Automatic Painting and Powder Paint Coating Line for Small Parts: A fast coating machine for small metal items is a specialized industrial system engineered to apply protective or decorative coatings efficiently onto miniature or compact metallic components. These machines are designed with precision, speed, and consistency in mind, catering especially to manufacturers who handle high volumes of small parts such as screws, bolts, washers, pins, clips, hinges, fittings, and electronic hardware. Industries that benefit most from such machinery include automotive, aerospace, electronics, consumer goods, and hardware manufacturing.

One of the most critical aspects of coating small metal items is ensuring uniform coverage across all surfaces — including hard-to-reach cavities or complex geometries — without over-coating, clumping, or waste. Fast coating machines achieve this through the use of automated spraying systems, fluidized beds, electrostatic powder guns, or dip-spin mechanisms. Each method can be adapted to suit different types of coatings, including powder coatings, liquid paints, epoxy resins, zinc-rich primers, or specialized corrosion-resistant finishes.

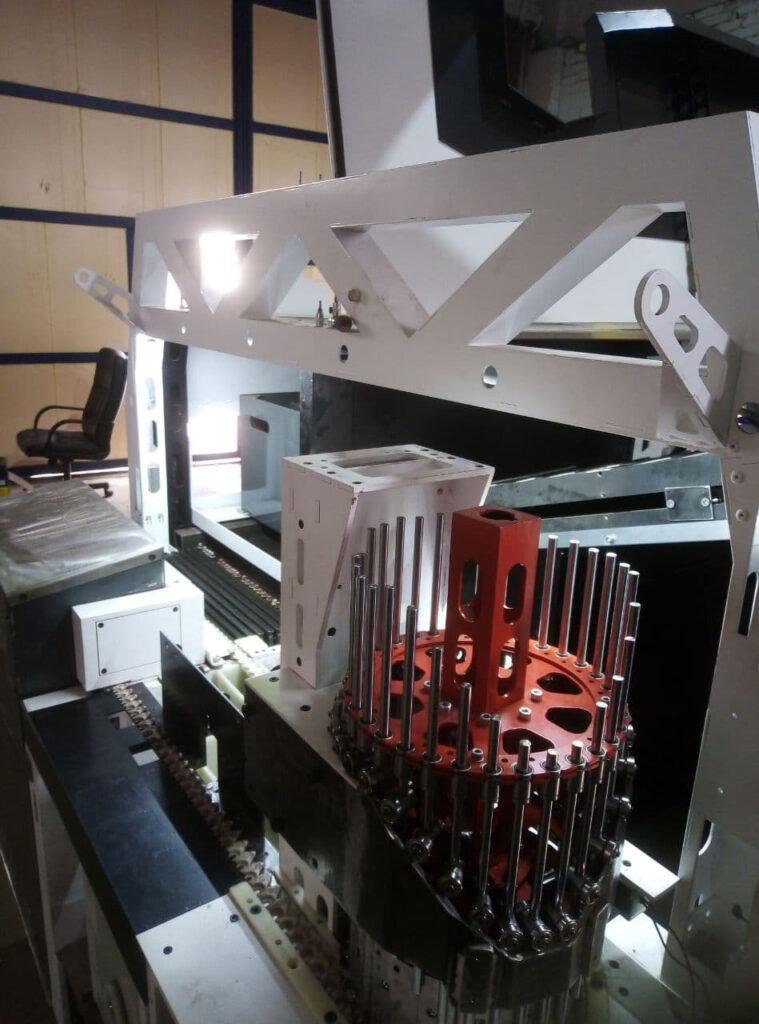

Speed and throughput are defining characteristics of these machines. Unlike manual or semi-automatic systems, fast coating machines are designed for continuous or batch operation, often incorporating rotary tables, conveyor belts, vibrating feed hoppers, or rotating baskets that can process thousands of items per hour. Their automation systems are typically managed by PLCs (programmable logic controllers), enabling precise timing, material flow, spray duration, and curing cycles.

The coating quality is maintained by integrating real-time monitoring systems, including sensors that check temperature, humidity, coating thickness, and curing profiles. This ensures not only rapid processing but also repeatable quality, which is essential for parts that must meet stringent technical standards — especially in critical sectors like aerospace or electronics.

Some fast coating machines also feature integrated pre-treatment units, such as ultrasonic cleaners, degreasers, or phosphate coating baths, allowing a complete surface preparation and coating line within a compact footprint. After coating, automated drying or curing ovens — often using infrared or convection heating — harden the finish quickly, reducing handling time and minimizing the risk of contamination or damage.

From a cost-efficiency standpoint, fast coating machines reduce material waste through closed-loop systems and precision application controls. Powder recovery systems, filtration units, and spray pattern optimization help conserve expensive coating materials. Moreover, the minimized need for human labor reduces operational costs and safety risks.

The footprint of these machines can vary. Compact tabletop units are available for laboratory-scale or prototyping work, while large industrial systems can handle multi-ton loads per hour in a fully enclosed and filtered environment. Modular design allows easy integration into existing production lines, and flexibility in design enables manufacturers to switch between different item sizes or coating materials with minimal downtime.

In summary, fast coating machines for small metal items represent a cornerstone of modern industrial finishing technology. They provide rapid, reliable, and high-quality coating performance while keeping operational costs low and ensuring compliance with environmental and safety regulations. For any manufacturer working with high volumes of small metal parts, investing in such a system can lead to significant improvements in product durability, aesthetic appeal, and production efficiency.

Fast coating machines for small metal items are essential in modern manufacturing environments where efficiency, consistency, and speed are critical. These machines are engineered to handle vast quantities of small metallic components such as screws, bolts, fasteners, clips, fittings, and other intricate pieces that require a protective or decorative coating. Their core function is to deliver a uniform finish across all surfaces of each item, even when those items have complex geometries or fine details that are traditionally difficult to coat evenly. By automating the coating process, these machines eliminate the inconsistencies often found in manual applications and greatly reduce the time needed for processing large batches. High-speed coating equipment typically utilizes rotary drums, vibratory bowls, or spin baskets that move items continuously or in timed cycles through the coating area, ensuring complete and even coverage. The application methods may vary from electrostatic powder spraying to dip-spin systems or even fluidized beds, depending on the coating type and end-use requirement.

These systems are often complemented by automated pre-treatment and drying units, including cleaning stages that remove oils, rust, and contaminants, and curing ovens that harden the applied material in a controlled thermal environment. Modern machines are equipped with smart sensors and digital controllers to monitor and adjust process variables such as temperature, coating thickness, and timing, ensuring each item meets precise specifications without the need for rework. Not only do they enhance the quality and longevity of the finished product, but they also increase production throughput while minimizing material waste through accurate dosing and closed-loop systems that recover excess coating material. Their compact and modular designs allow integration into existing production lines, and many offer quick-change features that enable manufacturers to shift from one type of product to another with minimal downtime. Whether in high-volume industries like automotive, aerospace, consumer electronics, or home hardware production, fast coating machines serve as a vital solution to the challenges of coating small-scale metal items at industrial speed and scale. They help reduce labor costs, improve workplace safety, and support environmental compliance by reducing overspray, emissions, and hazardous waste. As demand for precision-coated micro-components grows, these machines continue to evolve, offering higher automation levels, better coating accuracy, and shorter cycle times — making them indispensable tools in any modern factory that handles small metal items requiring consistent, durable surface finishes.

