Spray Coating Machine Price: Powder coating is a dry finishing process that has become extremely popular since its introduction in the 1960s. Representing over 15% of the total industrial finishing market, powder coating is used in a wide array of products. More and more companies specify powder coatings for a high-quality, durable finish, allowing for maximized production, improved efficiencies, and simplified environmental compliance. The process involves applying a free-flowing, dry powder to a substrate, which is then cured under heat to form a solid, durable layer. Unlike traditional liquid paint, powder coating does not require a solvent, making it an eco-friendly option with minimal volatile organic compound (VOC) emissions.

The powder used in this process is a mixture of finely ground particles of pigment and resin. Once sprayed onto a surface, the powder coating is baked in a curing oven, causing the powder to melt and flow into a uniform film. The result is a smooth, consistent, and durable finish that is resistant to chipping, scratching, and fading. This makes powder coating an ideal choice for products exposed to harsh environmental conditions, such as automotive parts, outdoor furniture, and industrial machinery.

Market Demand and Applications

The demand for powder coating has seen significant growth due to its numerous advantages over traditional liquid coatings. The automotive industry, for instance, utilizes powder coating for both decorative and protective purposes. The ability to produce high-quality finishes that are resistant to corrosion, wear, and UV radiation makes powder coating an attractive option for manufacturing car parts. Similarly, the appliance industry relies on powder coatings for their ability to provide durable and aesthetically pleasing finishes on household items like refrigerators, washing machines, and stoves.

In the architectural sector, powder coatings are widely used for aluminum extrusions and other metal components due to their ability to withstand outdoor conditions without deteriorating. The growing emphasis on eco-friendly manufacturing processes has also driven demand for powder coating in the furniture industry, where it is used on metal frames and other components. Additionally, the electronics industry benefits from powder coating’s insulating properties, which make it ideal for coating electrical enclosures and components.

Key Components and Processes

A powder coating system is made up of several key components that work together to achieve a high-quality finish. The process typically begins with surface preparation, which is critical for ensuring good adhesion of the powder coating. Surface preparation may involve cleaning, sandblasting, or chemical treatments, depending on the material being coated. The prepared surface is then moved to a spray booth, where an electrostatic spray gun applies the powder. The electrostatic charge helps the powder particles adhere to the substrate uniformly.

Once the powder is applied, the coated item is moved to a curing oven, where it is exposed to heat, typically between 160°C and 210°C. The heat causes the powder to melt and flow, forming a continuous film that bonds to the substrate. Curing times vary depending on the type of powder used and the thickness of the coating. After curing, the item is cooled, inspected, and ready for use.

Key components of a powder coating system include:

- Powder Coat Line: A conveyor system that moves parts through each stage of the process.

- Spray Booth: A controlled environment where the powder is applied.

- Curing Oven: An oven designed to heat the coated parts, allowing the powder to cure and bond.

- Filtration Systems: Equipment that captures and recycles overspray, improving efficiency and reducing waste.

Advancements in powder coating technology have led to the development of more sophisticated systems that offer greater precision, faster processing times, and improved energy efficiency. For instance, modern curing ovens are designed to minimize energy consumption while providing consistent heat distribution, ensuring uniform curing of the powder coating. Additionally, automated powder coating lines have become increasingly common, allowing for higher production rates and reduced labor costs.

