performance of the finished product.

Common Pretreatment Processes

Several pretreatment methods are used in powder coating, each tailored to specific materials and desired outcomes. Two of the most common processes are the Iron Phosphate Coating Process and the Zinc Phosphate Coating Process.

Iron Phosphate Coating Process: The iron phosphate coating process is widely used for steel and other ferrous metals. It involves applying a phosphate coating to the metal surface, which creates a layer of iron phosphate. This layer enhances the adhesion of the powder coating and provides basic corrosion resistance.

- Process Overview: The process typically involves cleaning the metal surface to remove oils, greases, and other contaminants, followed by applying the iron phosphate solution, which reacts with the metal to form the phosphate coating. The treated part is then rinsed and dried, ready for powder coating.

- Benefits: Iron phosphate is less expensive and easier to apply than zinc phosphate, making it a popular choice for general industrial applications where extreme corrosion resistance is not required.

Zinc Phosphate Coating Process: Zinc phosphate is used when a higher level of corrosion resistance is needed, such as in automotive or outdoor applications. It forms a heavier, more protective layer than iron phosphate, making it ideal for harsh environments.

- Process Overview: Similar to iron phosphate, the zinc phosphate process begins with cleaning the metal surface. The metal is then immersed in a zinc phosphate solution, which reacts to form a crystalline coating that adheres strongly to the metal. The process usually involves multiple stages, including rinsing and drying.

- Benefits: Zinc phosphate provides superior corrosion protection, making it suitable for parts that will be exposed to moisture, salt, or other corrosive elements. It also improves paint adhesion, ensuring that the powder coating remains intact under challenging conditions.

Comparison and Use Cases:

- Iron Phosphate: Best for applications where cost is a concern, and the environment is less demanding, such as indoor furniture or general metal fabrication.

- Zinc Phosphate: Ideal for automotive parts, outdoor furniture, and other applications where long-term durability and corrosion resistance are critical.

The choice between iron and zinc phosphate depends on the specific needs of the application, including environmental exposure, desired lifespan, and budget.

Cleaning Equipment and Processes

Proper cleaning is the first and most critical step in pretreatment. The effectiveness of the entire powder coating process depends on the thorough removal of contaminants like grease, oil, rust, and scale from the metal surface. Various cleaning methods are employed, depending on the material and the nature of the contaminants.

Overview of Powder Coating Cleaning Processes: The cleaning process typically involves several stages, including degreasing, rinsing, and sometimes abrasive cleaning. Each step is designed to remove specific types of contaminants and prepare the surface for the chemical pretreatment that follows.

- Degreasing: This step involves removing oils and greases that may have been applied during manufacturing or handling. Common degreasing methods include solvent cleaning, alkaline cleaning, and steam cleaning. Alkaline cleaners are particularly effective for removing organic contaminants and are widely used in industrial settings.

- Rinsing: After degreasing, the parts are rinsed with water to remove any residual cleaning agents. Multiple rinsing stages are often used to ensure that the surface is free of any contaminants that could interfere with the coating process.

- Abrasive Cleaning: For surfaces with rust, scale, or other stubborn contaminants, abrasive cleaning methods such as sandblasting or shot blasting may be used. These methods mechanically remove the contaminants, leaving a clean, roughened surface that improves the adhesion of the powder coating.

Cleaning Agents and Equipment Used: The choice of cleaning agents and equipment depends on the material being coated and the type of contaminants present. Some commonly used cleaning agents include:

- Alkaline Cleaners: Effective for removing organic contaminants like oils and greases. These cleaners are often used in immersion tanks or spray systems.

- Acid Cleaners: Used for removing scale, rust, and other inorganic contaminants. Acid cleaning is often followed by a neutralizing rinse to prevent any residual acid from interfering with the coating process.

- Abrasive Blasters: Equipment such as sandblasters or shot blasters is used to remove rust, scale, and other tough contaminants. These machines propel abrasive media at high speeds to clean and roughen the surface, improving coating adhesion.

Importance of Proper Cleaning: Thorough cleaning is essential for ensuring that the powder coating adheres properly to the surface. Even small amounts of contaminants can cause the coating to fail, leading to issues such as peeling, blistering, or corrosion. Investing in the right cleaning equipment and following a rigorous cleaning process is crucial for achieving a durable, high-quality finish.