The evolution of fast coating machines for small metal items continues to be driven by technological advancements and increasing demands for precision and sustainability. Manufacturers today seek not only speed and volume but also high levels of customization and control over the coating process. To meet these requirements, many machines are now equipped with advanced PLC or HMI interfaces, allowing operators to program exact coating recipes for different products. These settings can include spray angle, material flow rate, part rotation speed, and dwell time in pre-treatment or curing zones. This high degree of control ensures that even the smallest variations in item shape or material composition can be accommodated without compromising quality or wasting resources.

Another key advantage of these systems is their flexibility. With interchangeable drums, baskets, or trays, and modular attachments, the same machine can be adapted to coat a wide variety of items — from tiny fasteners to small stamped or turned components. The changeover between different items or coatings is made quick and efficient, reducing downtime and increasing productivity. Many systems also include automated feeding and unloading systems, such as vibratory feeders, pick-and-place robots, or chute conveyors, which minimize the need for manual handling and reduce the risk of contamination or damage during transfer.

In industries with strict quality requirements, such as electronics or aerospace, fast coating machines are often integrated with inspection stations that use machine vision or laser measurement tools to verify the quality and consistency of the coating in real-time. Defective items can be automatically rejected or reprocessed without halting the entire production line. This level of quality assurance is essential when coating functions not only for appearance but also for electrical insulation, corrosion resistance, or mechanical protection.

From an environmental perspective, many modern coating machines are designed with sustainability in mind. Low-VOC or solvent-free coating systems are increasingly being used, along with highly efficient air filtration units and powder recovery systems. These features help manufacturers meet environmental regulations while also reducing material costs and energy consumption. Heat recovery systems may be employed in curing ovens to recycle waste heat, further lowering the machine’s overall energy footprint.

Maintenance and reliability are also central concerns for manufacturers operating 24/7 production lines. Fast coating machines are built with robust components and often feature predictive maintenance systems that alert operators to wear and tear before a breakdown occurs. Easy access panels, tool-free disassembly, and self-cleaning features make routine maintenance quicker and more manageable, ensuring minimal disruption to production.

In a world where product variety is increasing, delivery times are shrinking, and quality standards are rising, the role of the fast coating machine for small metal items is more critical than ever. These machines empower manufacturers to meet diverse customer demands while maintaining high throughput, consistent finish quality, and cost efficiency. They are not just pieces of equipment but essential parts of a highly synchronized production ecosystem, contributing directly to a company’s competitiveness, sustainability, and ability to innovate. As coating technologies continue to evolve, incorporating features like AI-assisted process optimization or hybrid coating capabilities, the machines will only become smarter, faster, and more indispensable in precision manufacturing environments.

Powder Coating System for Tiny Objects

A powder coating system for tiny objects is a highly specialized finishing solution designed to apply durable, uniform powder coatings onto miniature metal components such as screws, nuts, washers, pins, springs, connectors, clips, and other small hardware or precision parts. Unlike conventional spray booths or manual powder application methods, systems for tiny objects are engineered to process thousands of small items quickly and consistently, minimizing material waste and maximizing surface coverage even in complex or hard-to-reach geometries.

At the core of these systems is the electrostatic powder coating process, where dry powder particles are electrically charged and sprayed onto grounded metal objects. The powder adheres through electrostatic attraction and is then melted and cured in a high-temperature oven to form a tough, smooth, and even finish. For small objects, traditional spraying methods are often inefficient due to the items’ size, shape, and tendency to move or scatter during coating. To overcome this, dedicated systems employ methods like rotary drums, vibrating trays, tumblers, dip-spin coaters, or fluidized beds. These ensure constant motion and exposure of all surfaces while preventing clumping or uneven layering.

The dip-spin coating technique is particularly popular for fasteners and small bulk items. In this process, the parts are submerged in a powder slurry or powder cloud, then spun at high speed to remove excess coating. This ensures uniform distribution without pooling or bridging. Some systems use miniature spray chambers with rotary baskets, where the powder is sprayed into a rotating container filled with parts, allowing controlled deposition across all surfaces.

To ensure adhesion and finish quality, powder coating systems for tiny objects often include pre-treatment stages such as ultrasonic cleaning, degreasing, phosphating, or sandblasting to remove oil, dust, and rust. Once coated, the parts are typically conveyed or tumbled through a curing oven where the powder fuses into a smooth, solid film. Curing ovens for tiny objects must maintain very precise temperature control to avoid undercuring or overheating, especially when processing sensitive or thin-walled components.

Automation plays a key role in improving efficiency and consistency. Modern systems are equipped with programmable logic controllers (PLCs) that manage timing, rotation speed, spray duration, and oven temperatures. Sensors may monitor coating thickness, part temperature, or humidity, while integrated recovery units capture and recycle overspray powder, significantly reducing material loss.

One of the greatest advantages of powder coating for tiny objects is the ability to produce high-performance finishes—resistant to corrosion, abrasion, UV degradation, and chemicals—without solvents or hazardous emissions. Powder coatings also allow a wide variety of colors, gloss levels, and textures to be applied with excellent repeatability and minimal waste. This makes them ideal for sectors like electronics, medical devices, automotive parts, tools, and even decorative consumer goods where both appearance and durability are critical.

Scalability is another strength. From benchtop powder coating units for research labs or prototyping, to fully automated high-throughput systems for mass production, the technology can be adapted to meet a wide range of production volumes and part types. The choice of system depends on factors like part geometry, required finish quality, production rate, and available floor space.

In summary, powder coating systems for tiny objects are purpose-built to handle the challenges of finishing small, detailed, and numerous components efficiently and reliably. They combine precision handling, advanced application techniques, and tightly controlled curing processes to deliver high-quality, cost-effective finishes that meet the rigorous demands of modern industry.

Powder coating systems for tiny objects have become indispensable in industries where small metal parts require robust and aesthetically pleasing finishes. These systems are designed to overcome the unique challenges posed by the size and shape of miniature components. Because tiny parts can easily clump together or shift during coating, specialized equipment ensures consistent movement and exposure to the powder, preventing uneven coverage or defects such as bare spots or thick build-ups. Technologies such as vibrating feeders, rotating drums, or tumbling baskets are often integrated to maintain constant agitation and separate parts for uniform coating.

The application process is carefully controlled to achieve optimal electrostatic charge on the powder particles and ensure they firmly adhere to the grounded metal surfaces. Precise control over parameters like spray pressure, powder flow rate, and environmental conditions is critical because even minor variations can affect coating thickness and finish quality. The systems are often housed in enclosed chambers equipped with extraction and filtration units to contain powder overspray and maintain a clean work environment. This also helps protect operators from inhaling fine particles and ensures compliance with workplace safety regulations.

Another important aspect is the recovery and reuse of unused powder. Because powder coating materials can be costly, efficient recovery systems with filters and cyclones capture excess powder that falls off parts during application. This powder is then cleaned and recycled back into the process, significantly reducing material waste and operating costs. The level of automation in these systems helps minimize manual intervention, reducing labor costs and improving repeatability. Operators can program coating recipes that tailor the process to specific parts or batches, allowing for quick changeovers and high flexibility in production.

After coating, tiny parts are typically cured in specially designed ovens that ensure uniform heat distribution and precise temperature control. The curing process causes the powder to melt, flow, and chemically crosslink, resulting in a tough, seamless coating that adheres strongly to the substrate. For tiny objects, oven design often incorporates conveyors or rotating drums to prevent parts from sticking together or accumulating in one area, which could cause uneven curing or damage. The curing cycle is optimized to balance throughput with coating performance, avoiding overheating that might distort delicate parts or undercuring that could compromise durability.