Powder Coat Line and its Importance

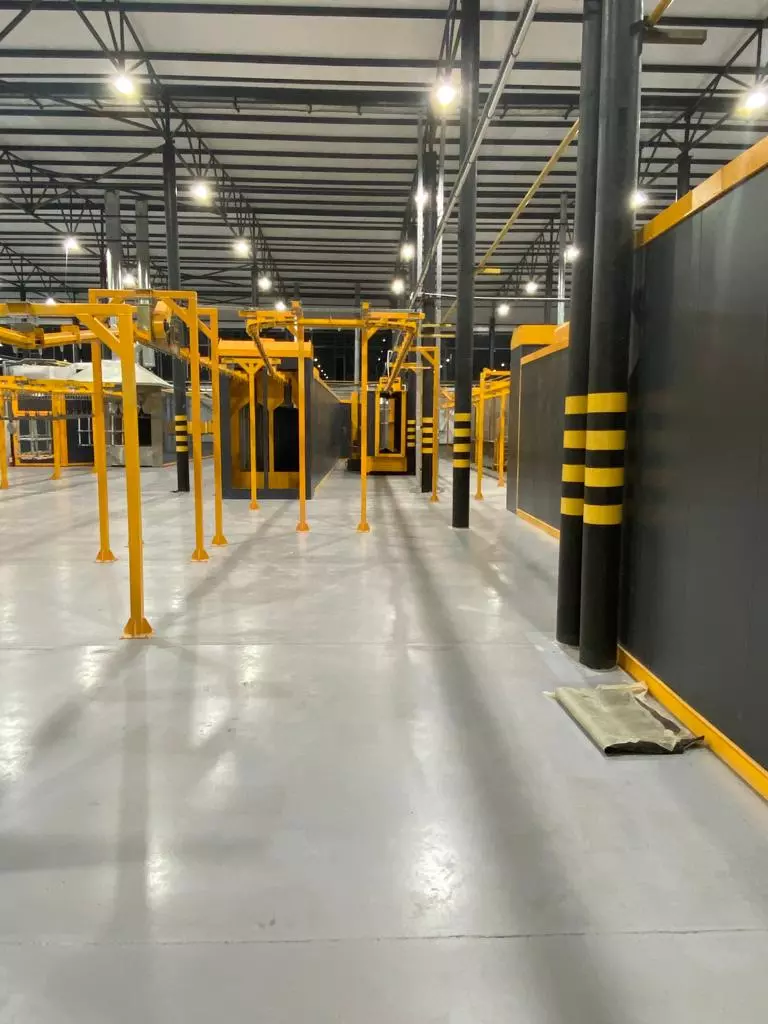

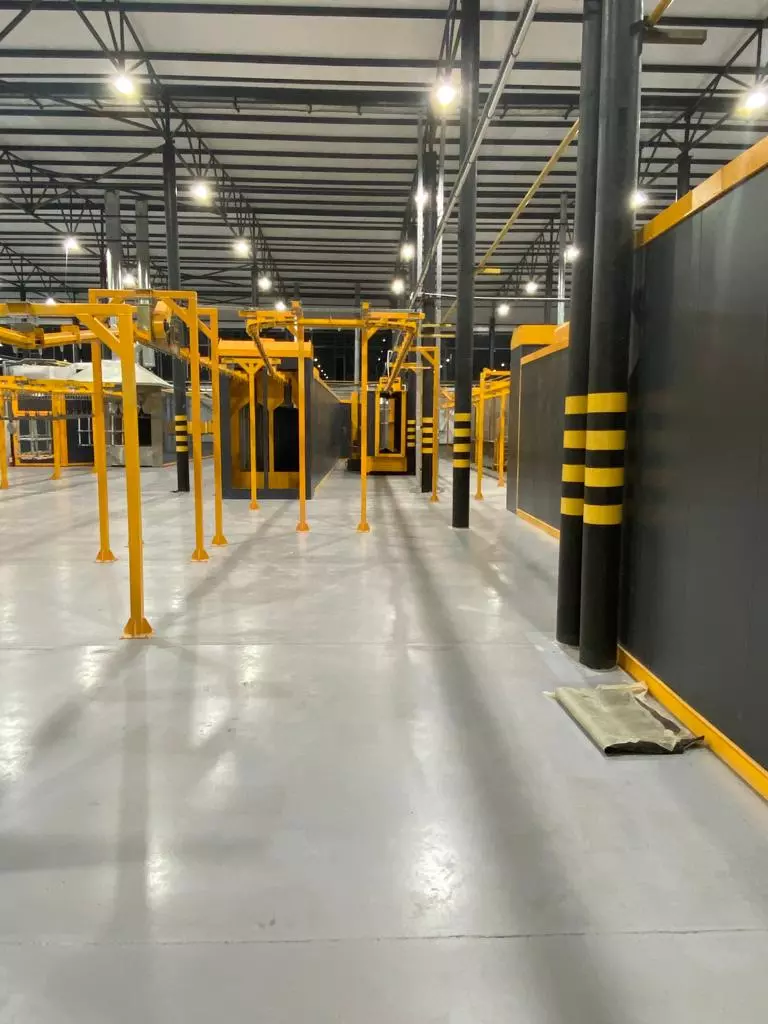

A powder coat line is the backbone of any powder coating operation, serving as the integrated system that moves parts through each stage of the powder coating process. The design and setup of the powder coat line are critical to achieving high-quality finishes and ensuring efficient production. Typically, a powder coat line includes a series of interconnected components such as conveyors, spray booths, curing ovens, and pretreatment stations. These elements work together to ensure that each part is consistently coated and cured to the desired specifications.

The process begins with surface preparation, where parts are cleaned and pre-treated to remove contaminants that could affect coating adhesion. Following pretreatment, the parts are conveyed to the spray booth, where the powder is applied using electrostatic spray guns. The coated parts are then transferred to a curing oven, where the powder is melted and bonded to the surface. Finally, the finished parts are cooled and inspected before being removed from the line.

Components of a Powder Coat Line

- Conveyor System: The conveyor system is the backbone of the powder coat line, responsible for transporting parts through each stage of the process. Conveyor systems can be designed in various configurations, such as overhead conveyors, floor-mounted systems, or chain-driven conveyors. The choice of conveyor depends on factors such as the size and weight of the parts, production speed, and available space. Wheel-mounted conveyors are commonly used for their flexibility and ability to handle heavy loads.

- Spray Booth: The spray booth is where the powder coating is applied to the parts. It is designed to contain the powder overspray and prevent contamination of the surrounding environment. Modern spray booths are equipped with advanced filtration systems to capture and recycle overspray, improving material efficiency and reducing waste. Automated paint booths are also common, allowing for precise and consistent application of powder coatings.

- Curing Oven: After the powder has been applied, the coated parts are moved to a curing oven. The curing oven is designed to heat the parts to a specific temperature, typically between 160°C and 210°C, causing the powder to melt and form a uniform, durable coating. Various types of curing ovens are available, including gas/oil curing ovens, electric ovens, and diesel heating curing ovens. The choice of oven depends on factors such as energy availability, production volume, and coating specifications.

- Pretreatment Station: The pretreatment station is where parts undergo cleaning and surface preparation before coating. Common pretreatment processes include zinc phosphating, degreasing, and sandblasting. Proper pretreatment is essential for achieving strong adhesion between the coating and the substrate, as well as ensuring the longevity of the finished product.

- Filtration System: Filtration systems are crucial for capturing and recycling powder overspray, ensuring that the powder coat line operates efficiently and with minimal waste. Pleated filter materials are commonly used in filtration systems due to their high surface area and ability to capture fine particles.

Automation and Efficiency

The integration of automation in powder coat lines has revolutionized the industry, leading to significant improvements in productivity, consistency, and cost-effectiveness. Automated systems are capable of precisely controlling the application of powder coatings, ensuring uniform thickness and coverage. This level of precision is particularly important in industries where consistent quality is critical, such as automotive and aerospace manufacturing.

Automated powder coat lines also reduce the need for manual labor, minimizing the risk of human error and lowering operational costs. Advanced monitoring systems can track various parameters, such as temperature, conveyor speed, and powder usage, allowing for real-time adjustments to optimize the coating process. Additionally, automation enables faster production speeds, allowing manufacturers to meet high-volume demands without compromising on quality.

Powder Coating Applications

Industrial Applications

Powder coating plays a pivotal role in a wide range of industrial applications, offering a durable and protective finish to products exposed to extreme environmental conditions, mechanical stress, or corrosive materials. One of the most prominent sectors utilizing powder coating is the automotive industry, where it is used extensively for coating vehicle frames, engine components, suspension parts, and even wheels. The automotive industry benefits from powder coating due to its superior resistance to corrosion, abrasion, and UV radiation. This leads to longer-lasting finishes, reduced maintenance, and enhanced aesthetic appeal.

In the aerospace sector, powder coating is employed to protect aircraft components from corrosion and mechanical wear. The high durability of powder-coated surfaces ensures that they can withstand the extreme conditions experienced during flight, including drastic temperature changes, high speeds, and exposure to chemical agents. Moreover, powder coating adds minimal weight to components, an important consideration for aerospace applications.

The consumer goods industry also extensively uses powder coating for products such as bicycles, household appliances, and outdoor furniture. Powder coating on appliances like refrigerators, ovens, and washing machines provides a smooth, glossy, and durable finish that is highly resistant to scratching and chipping. It also enhances the appearance of these products, making them more attractive to consumers. In addition, manufacturers of outdoor furniture favor powder coating due to its ability to withstand harsh weather conditions, including intense sunlight, rain, and humidity, without fading or degrading.

Another significant area of application is the construction and architectural industry. Powder coating is widely used on aluminum extrusions, window frames, door frames, and other metal building components. Architectural applications benefit from powder coating’s ability to withstand UV radiation and provide long-lasting protection against corrosion, making it suitable for both interior and exterior elements.

Specialty Coatings

Powder coating is not limited to metal surfaces but extends to other materials and specialty applications. Glass coating has become increasingly popular in architectural and automotive applications. Glass surfaces can be powder coated to enhance durability, create a decorative finish, or improve energy efficiency by providing additional insulation properties. In particular, glass coating factories utilize specialized systems to apply a consistent powder coat, which is cured and bonded to the glass for long-lasting performance.

Another key application is aluminum powder coating, which is essential for products that require lightweight yet strong protection. The appliance manufacturing industry is a major consumer of aluminum powder coating for items such as washer and dryer panels, kitchen ranges, and small appliances. Aluminum powder coating not only provides an attractive finish but also protects the substrate from oxidation and corrosion.

In pharmaceutical and beverage industries, bottle coating machines are used to apply protective coatings to glass and plastic bottles. Powder coating ensures that bottles are resistant to scratches and impacts during handling and transportation. This has become particularly relevant in the packaging industry where product integrity is paramount.

Environmental Impact and Sustainability

One of the driving forces behind the increased adoption of powder coating is its positive environmental impact compared to traditional liquid paint. Powder coating is free of solvents and volatile organic compounds (VOCs), which are harmful to the environment and human health. VOCs contribute to air pollution and have been linked to various health issues. Powder coating’s lack of VOC emissions makes it a greener alternative, aligning with stringent environmental regulations and the growing demand for sustainable manufacturing processes.

Powder coating systems are designed to optimize material usage, reducing waste. Any overspray during the application process can be captured and recycled, resulting in near-zero waste. This contributes to lower costs and minimizes the environmental footprint of manufacturing operations.