In industries where long-term durability is essential, such as automotive manufacturing or outdoor metal fabrication, proper cleaning and pretreatment are critical components of the coating process.

Powder Coating Process for Various Materials

Powder Coating on Metals

Powder coating is most commonly used on metal surfaces due to its ability to provide a durable, corrosion-resistant finish that can withstand harsh environmental conditions. The process for coating metals varies slightly depending on the type of metal and the intended application.

Aluminum Profile Repainting: Aluminum is a widely used metal in industries such as construction, automotive, and electronics, where its lightweight and corrosion-resistant properties are highly valued. However, when aluminum surfaces are exposed to outdoor conditions, they can oxidize, leading to a dull appearance. Powder coating offers an effective solution for repainting aluminum profiles, restoring their appearance and enhancing their durability.

- Surface Preparation: Before applying the powder coating, the aluminum surface must be thoroughly cleaned and treated. This typically involves degreasing, followed by an etching process that removes oxidation and roughens the surface to improve powder adhesion. In some cases, a conversion coating, such as chromate or non-chromate treatment, is applied to enhance corrosion resistance.

- Powder Coating Application: The cleaned and treated aluminum profile is then coated using an electrostatic spray gun. The powder is applied evenly across the surface, ensuring full coverage. Since aluminum is a conductive material, it holds the electrostatic charge well, allowing the powder to adhere effectively.

- Curing: After the powder is applied, the aluminum profile is cured in an oven at a specific temperature and duration, depending on the type of powder used. This curing process causes the powder to melt and flow into a uniform, durable coating.

Specifics of the Powder Coating Process for Aluminum: When powder coating aluminum, it is important to consider the type of powder being used, as well as the curing conditions. Aluminum is sensitive to temperature, so curing temperatures and times must be carefully controlled to prevent warping or other damage. Additionally, some powders are specifically formulated for aluminum to enhance adhesion and provide better protection against UV radiation and corrosion.

Powder coating aluminum profiles is a common practice in industries like architecture, where window frames, doors, and curtain walls require durable, long-lasting finishes. The powder coating not only enhances the appearance of these structures but also extends their lifespan by protecting them from the elements.

Iron and Steel Powder Coating: Iron and steel are other common metals that benefit significantly from powder coating. These materials are used in a wide range of applications, from automotive components to industrial machinery, where protection against rust and corrosion is critical.

- Surface Preparation: Steel and iron require rigorous surface preparation to remove rust, scale, and other contaminants. This typically involves abrasive blasting, followed by a chemical treatment, such as the iron or zinc phosphate coating process, to enhance adhesion and corrosion resistance.

- Powder Application: The prepared steel or iron surface is coated using an electrostatic spray gun or, in some cases, a fluidized bed process, where the heated metal is dipped into a bed of powder, which melts and adheres to the surface.

- Curing: The powder-coated metal is then cured in an oven, where the powder forms a hard, protective layer that shields the metal from environmental damage.

Powder coating iron and steel is particularly important in industries such as automotive manufacturing, where parts are exposed to road salts, moisture, and extreme temperatures. The powder coating provides a robust barrier against these elements, ensuring the longevity and reliability of the coated components.

Non-Metallic Surfaces

Powder coating is not limited to metals; it can also be applied to non-metallic surfaces, although the process can be more challenging due to the different properties of these materials.

Calcium Carbonate Coating Machines: Calcium carbonate is a commonly used material in industries such as plastics, paints, and coatings, where it serves as a filler or coating material. Powder coating machines specifically designed for calcium carbonate are used to apply a thin, uniform layer of powder coating to the surface of calcium carbonate particles.

- Surface Preparation: In the case of non-metallic surfaces like calcium carbonate, surface preparation might involve preheating or chemical treatment to improve the adhesion of the powder coating.

- Powder Application: The powder is applied using specialized equipment that ensures even distribution over the surface of the calcium carbonate. The coating process must be carefully controlled to avoid agglomeration or uneven coverage.

- Curing: Since calcium carbonate cannot withstand the high temperatures used for metal curing, alternative curing methods, such as UV or infrared curing, may be employed to achieve the desired finish.