These powder coating systems not only provide exceptional corrosion resistance and mechanical protection but also enable manufacturers to meet stringent industry standards related to environmental impact. Powder coatings are solvent-free and emit virtually no volatile organic compounds (VOCs), making them an eco-friendly alternative to traditional liquid paints. Their durability also reduces the need for rework or replacement, contributing to sustainability through longer-lasting products.

In addition to standard finishes, powder coating systems for tiny objects can handle specialty powders with properties such as anti-static, conductive, flame retardant, or textured finishes, expanding their applicability across different sectors. This versatility is valuable for manufacturers who produce parts for electronics, automotive components, medical instruments, and consumer goods, where performance and appearance are equally important.

Ultimately, investing in a powder coating system tailored for tiny metal parts allows manufacturers to streamline their finishing operations, improve product quality, and reduce operational costs. As automation and coating technology continue to advance, these systems will offer even greater precision, higher throughput, and enhanced process control — enabling companies to keep pace with evolving market demands and maintain a competitive edge in industries reliant on small, high-quality coated components.

As powder coating systems for tiny objects advance, integration with smart manufacturing technologies is becoming increasingly common. These systems now often feature connectivity to industrial IoT platforms, enabling real-time monitoring, data collection, and process analytics. By tracking variables such as coating thickness, powder consumption, curing temperatures, and equipment status, manufacturers can optimize operations, predict maintenance needs, and quickly address quality issues before they escalate. This data-driven approach enhances yield, reduces downtime, and supports continuous improvement initiatives.

Customization is another growing trend. Manufacturers can fine-tune coating parameters to meet very specific requirements, whether it’s applying ultra-thin layers for electrical insulation or thicker coatings for enhanced corrosion resistance. This flexibility is critical as industries demand ever more specialized finishes for miniaturized components in sectors like aerospace, electronics, and medical devices, where even minor deviations can impact performance or safety.

Moreover, the development of new powder materials expands what can be achieved with these systems. Innovations such as hybrid powders combining different resin chemistries, powders with embedded nanoparticles for improved wear resistance, or powders formulated for rapid curing contribute to better functionality and faster production cycles. This continual evolution of coating materials works hand-in-hand with machine capabilities to deliver state-of-the-art finishes tailored for tiny parts.

Ergonomics and safety remain priorities in modern powder coating setups. Closed-loop systems minimize operator exposure to powder dust, while automated loading and unloading reduce repetitive strain injuries. Machine designs often include easy-to-clean surfaces and accessible components, making maintenance simpler and reducing downtime.

From a business perspective, powder coating systems for tiny objects provide manufacturers with a competitive edge by enabling fast turnaround times, consistent quality, and cost-effective use of materials. They support scaling production from prototype batches to full-scale manufacturing with minimal process changes, thus accelerating time-to-market for new products.

In conclusion, powder coating systems designed for tiny metal parts represent a fusion of precision engineering, material science, and automation technology. They address the unique challenges posed by small-scale components, delivering durable, high-quality finishes that meet demanding industry standards while promoting operational efficiency and sustainability. As these systems continue to integrate smart features and novel materials, their role in precision manufacturing will only grow more vital, helping companies innovate and excel in increasingly competitive global markets.

Fine Powder Coating Machine for Small Products

A fine powder coating machine for small products is a highly specialized industrial device designed to apply ultra-fine, uniform powder coatings onto small-scale metal or plastic components with precision and efficiency. These machines cater especially to manufacturers producing tiny parts such as fasteners, small fittings, electronic connectors, jewelry components, medical instruments, and other miniature items that require a smooth, durable, and aesthetically appealing finish. Unlike standard powder coating equipment, fine powder coating machines focus on delivering exceptionally controlled coating thicknesses and superior surface quality, which is critical when dealing with delicate or intricate small parts.

The technology behind these machines involves electrostatically charging fine powder particles so they adhere evenly to grounded parts. Due to the small size and often complex shapes of the products, these machines incorporate specialized application systems such as rotary baskets, tumblers, vibratory feeders, or fluidized bed systems. These mechanisms keep the small products in constant motion during coating, ensuring all surfaces receive equal powder coverage while preventing powder clumping or bridging between parts. The fine particle size of the powder itself allows for a smooth finish that enhances both the visual appeal and functional properties such as corrosion resistance, electrical insulation, and wear protection.

Precision control is a hallmark of fine powder coating machines for small products. Modern units use programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to regulate critical parameters like powder flow rate, spray gun voltage, part rotation speed, and coating time. This ensures repeatability and the ability to quickly switch between different product types or coating materials without compromising quality. Many machines also include advanced filtration and powder recovery systems to minimize waste, capturing overspray and recycling unused powder, which helps reduce operating costs and environmental impact.

Pre-treatment and curing are equally important components of the coating process for fine powder coating machines. Often integrated or designed to work seamlessly with the coating equipment, pre-treatment units clean and prepare the surfaces to maximize adhesion and coating performance. Following powder application, curing ovens precisely heat the coated parts to fuse the powder into a continuous, hard finish. For small and delicate parts, curing cycles are optimized to prevent overheating or distortion while achieving complete polymerization of the coating.

Fine powder coating machines are designed to be compact and adaptable to various production scales, from small-batch prototyping to high-volume manufacturing. Their modular construction allows integration into automated production lines or standalone operation, depending on the manufacturer’s needs. Safety features such as enclosed spray booths, proper ventilation, and operator safeguards ensure compliance with industry regulations and create a safer working environment.

In industries where small product quality and finish are paramount—such as aerospace, medical devices, electronics, and precision engineering—fine powder coating machines provide a reliable, efficient, and environmentally friendly solution. By combining advanced powder technology, precision equipment design, and automation, these machines enable manufacturers to achieve superior coating results on small products while optimizing productivity and minimizing costs.

Fine powder coating machines for small products continue to evolve with the integration of new technologies that enhance precision, efficiency, and environmental sustainability. One significant advancement is the incorporation of real-time monitoring and feedback systems, which allow operators to track coating parameters such as thickness, powder consumption, and electrostatic charge during the coating process. This ensures that each batch meets stringent quality standards and reduces the likelihood of defects, rework, or waste. Automated adjustments can be made on-the-fly, optimizing the coating process without interrupting production.

The machines are also designed to handle a wide variety of powder types, including specialized powders that offer properties like anti-microbial resistance, electrical conductivity, or improved chemical resistance. This versatility allows manufacturers to tailor the coating process to specific application requirements, whether it’s protecting delicate electronic components or enhancing the durability of small mechanical parts. The fine particle powders used in these machines contribute to smoother finishes and better coverage in tight spaces, which is particularly important for products with intricate designs or tight tolerances.

Automation plays a critical role in fine powder coating systems, especially for small products that are difficult to handle manually. Automated feeding and unloading systems reduce human intervention, minimizing handling damage and contamination risks. Robotic arms, vibratory feeders, and conveyor systems can be synchronized with the coating operation to create continuous, high-throughput production lines. This level of automation also improves workplace safety by limiting operator exposure to powder dust and moving parts.

Maintenance and ease of use are key considerations in the design of these machines. Components such as spray guns, filters, and powder recovery units are made accessible for quick cleaning and replacement. Many machines include self-cleaning features that reduce downtime and help maintain consistent coating quality. Additionally, modular designs allow manufacturers to scale or customize their systems as production demands change, ensuring long-term flexibility and return on investment.

Energy efficiency is another important aspect. Modern fine powder coating machines often incorporate energy-saving features such as variable frequency drives (VFDs) on motors, efficient curing ovens with heat recovery systems, and optimized airflow management. These innovations help reduce operational costs and the environmental footprint of the coating process, which is increasingly important as manufacturers face stricter regulations and customer demands for sustainable production.