Moreover, powder coating’s durability reduces the need for frequent repainting or replacement of coated products. This not only extends the lifespan of finished products but also decreases resource consumption and waste generation over time. As industries move towards greener practices, powder coating’s combination of performance, cost-effectiveness, and sustainability will continue to drive its widespread adoption across various sectors.

Powder Filters and Filtration Systems

Importance of Filtration in Powder Coating

In powder coating operations, the filtration system plays a crucial role in maintaining the efficiency, quality, and safety of the process. Effective filtration is necessary to capture and manage the overspray generated during the application of powder coatings. Overspray, if not properly filtered, can lead to wastage of materials, contamination of the work environment, and potential health hazards for workers. Additionally, unfiltered overspray can settle on freshly coated surfaces, compromising the quality and uniformity of the finish. Thus, a robust filtration system is integral to achieving high-quality results and maintaining an efficient powder coating line.

Types of Powder Filters

Powder coating systems typically incorporate various types of filters to manage and reclaim overspray, ensuring the coating process is both economical and environmentally responsible. The main types of powder filters include:

- Pleated Filter Materials: These filters are commonly used in powder coating systems due to their large surface area, which allows for efficient capture of fine powder particles. Pleated filters are typically made of materials such as polyester, which is durable and resistant to clogging. The pleated design increases the filter’s capacity to hold powder particles, reducing the frequency of filter changes and maintenance.

- Cartridge Filters: Cartridge filters are cylindrical and can be installed in spray booths to capture overspray directly. These filters are often made of materials that provide high efficiency in capturing even the smallest powder particles. They are easy to replace and can be reused after cleaning, making them a cost-effective option for powder coating operations.

- HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are used in situations where extremely fine filtration is required, particularly in environments where air quality is critical. HEPA filters can capture particles as small as 0.3 microns with 99.97% efficiency, ensuring that the air exiting the filtration system is free of harmful particulates.

- Powder Reclamation Machines: These machines are designed to collect and recycle overspray, which can then be reintroduced into the coating process. Reclamation systems significantly reduce material waste and improve the cost-efficiency of the powder coating operation. They are particularly valuable in high-volume production environments where large amounts of powder are used.

Maintenance and Efficiency

Maintaining the filtration system is vital for ensuring continuous operation and avoiding disruptions in the powder coating process. Regular inspection and replacement of filters are necessary to prevent clogs and ensure that the filtration system operates at peak efficiency. Clogged filters can lead to reduced airflow, which can negatively impact the application of powder and the overall quality of the coating.

Efficient filtration systems not only improve the quality of the finished product but also contribute to the sustainability of the powder coating operation. By effectively capturing and recycling overspray, companies can reduce their environmental footprint and lower the cost of raw materials. Moreover, proper maintenance of filtration systems extends the life of the equipment, reducing the need for frequent replacements and minimizing downtime.

Advanced filtration technologies have further enhanced the efficiency of powder coating operations. For example, some modern systems incorporate automatic filter cleaning mechanisms that reduce maintenance requirements and ensure consistent performance. By optimizing the filtration process, companies can achieve higher productivity, better quality control, and greater environmental compliance.

Spray Booths in Powder Coating

Design and Functionality of Spray Booths

Spray booths are an essential component of any powder coating operation, providing a controlled environment where the powder is applied to parts or products. The primary function of a spray booth is to contain the powder overspray and ensure that it is properly managed, either by filtering and reclaiming it or by safely exhausting it from the workspace. The design of the spray booth is critical in achieving consistent coating quality, maintaining a clean working environment, and optimizing material usage.

Spray booths are typically constructed from durable materials such as steel and are equipped with ventilation and filtration systems to manage airflow and capture overspray. The booth is designed to create a controlled airflow that directs the overspray towards the filtration system, preventing it from settling on the coated parts or escaping into the surrounding area. This not only ensures a high-quality finish but also protects workers from inhaling powder particles.

There are various types of spray booths, including open-front booths, enclosed booths, and booths with integrated conveyor systems. The choice of booth depends on factors such as the size and shape of the parts being coated, the volume of production, and the specific requirements of the coating process. Enclosed booths, for example, are ideal for high-volume production environments where minimizing contamination is critical. On the other hand, open-front booths are more commonly used in smaller operations or for coating larger parts that require manual handling.

Spray Coating Machines

Within the spray booth, the application of powder is carried out using spray coating machines, which can be either manual or automated. Manual spray guns are operated by technicians who control the flow and direction of the powder, making them ideal for coating complex shapes or small production runs. These guns use electrostatic forces to attract the powder particles to the part, ensuring even coverage and minimizing waste.

Automated spray coating machines, on the other hand, are designed for high-volume production and consistent application. These machines are often integrated with robotic arms or reciprocators that move the spray guns along predefined paths, ensuring uniform coverage on all surfaces of the part. Automated systems are particularly beneficial in industries where precision and repeatability are critical, such as automotive or aerospace manufacturing.

Automated paint booths often include multiple spray guns and advanced control systems that can adjust the application parameters in real-time. This allows for precise control over the thickness of the coating, reducing the likelihood of defects such as orange peel or uneven coverage. Additionally, automated systems can be programmed to apply multiple layers of coating, each with different properties, in a single pass.

Safety and Compliance

Operating a spray booth involves managing several safety and regulatory concerns. Since powder coatings are typically flammable in their airborne state, the design and operation of the spray booth must adhere to strict safety standards to prevent accidents. This includes ensuring proper ventilation to prevent the accumulation of powder in the air, which could lead to explosive conditions.

Furthermore, spray booths must be equipped with fire suppression systems, such as automatic sprinklers or fire extinguishers, to quickly address any fire hazards. Workers must also be provided with personal protective equipment (PPE), including respirators, gloves, and protective clothing, to minimize exposure to powder particles and chemicals used in the coating process.

In addition to safety, spray booths must comply with environmental regulations that govern emissions and waste management. Filtration systems in the booth are responsible for capturing and treating the powder overspray, ensuring that harmful particulates do not escape into the atmosphere. Some advanced filtration systems include HEPA filters, which can capture extremely fine particles, ensuring that the air leaving the booth is clean and free of contaminants.

Regular inspections and maintenance of spray booths are essential to ensure ongoing compliance with safety and environmental regulations. This includes checking the integrity of the filtration systems, ensuring proper airflow, and verifying the functionality of fire suppression systems.

Pre-Treatment for Powder Coatings

Necessity of Pre-Treatment

Pre-treatment is a critical step in the powder coating process, as it significantly influences the adhesion, durability, and overall quality of the final coating. The primary purpose of pre-treatment is to clean and prepare the surface of the substrate, removing contaminants such as oils, grease, dirt, and oxidation. Without proper pre-treatment, these contaminants can interfere with the adhesion of the powder, leading to issues such as poor coverage, flaking, and reduced resistance to environmental factors.

In addition to cleaning, pre-treatment also often involves the application of a conversion coating, which provides a chemically active surface that enhances the bonding of the powder coating. This step is particularly important for substrates that are prone to corrosion, such as steel and aluminum. The conversion coating acts as a protective layer, improving the substrate’s resistance to rust and other forms of degradation.

Pre-treatment is especially crucial in industries where products are exposed to harsh environments, such as automotive, aerospace, and outdoor furniture manufacturing. For these applications, the pre-treatment process ensures that the powder coating provides long-lasting protection against corrosion, wear, and UV radiation.