Challenges and Solutions for Non-Metal Powder Coating: Coating non-metallic surfaces, such as plastics, ceramics, or wood, presents unique challenges. Unlike metals, these materials are not conductive, making it difficult to apply powder using the traditional electrostatic method. To address this, manufacturers may use conductive primers that allow the powder to adhere to the surface, or they may use alternative powder application methods that do not rely on electrostatic attraction.

Another challenge is the thermal sensitivity of non-metals. Since these materials can warp, melt, or degrade at high temperatures, the curing process must be carefully controlled. UV or infrared curing, which operates at lower temperatures, is often used for non-metal powder coating to avoid damaging the substrate.

Powder coating non-metallic surfaces is gaining popularity in industries such as consumer electronics and furniture manufacturing, where durable, aesthetically pleasing finishes are required for products made from plastics, composites, or wood.

Special Coating Processes

In addition to standard powder coating applications, there are specialized processes designed for specific purposes or materials.

Filter Coating and Powder Paint Filter Technologies: Filters are critical components in many industrial processes, including powder coating systems. Coating filters with powder paint improves their durability, resistance to corrosion, and overall performance. Powder paint filter technologies involve applying a thin layer of powder coating to the surface of the filter, which is then cured to form a protective barrier.

- Applications: Powder-coated filters are used in a variety of settings, including HVAC systems, industrial filtration units, and even automotive filters. The powder coating extends the life of the filter by protecting it from rust, chemical exposure, and physical wear.

- Process: The filter is typically cleaned and pretreated before the powder coating is applied. The coating process can be done manually or using automated systems, depending on the size and complexity of the filter. After coating, the filter is cured in an oven to set the powder and create a durable finish.

Powder Coating Unit Manufacturer Innovations: Powder coating unit manufacturers are continually innovating to improve the efficiency, quality, and environmental impact of their equipment. Innovations include more efficient powder spray guns, advanced curing ovens that reduce energy consumption, and integrated systems that streamline the entire powder coating process.

- Energy Efficiency: Modern powder coating units are designed with energy efficiency in mind, reducing the cost and environmental impact of the coating process. This includes features such as advanced insulation in curing ovens, energy-efficient burners, and systems that recycle excess powder.

- Automation and Control: Advances in automation allow for more precise control over the powder coating process, reducing waste and ensuring consistent quality. Automated systems can monitor and adjust parameters such as powder flow, temperature, and curing time in real-time, leading to higher efficiency and reduced operator intervention.

Manufacturers across various industries are adopting these innovations to improve the quality of their powder-coated products while also reducing costs and environmental impact.

Specialized Coating Equipment

Automatic Coating Systems

Automatic coating systems represent the cutting edge of powder coating technology, designed to maximize efficiency, consistency, and throughput in industrial applications. These systems are essential for large-scale operations where manual coating is impractical due to the volume or complexity of the parts being coated.

Features of an Automatic Coating System: Automatic coating systems are equipped with advanced technologies that automate every aspect of the powder coating process, from the initial application to curing. Key features include:

- Robotic Applicators: Automatic systems often incorporate robotic arms or automated spray guns that apply powder coating with precision. These applicators can be programmed to follow specific paths, ensuring uniform coverage even on complex shapes or hard-to-reach areas.

- Integrated Conveyor Systems: Automatic coating systems typically include conveyors that move parts through the various stages of the process, including surface preparation, powder application, and curing. The conveyors are synchronized with the robotic applicators to maintain a consistent workflow.

- Real-Time Monitoring and Control: Advanced control systems monitor key parameters such as powder flow, spray patterns, temperature, and curing time in real-time. This ensures that the coating process remains consistent, reducing the risk of defects and improving overall quality.

- Energy Efficiency: Many modern automatic coating systems are designed with energy efficiency in mind, incorporating features such as low-energy curing ovens and powder recycling systems that minimize waste and reduce operating costs.

Efficiency Improvements in Production: Automatic coating systems significantly improve production efficiency by reducing the time and labor required for coating large volumes of parts. The automation of the process minimizes human error, ensuring that each part is coated to the same high standard. This is particularly important in industries such as automotive manufacturing, where consistency and quality are critical.

In addition to improving efficiency, automatic systems also enhance safety by reducing the need for manual handling of hazardous materials. Operators can focus on monitoring the system and making adjustments as needed, rather than being directly involved in the coating process.