Ultimately, fine powder coating machines for small products provide manufacturers with a powerful tool to achieve high-quality finishes on delicate, intricate parts at scale. By combining advanced powder technology, precision application methods, and automation, these machines enhance productivity, reduce waste, and ensure consistent, durable coatings that meet or exceed industry standards. As the demand for smaller, more complex components grows across sectors like electronics, medical devices, aerospace, and consumer goods, fine powder coating systems will continue to play a crucial role in delivering finishes that protect and beautify these products while supporting efficient and sustainable manufacturing practices.

As the demand for even greater precision and efficiency grows, fine powder coating machines for small products are increasingly integrating cutting-edge technologies such as artificial intelligence (AI) and machine learning algorithms. These advancements enable the systems to analyze vast amounts of process data, identify patterns, and optimize coating parameters automatically. For example, AI can predict and correct deviations in powder flow, spray consistency, or curing temperature before they affect product quality. This predictive capability reduces downtime, lowers waste, and enhances overall throughput without the need for constant human oversight.

Additionally, innovations in powder formulation are expanding the capabilities of fine powder coating systems. Nano-sized powders and hybrid coatings offer enhanced properties such as superior adhesion, improved abrasion resistance, and multifunctional surfaces—like anti-fingerprint or self-cleaning effects—which are especially valuable for small, precision parts in electronics and medical devices. These new powders often require fine-tuned application and curing conditions, prompting further refinement in machine controls and sensor technology.

Customization remains a significant focus. Manufacturers can now specify coating parameters at a granular level, allowing for multilayer coatings or variable thicknesses on different parts of the same batch. This level of control opens doors to novel applications and finishes that were previously impractical or impossible with traditional powder coating methods. Fine powder coating machines often come with software platforms that facilitate recipe management, traceability, and integration with broader manufacturing execution systems (MES), enabling seamless production workflows and quality assurance.

Sustainability continues to drive innovation as well. Newer systems emphasize reducing energy consumption, minimizing powder waste through enhanced recovery systems, and using environmentally friendly powders free of heavy metals or hazardous substances. By aligning with green manufacturing principles, companies not only comply with stricter regulations but also meet growing consumer and industry expectations for responsible production.

In terms of design, ergonomic and user-friendly interfaces make these machines accessible even to operators without extensive technical training. Touchscreen controls, intuitive software, and guided maintenance alerts simplify operation and upkeep, increasing reliability and reducing operator errors. Safety features such as enclosed spray booths, automated powder containment, and dust extraction ensure compliance with health standards and protect workers from exposure.

Looking ahead, fine powder coating machines for small products are poised to become even more compact and modular, allowing easy integration into versatile production lines, including those for additive manufacturing or hybrid manufacturing processes. This adaptability will support the rapid prototyping and small-batch production demands typical of advanced manufacturing sectors.

In essence, these machines represent the convergence of material science, automation, and digital technology, delivering highly controlled, efficient, and sustainable finishing solutions tailored to the exacting needs of small product manufacturers. As industries continue to innovate and miniaturize their components, fine powder coating technology will be instrumental in providing the protective, functional, and aesthetic coatings that enable performance and longevity in the smallest of products.

Automatic Powder Coaters for Miniature Parts

Automatic powder coaters for miniature parts are advanced industrial systems designed to efficiently apply powder coatings to tiny components with high precision and consistency. These machines are engineered to handle the unique challenges posed by miniature parts such as screws, springs, electronic connectors, small fittings, and medical device components, which often have complex shapes and require uniform coating coverage without defects. Automation in these systems drastically reduces manual labor, improves throughput, and ensures repeatable quality across large production volumes.

The core technology behind automatic powder coaters involves electrostatic application, where powder particles are charged and sprayed onto grounded miniature parts. Because manual handling of small parts can lead to inconsistent coating, damage, or contamination, automatic systems use specialized fixtures, rotary baskets, tumblers, or vibratory feeders to keep parts moving and evenly exposed to the powder spray. These mechanisms prevent clumping and ensure complete surface coverage, including hard-to-reach areas.

Integrated conveyor systems and robotic arms automate the loading and unloading of parts, minimizing human intervention and increasing production speed. The coating parameters—such as spray duration, gun voltage, powder flow, and part rotation speed—are controlled via programmable logic controllers (PLCs) with user-friendly interfaces, allowing precise adjustment for different part geometries and coating materials. This level of automation also enables quick changeovers between product batches, enhancing manufacturing flexibility.

Pre-treatment stages, often included as part of the automated line, prepare the miniature parts by cleaning and activating their surfaces to improve powder adhesion. After coating, parts pass through curing ovens with controlled temperature profiles to melt and harden the powder into a durable, continuous film. For miniature parts, ovens are designed to maintain uniform heat distribution and prevent part deformation or sticking, which is critical for maintaining dimensional accuracy and functional performance.

Automatic powder coaters for miniature parts often incorporate powder recovery and filtration systems to capture and recycle overspray powder, reducing material waste and lowering operational costs. Environmental controls within the coating area help contain powder dust and maintain a clean workspace, contributing to operator safety and regulatory compliance.

These automated systems are highly valuable in industries such as electronics, aerospace, medical device manufacturing, automotive, and precision engineering, where high-quality finishes on small parts are essential for performance, longevity, and aesthetics. By combining automation, precise powder application, and integrated curing, automatic powder coaters provide a reliable, cost-effective solution to meet the demanding requirements of miniature part coating at scale.

Automatic powder coaters for miniature parts continue to evolve with a focus on enhancing efficiency, precision, and environmental sustainability. Their automation capabilities not only speed up the coating process but also reduce human errors and inconsistencies common in manual operations. By continuously moving parts through controlled coating chambers using rotating baskets, vibratory feeders, or tumbling mechanisms, these machines ensure uniform coverage even on complex geometries and tiny features. This movement prevents parts from sticking together or developing uneven coatings, which can compromise both appearance and functionality.

Advanced control systems play a critical role in optimizing the coating process. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) allow operators to tailor coating parameters such as powder flow rate, electrostatic voltage, spray time, and part agitation speed to the specific requirements of each miniature part type. This adaptability is essential for handling diverse product lines or rapidly changing production schedules, making automatic powder coaters highly flexible. Furthermore, these systems can be integrated with factory-wide production management software for real-time monitoring, quality control, and data analytics, enabling manufacturers to maintain consistent product quality and quickly respond to any deviations.

The integration of automated pre-treatment modules streamlines the surface preparation process, ensuring that miniature parts are free from oils, dirt, and oxidation before coating. This step is vital for achieving strong powder adhesion and long-lasting finishes. After coating, parts move through precision curing ovens designed to provide consistent heat without overheating or warping delicate components. These ovens often include conveyors or rotating drums to maintain part separation and uniform exposure to heat, guaranteeing that coatings fully cure and develop their intended protective and aesthetic properties.

Environmental and safety considerations are integral to automatic powder coating systems for miniature parts. Efficient powder recovery units capture unused powder for reuse, minimizing waste and reducing material costs. Enclosed coating booths with advanced filtration prevent powder from escaping into the work environment, protecting operators and complying with health regulations. Many modern systems also focus on energy efficiency, employing heat recovery, variable-speed motors, and optimized airflow to reduce power consumption and operational expenses.

Automatic powder coaters are particularly valuable in industries requiring high volumes of small, precisely coated components, such as electronics, medical devices, aerospace, and automotive manufacturing. These systems enable manufacturers to produce consistent, high-quality finishes that enhance corrosion resistance, electrical insulation, and aesthetic appeal while maintaining fast production cycles. By automating the entire coating process—from loading through curing—these machines reduce labor costs, increase throughput, and improve overall operational efficiency.