Common Pre-Treatment Processes

Several pre-treatment methods are used in powder coating, each suited to different materials and application requirements. The choice of pre-treatment process depends on factors such as the type of substrate, the desired properties of the final coating, and the specific environmental conditions the coated part will face.

- Phosphate Coating Process: Phosphating is one of the most common pre-treatment methods used for steel and other ferrous metals. This process involves applying a phosphate solution to the metal surface, which reacts with the substrate to form a layer of crystalline phosphates. This layer not only improves adhesion but also provides a degree of corrosion protection. Zinc phosphating is particularly popular due to its superior corrosion resistance compared to other types of phosphating.

- Degreasing and Cleaning: Before any chemical pre-treatment, it is essential to remove oils, grease, and other contaminants from the surface. This is typically done using aqueous cleaning solutions or solvents, followed by rinsing to ensure that no residue remains. In some cases, a dip pre-treatment plant is used, where parts are immersed in cleaning and rinsing baths to ensure thorough surface preparation.

- Etching: For aluminum and other non-ferrous metals, etching is a common pre-treatment process. This involves using acidic solutions to remove the oxide layer on the metal surface, creating a roughened texture that enhances the mechanical bonding of the powder coating. Etching is often followed by a passivation step, where a chemical solution is applied to further protect the metal from corrosion.

- Sandblasting: Sandblasting is a mechanical pre-treatment process that uses abrasive particles propelled at high speed to clean and roughen the surface of the substrate. This method is particularly effective for removing rust, scale, and old coatings, making it suitable for refurbishing parts. Sandblasting also creates an ideal surface profile for powder coating, ensuring strong adhesion.

- Chemical Conversion Coatings: In addition to phosphating, other chemical conversion coatings such as chromating and anodizing are used for specific applications. Chromating is commonly used for aluminum, providing excellent corrosion resistance and a good surface for powder coating. Anodizing, another process for aluminum, involves creating a thick oxide layer that is highly resistant to corrosion and wear.

Challenges and Solutions

Despite its importance, the pre-treatment process can present several challenges, particularly in large-scale or automated production environments. One common issue is the inconsistent application of pre-treatment chemicals, which can lead to variations in coating quality. This can be addressed by using automated pre-treatment systems that ensure precise dosing and uniform application across all parts.

Another challenge is the disposal of waste generated during the pre-treatment process, such as spent chemicals and rinse water. To minimize environmental impact and comply with regulations, many facilities incorporate waste treatment systems that neutralize and filter effluents before disposal.

Proper maintenance of pre-treatment equipment is essential to avoid process disruptions and ensure consistent quality. Regular inspection and cleaning of tanks, nozzles, and filtration systems can prevent issues such as clogged lines or contaminated baths, which could compromise the effectiveness of the pre-treatment.

Aluminium Powder Coating

Specifics of Aluminium Powder Coating

Aluminium powder coating is a specialized process tailored to the unique properties of aluminum, a lightweight, durable, and corrosion-resistant metal widely used in industries ranging from automotive to construction. Although aluminum naturally forms a protective oxide layer that prevents corrosion, powder coating provides an additional layer of protection and enhances the aesthetic appeal of aluminum products.

One of the key challenges in aluminum powder coating is achieving strong adhesion between the powder and the substrate. Aluminum’s smooth surface and natural oxide layer can make it difficult for the powder to bond effectively. Therefore, proper surface preparation is essential to ensure long-lasting adhesion and prevent issues such as peeling or flaking.

Another consideration is the thermal sensitivity of aluminum. Since powder coating requires curing at high temperatures, it’s important to control the curing process to prevent warping or other thermal deformations of aluminum parts, especially those with thin walls or intricate designs.

Applications in Industry

Aluminium powder coating is used extensively across various industries due to its excellent balance of strength, weight, and corrosion resistance. In the architectural sector, aluminum powder coating is commonly applied to window frames, door frames, curtain walls, and other building components. The coating not only protects these elements from environmental factors but also offers a wide range of color and finish options, allowing architects and designers to achieve the desired aesthetic for both interior and exterior applications.

In the automotive industry, aluminum components such as wheels, trims, and engine parts are often powder-coated to enhance their durability and resistance to harsh road conditions. The lightweight nature of aluminum, combined with the protective properties of powder coating, makes it ideal for reducing the overall weight of vehicles while maintaining high performance and longevity.

The consumer goods industry also benefits from aluminum powder coating, particularly in the production of household appliances, outdoor furniture, and sports equipment. For example, aluminum frames of bicycles and outdoor furniture are powder-coated to prevent corrosion and wear, ensuring that these products can withstand prolonged exposure to the elements.

Additionally, electronics and electrical industries use aluminum powder coating to protect components from environmental exposure and electrical interference. Coated aluminum parts, such as heat sinks and enclosures, benefit from enhanced thermal conductivity and electrical insulation, improving the performance and safety of electronic devices.

Machinery and Techniques

The process of aluminum powder coating typically involves several key steps to ensure a high-quality finish. After surface preparation, which may include etching and anodizing to enhance adhesion, the aluminum parts are transported to a spray booth where an electrostatic spray gun applies the powder. The charged powder particles adhere uniformly to the surface, forming a smooth and even layer.

Once coated, the parts are moved to a curing oven, where they are heated to a temperature that melts the powder and allows it to flow into a continuous film. Careful control of the curing process is critical, as aluminum’s thermal properties require precise temperature management to avoid any deformation.

The choice of powder coating equipment, including professional powder coating machines and automated systems, is crucial in achieving consistent results. Advances in technology have led to more sophisticated equipment that offers better control, efficiency, and adaptability to different production environments.

Powder Coating Transport Systems

Role of Conveyors and Transport Systems

In a powder coating operation, the transport system plays a crucial role in moving parts through various stages of the process, including surface preparation, powder application, and curing. Efficient transport systems ensure smooth and continuous production flow, minimizing downtime and enhancing overall productivity. These systems are designed to handle various types of parts, from small components to large assemblies, and can be customized to meet specific production needs.

Conveyors are the most common form of transport in powder coating lines. They move parts along the production line, ensuring that each part progresses through the necessary steps in a timely and organized manner. The design and layout of the conveyor system are critical, as they determine the efficiency of the entire powder coating process. Properly designed conveyor systems can significantly reduce labor costs, improve throughput, and ensure consistent quality by maintaining a controlled process environment.

Types of Transport Systems

Several types of transport systems are used in powder coating operations, each offering unique advantages depending on the application and production requirements:

- Wheel-Mounted Conveyors: These are flexible conveyor systems that can be easily adapted to different production layouts. Wheel-mounted conveyors are ideal for handling heavy loads and are often used in applications where parts need to be transported over long distances or through complex pathways. They are commonly found in automotive and industrial manufacturing environments.

- Overhead Conveyors: Overhead conveyors are widely used in powder coating lines due to their ability to save floor space and accommodate large or awkwardly shaped parts. These conveyors are suspended from the ceiling, allowing parts to be transported above the production floor, freeing up space for other equipment and activities. Overhead conveyors are particularly useful in high-volume production settings, where efficient use of space is essential.

- Chain-Driven Conveyors: Chain-driven conveyors are robust systems designed to handle heavy-duty parts and assemblies. These conveyors use chains to move parts along the line, providing a stable and reliable transport mechanism. Chain-driven conveyors are often used in applications where parts must be precisely positioned or where continuous operation is required.