Examples of Specialized Equipment: Automatic coating systems can be customized to suit the specific needs of different industries. For example:

- Automotive Industry: In the automotive industry, automatic coating systems are used to apply durable, corrosion-resistant coatings to parts such as car bodies, wheels, and engine components. These systems often include high-precision robotic applicators that can handle complex shapes and contours.

- Appliance Manufacturing: In the appliance industry, automatic systems are used to coat large, flat surfaces such as refrigerator doors and washing machine panels. The systems are designed to provide a smooth, even finish that is both aesthetically pleasing and durable.

Automatic coating systems are a cornerstone of modern manufacturing, enabling companies to produce high-quality, consistent coatings at scale.

Aluminum Coating Machines

Aluminum coating machines are specialized equipment designed to handle the unique challenges of coating aluminum parts. Aluminum is widely used in industries such as construction, automotive, and electronics, where its lightweight and corrosion-resistant properties are highly valued. However, aluminum requires special consideration during the coating process to ensure proper adhesion and durability.

Specific Machinery for Aluminum Surfaces: Aluminum coating machines are designed to address the specific needs of aluminum, which can be more difficult to coat than other metals due to its non-ferrous nature. These machines include:

- Pre-Treatment Systems: Aluminum surfaces must be properly pre-treated before coating to remove oxidation and improve adhesion. Aluminum coating machines often include integrated pre-treatment systems that apply chemical treatments such as chromate or non-chromate conversion coatings.

- Powder Application Equipment: The powder application process for aluminum requires precise control to ensure even coverage and proper adhesion. Specialized spray guns or applicators may be used to achieve this, often with settings specifically calibrated for aluminum surfaces.

- Low-Temperature Curing Ovens: Aluminum is sensitive to high temperatures, which can cause warping or other damage. Aluminum coating machines typically include low-temperature curing ovens that cure the powder coating without compromising the integrity of the aluminum.

Adjustments Required for Different Aluminum Profiles: Aluminum parts come in a wide variety of shapes and sizes, from large, flat panels to intricate extrusions. Coating machines must be adaptable to these different profiles, ensuring that each part receives a consistent and high-quality finish.

- Flat Panels: For large, flat aluminum panels, coating machines are designed to apply powder evenly across the surface, ensuring a smooth finish without runs or sags. The curing process is carefully controlled to prevent warping.

- Extrusions and Complex Shapes: Aluminum extrusions and other complex shapes require specialized applicators that can reach into tight corners and around curves. The coating machines may use robotic arms or multi-axis spray guns to achieve full coverage.

Aluminum coating machines are essential for industries where high-quality finishes on aluminum parts are required, such as in construction, automotive, and consumer electronics.

Innovations in Specialized Coating Equipment

The field of powder coating is constantly evolving, with manufacturers developing new technologies and equipment to improve efficiency, quality, and sustainability. Innovations in specialized coating equipment are driving the industry forward, offering new solutions to old challenges.

Automatic Coating Systems with AI Integration: One of the most exciting developments in powder coating technology is the integration of artificial intelligence (AI) into automatic coating systems. AI allows these systems to learn and adapt to different coating scenarios, improving the consistency and quality of the final product.

- Adaptive Coating Processes: AI-powered systems can adjust the coating process in real-time based on feedback from sensors and cameras. For example, if the system detects an area with insufficient coverage, it can automatically adjust the spray pattern or powder flow to correct the issue.

- Predictive Maintenance: AI can also be used to monitor the condition of the coating equipment, predicting when maintenance is needed and preventing costly downtime. This leads to higher efficiency and reduced operating costs.

Sustainability Innovations: Environmental sustainability is a growing concern in the powder coating industry, and manufacturers are responding with new technologies designed to reduce waste and energy consumption.

- Powder Recycling Systems: Modern coating systems are equipped with advanced powder recycling systems that capture and reuse overspray, reducing waste and lowering material costs.

- Energy-Efficient Curing Ovens: New designs in curing ovens focus on reducing energy consumption without compromising the quality of the finish. These ovens use advanced insulation materials, energy-efficient burners, and precise temperature controls to minimize energy use.

These innovations are helping the powder coating industry become more sustainable while also improving the quality and efficiency of the coating process.