Looking forward, ongoing innovations are expected to further enhance the capabilities of automatic powder coaters for miniature parts. Developments in sensor technology, artificial intelligence, and machine learning will enable even smarter process controls and predictive maintenance, reducing downtime and improving product quality. Additionally, advancements in powder materials, such as nano-enhanced coatings and hybrid formulations, will expand the functional properties and finishing options available for miniature parts.

In summary, automatic powder coating machines for miniature parts represent a sophisticated fusion of automation, material science, and process engineering. They address the specific challenges of coating tiny, complex components with speed, precision, and repeatability. As manufacturing demands continue to grow in complexity and scale, these systems will remain essential tools for delivering durable, high-performance coatings that meet stringent industry standards while supporting efficient, sustainable production.

As the market for miniature components expands, driven by trends like miniaturization in electronics, medical devices, and aerospace, automatic powder coaters are increasingly designed with modularity and scalability in mind. Manufacturers can configure systems to accommodate varying batch sizes, from small prototype runs to high-volume mass production, without sacrificing coating quality or efficiency. Modular designs allow quick adaptation or expansion, enabling companies to respond rapidly to changing product requirements or market demands.

Moreover, these machines often incorporate advanced robotics for material handling, reducing the risk of damage to delicate parts during loading, coating, and unloading stages. Collaborative robots (cobots) may be employed to work safely alongside human operators, enhancing flexibility and throughput while maintaining high safety standards. This integration of robotics also facilitates seamless transitions between different product types, allowing manufacturers to maintain continuous production with minimal downtime.

In terms of sustainability, automatic powder coaters continue to push boundaries by adopting green manufacturing principles. Powder recovery systems are becoming more efficient, capturing nearly all overspray for reuse, which reduces waste significantly. Some systems utilize powders formulated without heavy metals or other hazardous substances, aligning with increasingly stringent environmental regulations and corporate responsibility goals. Energy-efficient curing ovens, featuring infrared or convection heating combined with heat recovery, reduce overall energy consumption and carbon footprint.

The software aspect of automatic powder coating systems is also advancing rapidly. Integration with Industry 4.0 and smart factory platforms enables real-time process monitoring, predictive analytics, and remote troubleshooting. This connectivity helps manufacturers optimize resource usage, maintain consistent quality, and plan maintenance proactively, thereby minimizing unplanned downtime and production losses.

Quality control is enhanced by in-line inspection technologies that use machine vision and laser measurement tools to detect coating defects, thickness variations, or surface irregularities immediately after coating or curing. This immediate feedback allows for corrective action before products proceed further down the production line or reach customers, ensuring only parts that meet exacting standards are shipped.

Ultimately, automatic powder coaters for miniature parts represent a convergence of cutting-edge automation, advanced materials, and digital technologies. They provide manufacturers with the tools needed to meet the ever-growing demand for tiny, high-quality components with durable, uniform finishes. By improving efficiency, reducing waste, and enabling precise control, these systems play a vital role in modern manufacturing, helping companies innovate, compete globally, and deliver superior products in sectors where performance and reliability are paramount.

Precision Coating Line for Tiny Components

A precision coating line for tiny components is a highly engineered production system designed to apply consistent, high-quality coatings to very small parts with exacting control over every stage of the process. These components—which may include micro fasteners, miniature electronic connectors, medical device parts, or fine mechanical elements—demand flawless finishes to ensure performance, durability, and reliability in their final applications. The precision coating line integrates advanced automation, surface preparation, coating application, curing, and quality inspection into a seamless workflow tailored to the unique challenges of handling and finishing tiny components.

At the heart of such a line is the ability to maintain precise control over coating thickness, uniformity, and adhesion despite the minute size and complex shapes of the parts. Specialized handling systems like vibratory feeders, rotary baskets, or tumblers keep parts moving continuously and separated during coating to prevent damage or uneven coverage. Automated spray or dip coating stations utilize finely tuned parameters to apply coatings uniformly, often using electrostatic powder, liquid paints, or thin film deposition methods depending on the required finish and functional properties.

Pre-treatment modules are integrated to clean, activate, or chemically modify surfaces prior to coating, removing oils, contaminants, or oxides that could hinder adhesion. These stages might include ultrasonic cleaning, chemical baths, or plasma treatments carefully optimized for delicate parts to avoid damage. Following coating application, curing ovens with uniform temperature distribution solidify the coatings, often employing infrared, convection, or UV curing technologies based on the coating material and substrate sensitivity.

Precision coating lines incorporate real-time monitoring and process control through programmable logic controllers (PLCs) and human-machine interfaces (HMIs), allowing operators to adjust parameters dynamically and ensure consistent quality. Advanced sensor systems track coating thickness, surface finish, temperature, and other critical variables, enabling immediate correction if deviations occur. Inline quality inspection stations using machine vision or laser scanning further verify that each tiny component meets strict specifications before packaging or assembly.

Automation is essential not only for consistency but also for efficiency. Automated loading and unloading systems minimize manual handling, reducing the risk of contamination, loss, or damage. Robotics and conveyors move components seamlessly through the various stages, enabling high throughput without sacrificing precision. Modular designs allow manufacturers to customize and scale their lines according to production volume and product diversity, supporting both small batch prototyping and large-scale manufacturing.

Environmental controls and powder recovery systems are incorporated to minimize waste and emissions, reflecting growing industry emphasis on sustainability. Efficient filtration and powder reclamation reduce material costs and improve workplace safety by limiting airborne particles. Energy-efficient curing ovens and optimized airflow reduce power consumption and carbon footprint, aligning with green manufacturing initiatives.

Precision coating lines for tiny components are widely used across industries such as aerospace, electronics, medical devices, automotive, and precision engineering. They provide the capability to apply protective, decorative, or functional coatings—ranging from corrosion-resistant powders and insulating paints to biocompatible films and optical coatings—with unmatched repeatability and speed. By delivering flawless finishes on small, complex parts, these lines enhance product performance and reliability while enabling manufacturers to meet increasingly stringent quality standards and market demands.

In summary, a precision coating line for tiny components combines sophisticated automation, advanced coating technologies, and rigorous quality control to solve the challenges of finishing miniature parts efficiently and consistently. It is a critical investment for companies aiming to produce high-value, small-scale components with exacting surface requirements, offering improved productivity, reduced waste, and superior product quality in a competitive global market.

Precision coating lines for tiny components represent the pinnacle of manufacturing technology where every step is carefully calibrated to handle the challenges posed by small size, delicate geometries, and strict quality requirements. These lines ensure that each component, no matter how minute, receives a coating that is not only visually flawless but also functionally effective, whether that means protecting against corrosion, enhancing electrical insulation, improving wear resistance, or adding aesthetic value. The continuous movement and separation of parts during coating are crucial to avoid defects like uneven thickness, bridging, or particle clumping, which can be disastrous in applications where tolerances are tight and performance is critical.

The integration of automation reduces human error and variability, allowing manufacturers to meet tight production schedules while maintaining consistency. Handling systems like vibratory bowls or rotary drums feed the parts steadily into coating stations, while robots or conveyors transport them through cleaning, coating, curing, and inspection stages without interruption. This seamless flow increases throughput and reduces the chances of contamination or damage that might occur with manual handling. Moreover, operators can program specific coating recipes for different products or batches, switching quickly between them to accommodate varying customer needs or product lines without sacrificing quality or speed.