- Automated Transport Systems: Automation in transport systems can significantly enhance the efficiency and flexibility of powder coating operations. Automated systems can be programmed to adjust speed, direction, and timing, ensuring that parts arrive at each stage of the process exactly when needed. This level of control is particularly beneficial in complex or high-mix production environments where different parts require different processing times.

Optimizing Transport Efficiency

To optimize the efficiency of powder coating transport systems, several factors must be considered, including the layout of the production line, the type of parts being coated, and the desired production speed. Proper alignment and synchronization of the conveyor system with other components, such as spray booths and curing ovens, are essential for maintaining a smooth and efficient workflow.

Regular maintenance and monitoring of the transport system are also critical to preventing breakdowns and ensuring consistent performance. This includes inspecting conveyor chains, wheels, and motors, as well as addressing any issues with alignment or tension.

Powder Coating Machines and Equipment

Overview of Powder Coating Machines

Powder coating machines are the heart of the powder coating process, responsible for applying the powder to substrates and ensuring that the coating adheres uniformly and effectively. These machines vary widely in design, complexity, and application, ranging from simple manual systems to highly sophisticated automated setups. The choice of equipment depends on factors such as the type of product being coated, production volume, and specific finish requirements.

Powder coating machines can be categorized into several types, each designed for specific applications:

- Manual Powder Coating Guns: These are handheld devices used by operators to manually apply powder to the substrate. They are ideal for small-scale operations or when coating complex or intricate parts that require precise control. Manual powder coating guns allow the operator to adjust the spray pattern, flow rate, and electrostatic charge to ensure even coverage, making them versatile tools for custom or low-volume production runs.

- Automated Powder Coating Machines: Automated systems are used in high-volume production environments where consistency and speed are critical. These machines typically include robotic arms or reciprocators that move the spray guns along pre-programmed paths. Automated systems ensure uniform application of the powder coating across all parts, reducing the likelihood of defects such as uneven thickness or missed areas. They are particularly beneficial in industries such as automotive and industrial manufacturing, where large quantities of parts need to be coated with precision.

- Professional Powder Coating Machines: These machines are designed for industrial-scale operations and are often part of a fully integrated powder coating line. Professional powder coating machines include advanced features such as real-time monitoring of powder usage, automated color changes, and sophisticated control systems that optimize the coating process for different substrates and products. These machines are capable of handling large volumes of work, making them ideal for manufacturers with high production demands.

Professional and Industrial Equipment

Professional and industrial powder coating machines are engineered to handle the rigors of large-scale manufacturing. These machines often include multiple spray booths, conveyor systems, and curing ovens, all integrated into a seamless production line. The goal is to maximize efficiency, reduce waste, and ensure consistent, high-quality finishes across all parts.

In industrial settings, powder coating machines are equipped with advanced control systems that allow for precise adjustments to the coating process. These systems can monitor variables such as electrostatic charge, powder flow rate, and environmental conditions within the spray booth, making real-time adjustments to maintain optimal coating conditions. This level of control is essential in industries where product specifications are stringent, and any deviation from the required coating thickness or uniformity could lead to product failure.

Automated powder coating machines often feature multiple spray guns that can be configured to apply different types of coatings in a single pass. This capability is particularly useful in industries where parts require multiple layers of coating, such as a primer, color coat, and topcoat. Automated systems can be programmed to apply these layers with precise timing and thickness, ensuring a high-quality finish that meets or exceeds industry standards.

Innovations and New Technologies

The powder coating industry has seen significant technological advancements in recent years, leading to the development of more efficient, flexible, and environmentally friendly equipment. Some of the key innovations include:

- High-Efficiency Powder Coating Guns: Newer models of powder coating guns are designed to improve transfer efficiency, reducing the amount of overspray and material waste. These guns use advanced electrostatic technology to ensure that more powder adheres to the substrate, resulting in a smoother finish and reduced need for touch-ups or rework.

- Rapid Color Change Systems: In industries where multiple colors are used, rapid color change systems have become increasingly popular. These systems allow operators to switch between colors quickly and efficiently, minimizing downtime and reducing the risk of contamination between colors. This is particularly useful in industries such as automotive or consumer goods, where custom colors are often required.

- Energy-Efficient Curing Ovens: Advances in curing oven technology have led to the development of more energy-efficient systems that reduce operating costs and environmental impact. Modern ovens use advanced heating elements and insulation materials to achieve faster curing times at lower temperatures, without compromising the quality of the finish. Some systems also incorporate real-time monitoring and control of oven temperatures, ensuring consistent curing conditions across all parts.

- Automated Inspection Systems: Quality control is a critical aspect of powder coating operations, and automated inspection systems are becoming more common in industrial settings. These systems use sensors and cameras to inspect coated parts for defects such as uneven thickness, missed areas, or contaminants. Automated inspection systems can quickly identify and flag issues, allowing for immediate corrective action and reducing the risk of defective products reaching the customer.

- Eco-Friendly Powder Coating Systems: Environmental considerations are increasingly important in the manufacturing industry, and powder coating is no exception. Newer powder coating systems are designed to minimize environmental impact by reducing energy consumption, material waste, and VOC emissions. Some systems also incorporate powder reclamation technology, which captures and recycles overspray, further reducing waste and improving cost efficiency.

Suppliers and Manufacturers

The market for powder coating machines is diverse, with many manufacturers offering a wide range of equipment to meet the needs of different industries. Some of the leading suppliers of powder coating machines include global companies with a strong presence in major manufacturing hubs, such as the powder coating machine industry in Dubai. Dubai has emerged as a key player in the global powder coating market, thanks to its strategic location, advanced infrastructure, and growing demand for high-quality coatings in the Middle East.

Manufacturers in Dubai and other global centers offer a variety of powder coating machines, from small-scale manual systems to fully automated industrial lines. These suppliers often provide not only the equipment but also comprehensive support services, including installation, training, and maintenance, ensuring that customers can achieve optimal performance from their powder coating systems.

Curing Ovens in Powder Coating

Types of Curing Ovens

Curing ovens are a fundamental component in the powder coating process, responsible for heating the powder-coated parts to a specific temperature, allowing the powder to melt, flow, and bond to the substrate, forming a durable and uniform finish. The type of curing oven used can significantly impact the quality of the finish, energy consumption, and overall efficiency of the coating process.

There are several types of curing ovens commonly used in powder coating operations:

- Gas/Oil Curing Ovens: These ovens are heated by burning natural gas or oil, making them a cost-effective option for many industrial operations. Gas and oil ovens are particularly suitable for large-scale production environments due to their ability to maintain consistent temperatures over long periods. They are widely used in industries such as automotive, where large parts or assemblies require uniform heating. Gas-powered ovens are preferred in regions where natural gas is readily available and cost-effective, whereas oil-fired ovens might be used in locations where oil is more accessible or affordable.

- Electric Curing Ovens: Electric ovens are powered by electricity and are known for their precise temperature control, making them ideal for applications where temperature consistency is critical. These ovens are typically used in smaller or more specialized operations where energy efficiency and precise control over the curing process are essential. Electric ovens are also easier to install and maintain compared to gas or oil ovens, as they do not require a complex fuel delivery system.

- Diesel Heating Curing Ovens: Diesel heating ovens are another option, particularly in regions where diesel fuel is more accessible or economical. These ovens offer similar benefits to gas and oil ovens in terms of consistent heating but are typically used in environments where other fuel sources are less practical. Diesel ovens are also portable, making them suitable for temporary or mobile powder coating operations.