Environmental and Safety Considerations

Environmental Impact of Powder Coating

Powder coating is recognized as an environmentally friendly alternative to traditional liquid painting methods. It offers several environmental benefits that make it an attractive option for manufacturers looking to reduce their ecological footprint.

Benefits of Powder Coating Over Traditional Painting: Traditional liquid paints often contain solvents that release volatile organic compounds (VOCs) into the atmosphere during application and curing. VOCs contribute to air pollution and can have harmful effects on both the environment and human health. In contrast, powder coatings are solvent-free, which means they emit little to no VOCs. This significantly reduces the environmental impact of the coating process.

- Reduced Emissions: Because powder coatings do not contain solvents, they produce minimal emissions during application. This makes powder coating a much cleaner process, contributing to improved air quality in and around manufacturing facilities.

- Waste Minimization: Powder coating also generates less waste compared to traditional liquid painting. Oversprayed powder can be collected, filtered, and reused, resulting in higher material efficiency and reduced disposal costs. This closed-loop system minimizes the amount of waste sent to landfills.

- Energy Efficiency: The curing process for powder coatings is typically faster and requires less energy than drying liquid paints. Advances in curing technology, such as the use of infrared or UV curing, further reduce energy consumption, making the process even more sustainable.

These environmental benefits make powder coating an ideal choice for industries aiming to meet strict environmental regulations and reduce their carbon footprint.

Waste Management and Recycling in Powder Coating: One of the key advantages of powder coating is the ability to recycle oversprayed powder. In a typical powder coating booth, any powder that does not adhere to the workpiece is collected by a filtration system, such as a bag filter for powder coating. The collected powder is then returned to the application system for reuse.

- Powder Reclamation Systems: Modern powder coating systems are equipped with advanced powder reclamation systems that maximize the recovery of overspray. These systems can achieve reclamation rates of up to 98%, greatly reducing material waste and costs.

- Proper Disposal: Despite the high reclamation rates, there is still some waste generated in powder coating, such as used filters or residual powder that cannot be recycled. It is important for manufacturers to follow proper disposal procedures to ensure that any waste is handled in an environmentally responsible manner.

By incorporating efficient waste management and recycling practices, powder coating operations can minimize their environmental impact and contribute to more sustainable manufacturing practices.

Safety Protocols in Powder Coating Plants

While powder coating is generally safer than many traditional painting methods, it still involves handling potentially hazardous materials. To ensure the safety of workers and maintain compliance with industry regulations, it is essential to implement strict safety protocols in powder coating plants.

Handling Powder and Chemicals: Powder coating materials, while safer than liquid paints, can still pose health risks if not handled properly. Inhalation of powder particles can cause respiratory issues, and some powders may contain chemicals that can cause skin irritation or other health problems.

- Personal Protective Equipment (PPE): Workers in powder coating plants should always wear appropriate PPE, including respirators, gloves, and protective clothing. Respirators are particularly important when applying powder, as they protect against inhalation of fine particles.

- Ventilation Systems: Proper ventilation is crucial in powder coating booths to prevent the accumulation of powder particles in the air. Ventilation systems should be equipped with filters that capture overspray and keep the air clean. Regular maintenance of these systems is necessary to ensure they operate effectively.

- Safe Handling of Chemicals: In addition to the powder itself, the chemicals used in pretreatment processes, such as phosphate coatings, can be hazardous. Workers must be trained in the safe handling of these chemicals, including proper storage, mixing, and disposal procedures.

Safety Equipment and Best Practices: Ensuring the safety of workers in a powder coating plant involves more than just PPE. The facility should be equipped with safety equipment and follow best practices to prevent accidents and injuries.

- Fire Safety: Powder coating materials are combustible, and the fine powder particles can create an explosive atmosphere if not properly managed. Fire safety measures, such as explosion-proof equipment, regular cleaning to prevent powder accumulation, and proper grounding of equipment, are essential.

- Emergency Procedures: All workers should be trained in emergency procedures, including how to respond to fires, chemical spills, and other potential hazards. Emergency shut-off switches, fire extinguishers, and first-aid kits should be easily accessible throughout the facility.

- Regular Safety Audits: Conducting regular safety audits is important to identify potential hazards and ensure that safety protocols are being followed. Audits should include inspections of equipment, review of safety procedures, and verification that all workers are properly trained.