Advanced sensor technologies embedded throughout the line monitor key parameters in real time, including coating thickness, temperature uniformity in curing ovens, powder flow rates, and environmental conditions. If any parameter strays from its set range, the system can automatically adjust process variables or alert operators to intervene, preventing costly defects or downtime. Inline inspection using machine vision or laser scanning can detect surface imperfections or thickness inconsistencies immediately after coating or curing, allowing defective parts to be rejected or reworked before further processing.

Sustainability is increasingly integral to these precision coating lines. Efficient powder recovery systems capture and recycle overspray, minimizing waste and reducing material costs. Enclosed booths with advanced filtration protect operators from powder inhalation and prevent environmental contamination. Energy-efficient curing ovens with heat recovery features help reduce electricity consumption and carbon emissions, supporting manufacturers’ environmental compliance and sustainability goals.

Customization and scalability make precision coating lines versatile for a wide range of production needs. Small-scale manufacturers can benefit from compact, modular lines that require minimal floor space and allow rapid changeovers, while large industrial operations can deploy fully integrated, high-throughput systems capable of processing thousands of tiny components per hour. This flexibility supports innovation and responsiveness in markets where product designs and volumes frequently evolve.

Ultimately, precision coating lines for tiny components combine cutting-edge automation, material science, and quality control to provide reliable, efficient, and environmentally responsible finishing solutions. They enable manufacturers to meet the increasing demand for high-performance, miniature parts across diverse industries, ensuring that each component performs flawlessly in its final application. As technology continues to advance, these lines will incorporate even greater levels of intelligence, connectivity, and adaptability, driving the future of precision manufacturing and coating technology forward.

As precision coating lines for tiny components advance, they increasingly incorporate smart manufacturing technologies that enhance control, flexibility, and productivity. Integration with Industrial Internet of Things (IIoT) platforms allows for continuous data collection from sensors throughout the line, providing detailed insights into every aspect of the coating process. This data can be analyzed using artificial intelligence and machine learning to predict maintenance needs, optimize coating parameters, and detect quality issues before they occur, significantly reducing downtime and waste. Real-time dashboards and remote monitoring capabilities enable operators and managers to oversee multiple lines or facilities from a single interface, facilitating rapid decision-making and continuous improvement.

The use of robotics and advanced automation extends beyond material handling into areas such as adaptive coating application and precision inspection. For example, robotic spray systems equipped with vision guidance can adjust spray patterns dynamically to accommodate variations in part geometry or orientation, ensuring flawless coverage even on highly complex components. Automated inspection stations utilize high-resolution cameras, 3D laser scanners, or spectroscopic analysis to verify coating thickness, surface uniformity, and color consistency at high speeds, providing immediate feedback and quality assurance.

Emerging coating technologies, such as UV-curable powders or hybrid liquid-powder systems, are being incorporated into precision coating lines to expand their capabilities. These technologies enable faster curing cycles, lower energy consumption, and coatings with enhanced functional properties like improved adhesion, flexibility, or chemical resistance. The adaptability of modern coating lines allows manufacturers to experiment with and implement these innovations without extensive retooling, maintaining agility in a rapidly evolving market.

Sustainability remains a core focus, with continuous efforts to minimize environmental impact while maintaining productivity and quality. Advances in powder recovery and recycling systems reduce waste and raw material usage, while improved ventilation and filtration technologies protect worker health and ensure compliance with increasingly strict environmental regulations. Energy-efficient equipment designs, including ovens with optimized thermal insulation and heat recapture, contribute to reducing the overall carbon footprint of coating operations.

User experience and operational simplicity are also priorities. Intuitive touch-screen interfaces, guided maintenance prompts, and modular component design make the lines easier to operate and service, even for personnel with limited technical training. This reduces the learning curve, lowers the risk of errors, and ensures consistent performance over time.

The scalability and modularity of precision coating lines mean that manufacturers can start with smaller configurations for niche or prototype production and expand or customize their systems as demand grows or product portfolios diversify. This flexibility supports innovation, short product lifecycles, and the increasing trend toward personalized or small-batch manufacturing without compromising efficiency or quality.

In essence, precision coating lines for tiny components are becoming ever more intelligent, adaptable, and environmentally responsible. They play a vital role in enabling manufacturers to meet the stringent demands of industries like aerospace, electronics, medical devices, and automotive, where component quality, durability, and aesthetics are paramount. As these systems continue to integrate the latest technologies and innovations, they will remain indispensable assets in the competitive landscape of precision manufacturing.

Small Parts Powder Coating Equipment

Small parts powder coating equipment is specialized machinery designed to efficiently apply durable and uniform powder coatings to tiny metal or plastic components. These parts—such as screws, nuts, bolts, washers, pins, clips, and small fittings—require precise coating solutions that ensure full coverage without clumping, bridging, or missed areas, all while maintaining high production speeds and minimizing material waste. Unlike standard powder coating lines for larger items, equipment for small parts focuses on gentle handling, thorough surface exposure, and effective powder recovery to meet the unique challenges of miniature parts finishing.

The core components of small parts powder coating equipment typically include vibratory feeders or rotary baskets that gently agitate and separate the parts during coating, ensuring every surface receives equal exposure to the electrostatically charged powder particles. This motion prevents parts from sticking together and promotes uniform powder application. The powder spray is generated using electrostatic guns that impart a charge on dry powder particles, causing them to adhere to grounded parts effectively. Enclosed spray booths with efficient ventilation and filtration systems control overspray and maintain a clean working environment.

Pre-treatment modules often accompany small parts powder coating equipment to clean, degrease, and prepare the surfaces for optimal powder adhesion. Depending on the application, these modules may include ultrasonic cleaners, chemical baths, or phosphating systems designed specifically for delicate or complex small parts. Once coated, parts pass through curing ovens that provide controlled heat to melt and fuse the powder into a tough, continuous film. Curing ovens for small parts typically feature conveyors or rotating drums to ensure uniform heating and avoid part deformation or sticking.

Automation plays a significant role in these systems, with programmable logic controllers (PLCs) managing parameters such as spray duration, gun voltage, part agitation speed, and oven temperature. Automated feeding and unloading systems minimize manual handling, reducing labor costs and the risk of contamination or damage. Many systems also include powder recovery units that capture and recycle unused powder, reducing waste and lowering operating costs.

Small parts powder coating equipment is essential across industries such as electronics, automotive, aerospace, hardware manufacturing, and medical devices, where tiny components must meet high standards of corrosion resistance, electrical insulation, and aesthetic finish. By providing consistent, high-quality coatings efficiently and sustainably, this equipment enables manufacturers to improve product performance, reduce production costs, and comply with environmental regulations. The modularity and scalability of these systems allow manufacturers to tailor their setups to specific production volumes and part types, making small parts powder coating equipment a versatile and valuable asset in modern manufacturing.

Small parts powder coating equipment continues to evolve with innovations that improve precision, throughput, and sustainability. One key advancement is the refinement of part handling systems, such as vibratory feeders, rotary drums, and tumblers, which are designed to maintain gentle but consistent agitation of parts throughout the coating process. This constant movement prevents parts from sticking together and ensures that powder particles reach every surface, including intricate recesses or undercuts that are common in miniature components. The careful design of these agitation mechanisms balances effective coating with minimizing damage or wear to delicate parts.

Automation and control technologies have become increasingly sophisticated, allowing manufacturers to customize coating recipes for different parts quickly and accurately. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) enable operators to adjust variables like powder flow, electrostatic voltage, spray duration, and part rotation speed in real time. This flexibility allows quick changeovers between product batches with minimal downtime, supporting diverse production schedules and product lines. Data logging and connectivity with manufacturing execution systems (MES) support traceability and quality assurance, which are critical in regulated industries like aerospace and medical devices.