- Benchtop Curing Ovens: For small-scale or laboratory applications, benchtop curing ovens provide a compact and efficient solution. These ovens are used for curing small batches of parts or for testing new coatings and processes. Benchtop ovens offer precise control and are ideal for environments where space is limited, or the volume of production is low.

- Pleated Filter Material Curing Conveyor Ovens: These specialized curing ovens are designed for continuous production lines where parts are moved through the oven on a conveyor system. The pleated filter material is often used to manage airflow and ensure that the curing environment remains consistent. These ovens are typically found in high-volume production environments where efficiency and consistency are paramount.

Functionality and Design

The design and functionality of curing ovens are critical to the success of the powder coating process. A well-designed curing oven ensures that the powder coating is heated evenly, which is essential for achieving a smooth, uniform finish. Uneven heating can result in defects such as orange peel, poor adhesion, or incomplete curing, all of which can compromise the durability and appearance of the finished product.

Curing ovens are designed to maintain a consistent temperature throughout the curing chamber. This is achieved through a combination of insulation, airflow management, and precise temperature control systems. In a typical powder coating operation, the curing oven will operate at temperatures ranging from 160°C to 210°C, depending on the specific powder being used and the substrate material.

The airflow within the curing oven is carefully managed to ensure that heat is evenly distributed across all parts. This is particularly important in conveyor ovens, where parts are continuously moving through the oven chamber. Airflow is typically controlled using fans and ductwork that direct heated air towards the parts while also removing excess heat and exhaust gases.

Energy efficiency is another critical consideration in the design of curing ovens. Modern ovens are equipped with advanced insulation materials that minimize heat loss, reducing the overall energy consumption of the powder coating operation. Some ovens also feature energy recovery systems that capture and reuse waste heat, further improving efficiency.

Manufacturers and Suppliers

Choosing the right curing oven requires careful consideration of the specific needs of the powder coating operation, including the type of parts being coated, the production volume, and the available energy sources. Several manufacturers and suppliers specialize in providing curing ovens tailored to different industrial requirements.

Leading gas/oil curing oven manufacturers and suppliers offer a range of products designed to meet the demands of various industries. These suppliers provide not only the ovens but also installation, maintenance, and support services to ensure that the ovens operate efficiently and reliably.

Suppliers of electric curing ovens often focus on providing high-precision equipment suitable for specialized applications. These ovens are commonly used in industries where small batch production or specialized coatings require tight control over the curing process.

Manufacturers of diesel heating curing ovens typically cater to regions where diesel fuel is the preferred energy source. These suppliers offer ovens that are designed to be robust, portable, and capable of operating in challenging environments.

Paint Circulation Systems

Role in Powder Coating

In powder coating operations, paint circulation systems play a crucial role in ensuring the consistent delivery of powder to the spray guns, maintaining uniform coating quality across all parts. These systems are designed to continuously circulate powder through the coating equipment, preventing settling, maintaining the right powder consistency, and ensuring that the spray guns receive a steady supply of material. Proper circulation is essential for achieving a smooth, even finish and for minimizing waste and operational downtime.

Paint circulation systems are especially important in high-volume production environments, where large quantities of powder are used, and any interruption in the supply can result in costly delays. By keeping the powder in constant motion, these systems help maintain a consistent flow rate and ensure that the powder remains homogenous, reducing the likelihood of defects in the finished product.

Design Considerations

The design of a paint circulation system depends on several factors, including the type of powder being used, the size and layout of the powder coating operation, and the specific requirements of the coating process. Key components of a paint circulation system typically include:

- Storage Hopper: The storage hopper holds the bulk supply of powder and is designed to keep the powder in an agitated state, preventing it from clumping or settling. The hopper is connected to the circulation system, ensuring a continuous supply of powder to the spray guns.

- Pumps and Piping: Pumps are used to move the powder from the hopper through a network of pipes to the spray guns. The piping system is designed to minimize friction and prevent powder buildup, which can lead to blockages or inconsistent flow rates.

- Filters: Filters are integrated into the circulation system to remove contaminants and ensure that only clean, dry powder reaches the spray guns. This is particularly important in maintaining the quality of the finish, as any impurities in the powder can cause defects.

- Recirculation Lines: Excess powder that is not deposited on the part during the spraying process is typically recaptured and returned to the hopper through recirculation lines. This helps to reduce waste and improve the overall efficiency of the powder coating operation.

Challenges and Solutions

One of the main challenges in paint circulation systems is maintaining a consistent powder flow, especially in large or complex systems. Variations in powder flow can lead to uneven coating thickness, poor adhesion, and other quality issues. To address this, modern circulation systems are equipped with sensors and control systems that monitor the flow rate and adjust the pump speed and pressure as needed.

Another challenge is preventing powder buildup in the piping system, which can lead to blockages and disrupt the coating process. Regular maintenance, including cleaning and inspection of the piping and pumps, is essential to prevent these issues and ensure reliable operation.

Surface Coating Machines and Systems

Overview of Surface Coating Machines

Surface coating machines are essential in various industrial processes where materials, parts, or products require protective or decorative finishes. These machines apply coatings such as paint, powder, or specialized films to surfaces, ensuring that they meet specific functional or aesthetic requirements. Surface coating machines are used across many industries, including automotive, aerospace, electronics, and construction, where they help improve the durability, appearance, and performance of products.

The surface coating process can involve different types of coatings, each with its own set of machines and equipment. Whether it’s applying a protective layer to prevent corrosion, adding a decorative finish, or creating a surface with specific electrical or thermal properties, the choice of machine and coating process is critical to achieving the desired outcome.

Industrial Paint Systems

Industrial paint systems are a key category of surface coating machines, designed for applying liquid coatings such as paints, varnishes, or lacquers to a wide range of substrates. These systems are typically used in large-scale manufacturing environments, where high-volume production and consistent quality are essential.

- Spray Coating Machines: These machines use air pressure or electrostatic charges to atomize the paint and apply it to the surface. Spray coating machines can be manual or automated, depending on the production requirements. Automated systems are often integrated with robotic arms for precise application, ensuring uniform coverage and minimizing waste.

- Dip Coating Machines: In dip coating, parts are immersed in a tank of liquid coating material and then removed, allowing excess coating to drain off. This method is particularly effective for coating parts with complex geometries or for applying thick layers of material. Dip coating machines are commonly used for products that require a high level of corrosion resistance, such as automotive parts and metal fixtures.

- Electrostatic Coating Systems: Electrostatic coating systems use an electrical charge to attract the coating material to the substrate, ensuring even coverage and reducing overspray. This technique is highly efficient and is often used in industries where precise coating thickness and minimal waste are important.

- Conveyorized Paint Lines: Conveyorized paint lines are used in large-scale production environments where parts are moved through the coating process on a conveyor system. These lines typically include pre-treatment stations, spray booths, curing ovens, and cooling areas, allowing for continuous production and high throughput.

Technological Advancements

Recent technological advancements in surface coating machines have focused on improving efficiency, precision, and environmental sustainability. Innovations in machine design and control systems have led to significant improvements in the quality and consistency of coatings, as well as reductions in waste and energy consumption.

- Automated Control Systems: Modern surface coating machines are often equipped with advanced control systems that monitor and adjust key process parameters in real-time. These systems can control variables such as spray pressure, coating thickness, and curing time, ensuring that each part is coated to exact specifications. Automated control systems also help reduce the need for manual intervention, increasing production speed and reducing the likelihood of human error.