By prioritizing safety in powder coating plants, manufacturers can protect their workers, reduce the risk of accidents, and maintain a safe working environment.

Regulatory Compliance and Standards

Compliance with industry regulations and standards is critical for any powder coating operation. These regulations ensure that the processes used are safe for workers, environmentally responsible, and produce high-quality results.

Industry Standards and Certifications: Several organizations provide standards and certifications for powder coating processes. These standards cover everything from the quality of the coating to environmental and safety practices.

- ISO Standards: The International Organization for Standardization (ISO) offers a range of standards related to powder coating, including ISO 9001 for quality management and ISO 14001 for environmental management. Adhering to these standards demonstrates a commitment to quality and sustainability.

- OSHA Regulations: In the United States, the Occupational Safety and Health Administration (OSHA) sets regulations for workplace safety, including those related to powder coating. Compliance with OSHA regulations is mandatory and includes requirements for ventilation, PPE, chemical handling, and emergency procedures.

Staying Updated with Regulations: Regulations and standards can change, so it is important for powder coating plants to stay updated with the latest requirements. This may involve regular training for staff, updates to equipment and procedures, and ongoing communication with regulatory bodies.

Maintaining compliance with industry regulations and standards not only ensures the safety of workers and the environment but also enhances the reputation of the powder coating operation, making it more attractive to clients and partners.

Future Trends in Powder Coating Machinery and Equipment

Technological Advancements

The powder coating industry has always been driven by technological innovation, with new advancements continually improving the efficiency, quality, and versatility of the coating process. As we look to the future, several key technological trends are set to shape the industry.

Innovations in Powder Spray Machines: Powder spray machines are at the heart of the coating process, and ongoing developments are focused on improving their precision, efficiency, and ease of use.

- High-Precision Spray Guns: Advances in spray gun technology are enabling more precise control over powder application, allowing for thinner, more uniform coatings. These new spray guns can adjust the powder flow and spray pattern in real-time, ensuring consistent coverage even on complex surfaces.

- Smart Spray Systems: The integration of sensors and smart technologies into spray machines is another key trend. These systems can monitor variables such as powder particle size, spray velocity, and ambient conditions, adjusting settings automatically to maintain optimal coating quality. Smart spray systems reduce waste and improve the efficiency of the coating process, leading to cost savings and better overall results.

Development of More Efficient Powder Curing Equipment: Curing is a critical stage in the powder coating process, and advancements in curing technology are focused on reducing energy consumption and increasing the speed of the process.

- Infrared and UV Curing: Traditional convection ovens are being complemented or even replaced by infrared (IR) and ultraviolet (UV) curing systems. These systems offer faster curing times and lower energy use, as they directly target the coated surface rather than heating the entire part. IR and UV curing are particularly beneficial for parts that are sensitive to high temperatures, such as plastics or thin metals.

- Energy-Efficient Ovens: Innovations in oven design are leading to more energy-efficient curing processes. New ovens are being built with advanced insulation materials and more efficient burners, which reduce heat loss and lower overall energy consumption. Additionally, these ovens can be equipped with real-time monitoring systems that optimize the curing cycle based on the specific requirements of each batch, further improving efficiency.

These technological advancements in spray machines and curing equipment are making powder coating more efficient, sustainable, and adaptable to a wider range of applications.

Automation and AI in Powder Coating

Automation has been a driving force in the powder coating industry for years, but the integration of artificial intelligence (AI) is pushing the boundaries of what automated systems can achieve. AI is revolutionizing the powder coating process by enabling smarter, more adaptive systems that can optimize operations in real-time.

Emerging Trends in Automated Paint Coating: Automation in powder coating has traditionally focused on increasing throughput and consistency, but new developments are expanding its capabilities.

- Robotic Applicators with AI: The latest robotic applicators are now being equipped with AI that allows them to learn from previous operations and adapt to new challenges. For instance, AI-powered robots can analyze the geometry of a part and automatically adjust their movements to ensure complete coverage, even in hard-to-reach areas. This level of adaptability was previously only possible with skilled human operators.

- Automated Quality Control: AI is also being integrated into quality control processes, where it can quickly and accurately identify defects such as uneven coatings, pinholes, or contaminants. Automated systems equipped with machine vision can inspect parts as they are coated, flagging any issues in real-time and allowing for immediate adjustments to the process. This reduces the need for post-coating inspections and rework, leading to higher overall efficiency.