Powder recovery and filtration systems are integral components that help reduce material waste and environmental impact. These systems capture overspray powder through high-efficiency filters and cyclone separators, allowing unused powder to be reclaimed and reused. This not only lowers raw material costs but also minimizes airborne powder in the facility, improving worker safety and maintaining a clean production environment. Modern powder recovery units are designed to integrate seamlessly with coating booths and spray guns, ensuring efficient collection without interfering with the coating process.

Pre-treatment and curing processes are carefully matched to the small parts coating line to maximize adhesion and finish quality. Pre-treatment stages may include ultrasonic cleaning, chemical degreasing, or phosphating tailored to the specific materials and contaminants involved. Curing ovens feature precise temperature control and gentle handling methods—such as conveyor belts with cushioned supports or rotating baskets—to prevent part deformation during the heat curing cycle. The oven design ensures uniform heat distribution to fully melt and cure the powder coating, resulting in durable, uniform finishes.

Small parts powder coating equipment is widely used in industries requiring high-performance finishes on miniature components. In electronics, coatings provide electrical insulation and protection against moisture. In automotive and aerospace sectors, powder coatings enhance corrosion resistance and mechanical durability. Medical device manufacturers rely on biocompatible powder coatings that withstand sterilization processes. Across these industries, the equipment’s ability to consistently deliver flawless finishes on small parts at scale directly impacts product quality, reliability, and customer satisfaction.

As manufacturing trends continue toward miniaturization and increased complexity, small parts powder coating equipment will further integrate smart technologies such as real-time quality monitoring, predictive maintenance, and adaptive process controls. These innovations will drive higher productivity, lower costs, and improved environmental performance, ensuring that manufacturers can meet the evolving demands of precision coatings for small components. The combination of advanced material handling, precise powder application, effective recovery, and controlled curing makes small parts powder coating equipment an essential solution for modern manufacturing environments focused on quality, efficiency, and sustainability.

Looking ahead, the future of small parts powder coating equipment is shaped by the integration of Industry 4.0 technologies, which enable greater connectivity, automation, and data-driven decision-making. Sensors embedded throughout the coating line collect continuous data on key process parameters such as powder flow rates, electrostatic charge levels, temperature, humidity, and part movement. This data feeds into centralized control systems or cloud-based platforms where advanced analytics and machine learning algorithms identify trends, detect anomalies, and recommend optimizations. Such smart monitoring enhances process stability, reduces defects, and allows predictive maintenance schedules to be implemented, minimizing unplanned downtime and extending equipment life.

Robotics and artificial intelligence are playing an increasing role in automating part handling and quality inspection. Robotic arms equipped with vision systems can load, orient, and unload tiny components with high precision, improving throughput and reducing human error or damage. Automated inspection stations use high-resolution imaging and laser scanning to detect coating inconsistencies, thickness variations, or surface defects at high speeds, ensuring only parts that meet strict quality criteria move forward. This real-time quality control capability supports zero-defect manufacturing and helps manufacturers comply with rigorous industry standards.

Material science advancements complement equipment innovations by providing next-generation powders designed for enhanced performance. Nano-engineered powders offer superior adhesion, scratch resistance, or antimicrobial properties, while hybrid powders combine features of both powder and liquid coatings for unique functional or aesthetic effects. The ability of small parts powder coating equipment to handle these advanced powders broadens the range of applications and industries served, from medical implants to precision electronics.

Sustainability remains a strong driver for future developments. Manufacturers are increasingly adopting powder coatings free of heavy metals and other hazardous substances to meet stricter environmental regulations. Equipment designs focus on maximizing powder recovery efficiency and minimizing energy consumption through innovations like infrared curing, variable frequency drives, and optimized airflow systems. These efforts reduce operational costs and environmental footprints while improving workplace safety by limiting operator exposure to powder dust.

User experience improvements are also key, with equipment featuring intuitive touchscreens, guided maintenance alerts, and modular components that simplify operation and servicing. This reduces training requirements and helps maintain consistent process performance over time, even in high-mix, low-volume production environments.

In summary, small parts powder coating equipment is evolving into highly intelligent, flexible, and sustainable manufacturing systems. By combining advanced automation, real-time monitoring, innovative powder materials, and efficient resource use, these systems enable manufacturers to meet the growing demand for high-quality, durable coatings on tiny components. They are critical enablers in industries where precision, reliability, and environmental responsibility are paramount, and they will continue to drive innovation and competitiveness in precision manufacturing worldwide.

Compact Powder Coaters for Small Items

Compact powder coaters for small items are specialized finishing machines designed to deliver high-quality powder coating on miniature parts within a small footprint. These systems are tailored for manufacturers who need efficient, consistent, and cost-effective coating solutions but have limited floor space or lower production volumes. Ideal for coating screws, nuts, bolts, electronic connectors, jewelry components, and other small metal or plastic items, compact powder coaters combine precision application, gentle part handling, and effective powder recovery in a streamlined, user-friendly package.

Despite their reduced size, these compact systems incorporate many features found in larger industrial coaters. They typically use rotary baskets, tumblers, or vibratory feeders to agitate parts continuously during powder application, ensuring uniform coating coverage across all surfaces, including intricate details and recessed areas. Electrostatic spray guns generate a charged powder cloud that adheres efficiently to grounded parts, minimizing powder waste and overspray. Enclosed spray chambers with integrated filtration systems help contain powder particles, maintain a clean work environment, and protect operators from inhalation risks.

Compact powder coaters often include pre-treatment options such as ultrasonic cleaning or chemical degreasing modules designed to prepare delicate small parts for optimal powder adhesion. After coating, parts are conveyed into curing ovens or heated chambers with precise temperature control that ensures thorough melting and bonding of the powder without damaging sensitive components. Some compact systems utilize infra-red or convection ovens optimized for fast curing cycles in limited spaces.

Automation and control are key elements, with many compact powder coaters featuring programmable logic controllers (PLCs) and touch-screen interfaces that allow operators to set and adjust parameters like spray time, powder flow rate, agitation speed, and curing temperature. These controls enable consistent repeatability and flexibility to switch between different parts or powder types quickly. Integrated powder recovery units capture and recycle unused powder, reducing material costs and environmental impact.

The advantages of compact powder coaters include lower capital investment, reduced energy consumption, and simplified operation, making them well-suited for small to medium-sized enterprises, prototyping facilities, and manufacturers with multiple product lines requiring frequent changeovers. Their compact design also facilitates easy integration into existing production environments without significant modifications.

In industries such as electronics, medical devices, automotive components, and precision hardware manufacturing, compact powder coaters provide a practical solution to achieve durable, corrosion-resistant, and visually appealing finishes on small items. They support manufacturers in meeting stringent quality requirements while optimizing space, reducing waste, and improving operational efficiency.

In summary, compact powder coaters for small items offer a balanced combination of precision, flexibility, and efficiency within a minimal footprint. They are essential tools for manufacturers aiming to deliver consistent, high-quality powder-coated finishes on miniature components without the need for large-scale industrial equipment, enabling cost-effective production and rapid response to market demands.

Compact powder coaters for small items continue to gain popularity as manufacturers seek efficient finishing solutions that fit limited spaces and support flexible production schedules. Their design emphasizes ease of use and quick setup, enabling operators to switch between different product types or coating colors with minimal downtime. The integration of modular components, such as interchangeable baskets or feeders, further enhances versatility, allowing the system to accommodate a wide variety of small parts with diverse shapes and sizes. This adaptability is crucial in industries where product runs can be short and changeovers frequent.