- High-Precision Coating Technologies: New coating technologies, such as plasma coating and nano-coating, have expanded the range of applications for surface coating machines. These technologies allow for the application of ultra-thin, highly uniform coatings that can provide enhanced properties, such as increased hardness, improved wear resistance, or superior electrical insulation.

- Energy-Efficient Systems: Energy efficiency is a growing concern in the industrial sector, and surface coating machines are no exception. Recent developments have focused on reducing the energy consumption of coating processes, such as optimizing curing oven designs and using low-energy application methods. These advancements help manufacturers lower operating costs and meet increasingly stringent environmental regulations.

Maintenance and Efficiency

Maintaining surface coating machines is essential for ensuring consistent quality and prolonging the lifespan of the equipment. Regular maintenance activities include cleaning nozzles and filters, checking and replacing worn parts, and calibrating control systems. Proper maintenance helps prevent issues such as clogs, uneven coatings, and machine downtime, which can disrupt production and lead to increased costs.

In addition to regular maintenance, investing in high-quality, durable coating machines can improve efficiency and reduce the total cost of ownership. Machines that are designed for ease of use and quick changeovers can help manufacturers adapt to different production requirements and reduce downtime between batches.

Glass Coating Industry Overview

Importance of Glass Coating

Glass coating plays a crucial role in enhancing the functionality, durability, and aesthetic appeal of glass products. Coatings applied to glass surfaces can provide a range of benefits, including improved energy efficiency, increased strength, reduced glare, and enhanced privacy. The glass coating industry serves various sectors, including architecture, automotive, electronics, and consumer goods, where the performance and appearance of glass are of paramount importance.

In the architectural sector, coated glass is widely used in windows, facades, and skylights to improve energy efficiency and reduce the need for artificial heating and cooling. Coatings such as low-emissivity (Low-E) coatings reflect heat while allowing natural light to pass through, helping buildings maintain a comfortable indoor temperature. Similarly, in the automotive industry, glass coatings are applied to windshields and windows to reduce glare, enhance UV protection, and improve visibility in various weather conditions.

The electronics industry also benefits from glass coatings, particularly in the production of screens for smartphones, tablets, and televisions. Anti-reflective and anti-smudge coatings are commonly applied to improve visibility and durability. Additionally, specialized coatings such as conductive or anti-static coatings are used in devices that require specific electrical properties.

Coating Processes for Glass

The process of applying coatings to glass involves several techniques, each tailored to achieve specific results based on the intended application. The choice of coating process depends on factors such as the type of glass, the desired coating properties, and the production volume.

- Sputtering: Sputtering is a physical vapor deposition (PVD) process used to apply thin films of material onto the glass surface. This process involves bombarding a target material with high-energy particles, causing atoms to be ejected and deposited onto the glass. Sputtering is commonly used for applying Low-E coatings, reflective coatings, and anti-reflective coatings. It allows for precise control over the thickness and uniformity of the coating, making it ideal for high-performance glass products.

- Chemical Vapor Deposition (CVD): In the CVD process, a chemical reaction occurs on the glass surface, forming a thin film coating. This technique is often used to apply hard coatings, such as those that enhance scratch resistance or reduce glare. CVD coatings are typically durable and can be applied to large glass surfaces, making them suitable for architectural and automotive applications.

- Dip Coating: Dip coating involves immersing the glass in a solution containing the coating material, followed by controlled withdrawal to achieve a uniform film. This method is commonly used for applying anti-fog, anti-scratch, and decorative coatings. Dip coating is a versatile process that can be adapted to different glass shapes and sizes, making it a popular choice for both industrial and consumer applications.

- Spray Coating: Spray coating involves atomizing the coating material into a fine mist and applying it to the glass surface. This method is particularly useful for large or complex glass surfaces where uniform coverage is essential. Spray coating is commonly used in the production of automotive glass, architectural glass, and electronic displays. Advanced spray coating systems, such as those used in glass spray coating systems, ensure precise application and minimal waste.

Factories and Manufacturing

The glass coating industry is supported by a network of specialized factories and manufacturing facilities that produce coated glass products for various applications. These facilities are equipped with state-of-the-art coating machines and systems designed to handle large volumes of glass with precision and efficiency.

Glass coating factories typically include multiple coating lines, each dedicated to a specific type of coating process. For example, a factory may have separate lines for sputtering, CVD, and spray coating, allowing it to produce a wide range of coated glass products. These factories are often located in close proximity to glass manufacturers, enabling efficient supply chain management and reducing transportation costs.

Coated glass factories play a vital role in meeting the growing demand for high-performance glass products in both domestic and international markets. These factories are often equipped with advanced quality control systems to ensure that each piece of glass meets stringent industry standards. This includes testing for properties such as light transmission, thermal insulation, and scratch resistance.

Powder Coating Plant Setup and Management (600 words)

Setting Up a Powder Coating Plant

Setting up a powder coating plant involves careful planning, substantial investment, and a clear understanding of the processes involved. The first step in establishing a powder coating plant is selecting a suitable location. The plant’s location should provide ample space for all necessary equipment and allow for future expansion as production demands grow. Accessibility to suppliers, customers, and a skilled labor force is also essential.

The layout of the powder coating plant is a critical aspect of its setup. An efficient layout minimizes material handling, reduces the risk of contamination, and ensures a smooth workflow from pre-treatment to coating and curing. The plant should be divided into distinct areas for surface preparation, coating application, curing, and inspection. Additionally, proper ventilation and dust control systems must be in place to maintain a clean and safe working environment.

Selecting the right equipment is another crucial step. The plant requires several key components, including spray booths, curing ovens, conveyors, and filtration systems. Each piece of equipment should be chosen based on the type of products being coated, the volume of production, and the specific requirements of the powder coating process. For example, industries dealing with large, heavy parts may need wheel-mounted conveyors or specialized ovens that can handle the weight and size of these components.

Equipment and Infrastructure

The core of a powder coating plant’s infrastructure consists of the following equipment:

- Pre-Treatment Systems: Pre-treatment is essential for ensuring proper adhesion and durability of the powder coating. The plant must have a dedicated area for cleaning, degreasing, and applying chemical treatments like phosphating or chromating. Depending on the scale of operations, pre-treatment can be done using manual spray systems or automated dip tanks.

- Spray Booths: The spray booth is where the powder coating is applied. It must be designed to contain overspray and provide a clean, controlled environment for application. Automated spray booths are often equipped with multiple guns and advanced controls to ensure consistent coverage. For larger operations, automated paint booths are recommended to increase throughput and improve coating uniformity.

- Curing Ovens: The curing oven is where the powder coating is melted and fused to the substrate. The oven must be capable of maintaining a consistent temperature to ensure proper curing. Depending on the energy source, the plant may use gas, oil, electric, or diesel heating curing ovens. Each type has its advantages, with gas and oil ovens being cost-effective for large operations, while electric ovens offer precise temperature control.

- Conveyors and Transport Systems: Conveyors are essential for moving parts through each stage of the coating process. The design of the conveyor system should be tailored to the plant’s layout and the specific needs of the production line. Wheel-mounted conveyors or overhead conveyors are commonly used in larger plants, while smaller operations may use simple chain-driven systems.

- Filtration and Recovery Systems: Filtration systems are necessary for capturing overspray and maintaining air quality in the plant. These systems also allow for the recovery and reuse of powder, reducing waste and improving cost efficiency. Powder reclamation machines are often integrated into spray booths to collect and recycle overspray.