The Role of AI in Improving Efficiency and Reducing Waste: AI is particularly valuable in its ability to optimize the powder coating process, reducing waste and improving resource efficiency.

- Predictive Maintenance: AI systems can monitor the performance of powder coating equipment and predict when maintenance is needed. This prevents unexpected downtime and extends the life of the machinery. Predictive maintenance systems analyze data from sensors and other sources to identify patterns that indicate potential issues, allowing for proactive maintenance rather than reactive repairs.

- Adaptive Process Control: AI can adjust the coating process in real-time based on a variety of factors, such as changes in temperature, humidity, or powder characteristics. This adaptability ensures that the coating process remains consistent even in changing conditions, reducing the likelihood of defects and improving overall quality. By optimizing powder usage, AI-driven systems also reduce material waste, contributing to more sustainable operations.

As AI continues to evolve, its impact on the powder coating industry is expected to grow, leading to smarter, more efficient, and highly adaptable systems.

Sustainability in Powder Coating

Sustainability is becoming an increasingly important consideration in the powder coating industry, driven by both regulatory requirements and consumer demand for environmentally responsible products. The future of powder coating will be shaped by innovations that reduce the environmental impact of the process while maintaining or improving coating performance.

Sustainable Practices in Powder Coating: Several sustainable practices are emerging in the powder coating industry, aimed at reducing waste, energy consumption, and the use of hazardous materials.

- Low-Temperature Curing Powders: One of the most significant developments in sustainable powder coating is the creation of low-temperature curing powders. These powders cure at lower temperatures, reducing the energy required for the process. Lower curing temperatures also expand the range of materials that can be coated, including heat-sensitive substrates like plastics or composites. This innovation not only cuts down on energy use but also opens up new applications for powder coating.

- Eco-Friendly Powder Formulations: Manufacturers are developing powder coatings with reduced environmental impact, including powders that are free of hazardous materials like TGIC (triglycidyl isocyanurate) or heavy metals. These eco-friendly formulations are designed to meet stringent environmental regulations while still delivering the same high-performance characteristics as traditional powders.

- Recycling and Reuse: The ability to recycle and reuse oversprayed powder is a significant advantage of powder coating. As powder reclamation technology improves, more facilities are able to capture and reuse nearly all of the powder that doesn’t adhere to the part during the initial application. This not only reduces waste but also lowers material costs, making powder coating more economical and sustainable.

Future of Eco-Friendly Coating Systems: The drive toward sustainability is likely to result in even more eco-friendly coating systems in the future.

- Water-Based Pretreatment Systems: Traditional chemical pretreatment processes often use hazardous substances that can be harmful to the environment. In response, the industry is moving toward water-based pretreatment systems that are less toxic and easier to dispose of. These systems use environmentally friendly chemicals and generate less hazardous waste, making them a more sustainable option for surface preparation.

- Solar-Powered Coating Facilities: As the cost of renewable energy continues to fall, more powder coating facilities are likely to adopt solar power or other renewable energy sources to reduce their carbon footprint. Solar panels can be installed on the roofs of coating plants to generate electricity for the coating process, further enhancing the sustainability of the operation.

Sustainability is not just a trend but a fundamental shift in how the powder coating industry operates. Companies that embrace sustainable practices and technologies will be better positioned to meet future regulatory requirements and consumer expectations.

Not only do we manufacture our powder coating equipment, we also ship them worldwide to your facility with care

We’re not just the manufacturers of your powder coating equipment, we’re also your worldwide delivery partners.

At EMS Powder Coating Equipment, we understand that getting your powder coating equipment to you quickly and safely is just as important as manufacturing it to the highest standards. That’s why we offer worldwide delivery services to all of our customers.

We work with a network of experienced and reliable shipping partners to ensure that your equipment arrives on time and in perfect condition. We also offer a variety of shipping options to fit your budget and needs.

Whether you need your equipment shipped to a local address or to an international destination, we can help. We’ll work with you to choose the best shipping option for your needs and to keep you updated on the status of your shipment every step of the way.

So when you choose EMS for your powder coating equipment, you’re not just getting the best products on the market, you’re also getting the best possible delivery experience.

Contact us today to learn more about our worldwide delivery services.