Despite their smaller scale, these systems do not compromise on coating quality. The agitation methods—whether rotary tumbling, vibration, or gentle tumbling drums—ensure that each small item is evenly coated, reducing the risk of bare spots or uneven thickness that could compromise performance or aesthetics. Electrostatic powder guns are often fine-tuned to optimize powder charge and spray patterns for small parts, improving transfer efficiency and minimizing waste. Advanced filtration and powder recovery units maintain a clean working environment while recycling excess powder, supporting sustainability goals and lowering operating costs.

Compact powder coaters often feature user-friendly interfaces with programmable controls, allowing operators to set precise parameters such as powder feed rate, spray duration, part rotation speed, and curing temperature. These programmable features not only improve consistency but also facilitate rapid switching between different coatings or products, enhancing production agility. Some models include data logging capabilities, enabling manufacturers to track process parameters for quality assurance and regulatory compliance.

The curing stage in compact powder coating systems is carefully engineered to provide uniform heat distribution and gentle handling, preventing damage to sensitive or intricate small parts. Compact curing ovens may utilize infrared or convection heating, balancing fast cure times with energy efficiency. Conveyor or basket systems ensure continuous movement of parts during curing to avoid sticking and promote even coating flow and polymerization.

These compact systems are especially advantageous for small and medium-sized enterprises (SMEs), research and development labs, or specialized manufacturers who require high-quality finishing without the overhead of large industrial lines. Their relatively low capital investment and operational costs make them accessible to a broad range of users, while still delivering professional-grade coating results.

Industries such as electronics, medical devices, jewelry, automotive components, and hardware manufacturing benefit from compact powder coaters by achieving consistent, durable, and attractive finishes on small parts. The ability to produce corrosion-resistant, wear-resistant, and electrically insulating coatings enhances product performance and longevity, which is vital for customer satisfaction and competitive advantage.

Looking forward, compact powder coating equipment is expected to incorporate more intelligent automation, real-time process monitoring, and integration with digital manufacturing systems, enabling smarter, more efficient, and more sustainable finishing operations. These advancements will empower manufacturers to meet evolving market demands while optimizing resource use and maintaining high standards of quality.

In essence, compact powder coaters for small items represent a practical, efficient, and versatile solution for precision finishing needs, delivering exceptional results in a small footprint that aligns well with modern manufacturing environments focused on agility, quality, and sustainability.

Building on their growing role in precision manufacturing, compact powder coaters for small items are increasingly incorporating smart technologies that enhance automation, process control, and connectivity. Integration with Industrial Internet of Things (IIoT) platforms allows these systems to collect and analyze data from sensors monitoring powder flow, electrostatic charge, part movement, and curing conditions in real time. This connectivity enables predictive maintenance, reducing unexpected downtime, and facilitates continuous process optimization to maintain consistent coating quality.

Robotic handling solutions are becoming more common within compact systems, offering precise loading, orientation, and unloading of miniature parts. These automated material handling methods reduce manual labor, minimize the risk of part damage, and improve throughput. Advanced vision systems integrated with robotics provide real-time inspection capabilities, identifying coating defects or inconsistencies at early stages so corrections can be made promptly, improving yield and reducing waste.

The evolution of powder materials complements advances in compact coating equipment. New formulations such as ultra-fine powders, hybrid liquid-powder coatings, and functional powders with antimicrobial, anti-corrosive, or conductive properties broaden the range of achievable finishes. Compact coaters equipped to handle these advanced powders allow manufacturers to deliver highly specialized coatings that meet stringent industry standards across electronics, medical devices, aerospace, and automotive sectors.

Sustainability remains a priority, with ongoing improvements in powder recovery efficiency, energy use, and environmental controls. Equipment designs emphasize reducing powder loss and capturing overspray with enhanced filtration and cyclone systems, while curing ovens are optimized for minimal energy consumption without compromising cure quality. These efforts align with regulatory requirements and corporate sustainability goals, making compact powder coaters not only efficient but environmentally responsible.

User experience improvements continue to simplify operation and maintenance. Intuitive touchscreen interfaces, guided troubleshooting, and modular components reduce training requirements and minimize operator errors. The ability to quickly swap parts, clean equipment, and update software ensures high availability and adaptability, which is especially valuable for manufacturers handling multiple small part types or frequent product changes.

Compact powder coating systems also support lean manufacturing principles by minimizing footprint, reducing waste, and enabling just-in-time production. Their scalability allows manufacturers to start with smaller setups and expand capacity as needed without major capital investment, providing flexibility to respond to market fluctuations or new product introductions.

In summary, compact powder coaters for small items are evolving into intelligent, flexible, and sustainable finishing solutions that meet the precise demands of modern manufacturing. By combining advanced automation, innovative materials, and data-driven controls within a space-efficient design, these systems empower manufacturers to achieve superior coating quality on miniature components while optimizing productivity, cost, and environmental impact.

Automatic Powder Coating Machine for Tiny Metal Parts

An automatic powder coating machine for tiny metal parts is a purpose-built system designed to apply high-quality powder coatings to very small metal components with speed, precision, and consistency. These machines are essential in industries where large quantities of miniature parts—such as screws, nuts, bolts, clips, pins, electronic terminals, springs, and fasteners—need to be finished with protective or decorative coatings that are both durable and aesthetically uniform. Unlike manual methods, automatic machines streamline the entire process, reduce waste, and deliver repeatable results at high production volumes.

The coating process begins with careful feeding and handling of the tiny metal parts, often using vibratory bowl feeders, rotary tumblers, or perforated drums that agitate and separate the components to ensure even exposure. This movement is crucial to avoid sticking, overlapping, or clogging—common challenges when dealing with bulk tiny items. Once in motion, the parts enter an enclosed spray zone where electrostatic guns charge and disperse the powder particles. These charged particles adhere to the grounded metal surfaces, forming a uniform powder layer across all exposed surfaces.

A key advantage of automatic machines is their programmable control over all process parameters. Operators can set the powder output, spray duration, gun voltage, part agitation speed, and line speed through a digital control panel. This ensures that different part types can be coated under optimized conditions without needing manual adjustments or line reconfiguration. Such consistency is vital for manufacturers with strict quality requirements and a need for continuous, around-the-clock production.

Following the coating step, the parts are automatically transferred to a curing oven, where precise heat is applied to melt and fuse the powder into a smooth, hardened finish. Curing methods vary depending on part material and size but often include conveyorized infrared or convection ovens engineered for small items. These ovens are designed to provide even temperature distribution while preventing parts from fusing together or warping under heat.

To maximize efficiency and sustainability, most machines include integrated powder recovery systems. These systems capture unused powder from the spray zone, filter out contaminants, and return clean powder to the supply, significantly reducing material loss. This not only lowers operating costs but also minimizes the environmental impact of the process.

Automatic powder coating machines for tiny metal parts are designed to be compact yet modular, allowing manufacturers to tailor them to specific production needs. They are often integrated into larger automated lines or operated as stand-alone units for batch production. The machines are built for high durability and minimal maintenance, with features like quick-change powder hoppers, easy-to-clean spray chambers, and self-cleaning filters.

Used widely in industries such as automotive, electronics, aerospace, hardware, and medical devices, these machines play a critical role in improving product longevity, corrosion resistance, electrical insulation, and visual appeal. Their ability to handle high-speed, high-volume production of miniature components with minimal human intervention makes them an indispensable asset in modern manufacturing.