Operational Challenges

Managing a powder coating plant involves addressing several operational challenges to ensure efficiency, quality, and profitability. One common challenge is maintaining consistent production quality. Variations in coating thickness, curing temperature, or surface preparation can lead to defects and rework. Implementing strict quality control measures and regular equipment maintenance can help mitigate these issues.

Another challenge is managing environmental compliance. Powder coating plants must adhere to regulations regarding air emissions, waste disposal, and worker safety. Investing in proper filtration systems, waste treatment facilities, and safety training can help the plant remain compliant with local and international standards.

Energy consumption is also a significant concern, particularly in large-scale operations. The curing ovens, in particular, are energy-intensive. To reduce energy costs, many plants are adopting energy-efficient technologies, such as insulated ovens and energy recovery systems that capture and reuse waste heat.

Conclusion

Setting up and managing a powder coating plant requires a strategic approach to ensure the facility is efficient, compliant, and capable of producing high-quality products. By carefully planning the layout, selecting appropriate equipment, and addressing operational challenges, businesses can establish a successful powder coating operation that meets the demands of their industry.

Industry-Specific Applications and Equipment

Appliance Manufacture Coatings

In the appliance manufacturing industry, powder coatings are extensively used to enhance the durability, appearance, and performance of household appliances. Products like refrigerators, washing machines, ovens, and dishwashers benefit from the application of powder coatings, which provide a smooth, uniform finish that is resistant to scratches, chips, and corrosion. The high durability of powder coatings is particularly important for appliances that undergo frequent use and exposure to moisture, heat, and cleaning chemicals.

The appliance industry often uses specialized powder coatings that offer additional properties such as anti-fingerprint, antimicrobial, and heat resistance. For example, powder coatings with antimicrobial properties are increasingly popular for appliances like refrigerators and washing machines, where hygiene is a key concern. These coatings inhibit the growth of bacteria and fungi, ensuring that surfaces remain clean and safe over extended periods.

To meet the specific needs of the appliance industry, manufacturers utilize professional powder coating machines designed for high-volume production. These machines are capable of applying coatings with consistent thickness and finish, ensuring that every appliance meets the same high standards of quality.

Automotive Powder Coating

The automotive industry relies heavily on powder coatings for both aesthetic and protective purposes. Powder coatings are used on a wide range of automotive components, including wheels, engine parts, chassis, and body panels. The ability of powder coatings to withstand harsh environmental conditions, such as exposure to road salt, UV radiation, and extreme temperatures, makes them ideal for automotive applications.

In addition to protection, powder coatings contribute to the appearance of vehicles by providing a high-gloss, durable finish. Automotive manufacturers often use automated powder coating systems to apply multiple layers of coatings, including primers, color coats, and clear coats, in a single, efficient process. These systems ensure that each layer is applied with precision, resulting in a flawless finish that enhances the vehicle’s aesthetic appeal and longevity.

Advanced technologies such as rapid color change systems are particularly useful in the automotive industry, where manufacturers must frequently switch between different colors and finishes. These systems minimize downtime and reduce the risk of contamination between colors, improving overall production efficiency.

Coating Machine Parts and Components

The performance of powder coating systems depends heavily on the quality and condition of their parts and components. Coating machine parts, including nozzles, spray guns, pumps, and filters, must be regularly maintained and replaced to ensure consistent coating quality and prevent production interruptions. Using high-quality, durable components is essential for maintaining the efficiency and reliability of powder coating operations.

Suppliers offer a wide range of replacement parts for powder coating machines, including those specifically designed for well-known brands like Nordson. These parts are engineered to meet the exact specifications of the original equipment, ensuring a perfect fit and optimal performance. Regular maintenance and timely replacement of worn parts help prevent issues such as uneven coating application, equipment breakdowns, and increased operational costs.

Innovative Powder Equipment

The powder coating industry is continually evolving, with new equipment and technologies emerging to address the changing needs of various industries. Innovative powder equipment includes advanced automation systems, energy-efficient curing ovens, and high-efficiency powder coating guns that reduce material waste and improve coating quality. These innovations help manufacturers stay competitive by enhancing production efficiency, reducing environmental impact, and improving the quality of finished products.

Investing in the latest powder coating technology can provide a significant competitive advantage, enabling manufacturers to produce high-quality coatings faster and more cost-effectively. As industries continue to demand more specialized and high-performance coatings, the development and adoption of innovative powder equipment will remain a key driver of growth in the powder coating sector.

Conclusion

Summary of Powder Coating Industry

The powder coating industry has established itself as a critical component in modern manufacturing, offering a durable, efficient, and environmentally friendly alternative to traditional liquid coatings. With applications spanning various sectors—from automotive and aerospace to consumer goods and architecture—powder coating has become the preferred choice for manufacturers seeking high-quality finishes that withstand the rigors of daily use and harsh environmental conditions.

Powder coating systems are composed of several key elements, including spray booths, curing ovens, conveyors, and filtration systems, each contributing to the overall efficiency and quality of the coating process. The industry has seen significant advancements in technology, leading to the development of automated systems, high-efficiency equipment, and eco-friendly solutions that meet the evolving demands of global markets.

Future Trends and Innovations

As the industry continues to grow, future trends are likely to focus on further improving efficiency, reducing environmental impact, and expanding the range of applications for powder coatings. Innovations such as energy-efficient curing ovens, rapid color change systems, and advanced powder reclamation technologies will play a crucial role in driving the industry forward. Additionally, the development of new powder formulations that offer enhanced properties, such as antimicrobial resistance, increased durability, and specialized finishes, will open up new possibilities for powder coating applications.

The integration of smart manufacturing technologies, including the Internet of Things (IoT) and advanced data analytics, is expected to enhance the precision and control of powder coating processes. These technologies will enable real-time monitoring and optimization of production lines, reducing waste, improving product quality, and increasing overall operational efficiency.

Final Thoughts

The powder coating industry is at the forefront of sustainable manufacturing, offering solutions that not only meet stringent quality standards but also align with global efforts to reduce environmental impact. As industries continue to prioritize durability, aesthetics, and eco-friendliness in their products, the demand for powder coating solutions is set to rise.

For businesses involved in manufacturing, investing in the latest powder coating technologies and equipment is essential to maintaining a competitive edge. By embracing innovation and continuously improving processes, manufacturers can ensure that they meet the demands of today’s market while positioning themselves for future growth.

In conclusion, powder coating remains a vital and dynamic industry, with ongoing advancements that promise to deliver even greater efficiency, sustainability, and versatility in the years to come.

Not only do we manufacture our powder coating equipment, we also ship them worldwide to your facility with care

We’re not just the manufacturers of your powder coating equipment, we’re also your worldwide delivery partners.

At EMS Powder Coating Equipment, we understand that getting your powder coating equipment to you quickly and safely is just as important as manufacturing it to the highest standards. That’s why we offer worldwide delivery services to all of our customers.

We work with a network of experienced and reliable shipping partners to ensure that your equipment arrives on time and in perfect condition. We also offer a variety of shipping options to fit your budget and needs.

Whether you need your equipment shipped to a local address or to an international destination, we can help. We’ll work with you to choose the best shipping option for your needs and to keep you updated on the status of your shipment every step of the way.

So when you choose EMS for your powder coating equipment, you’re not just getting the best products on the market, you’re also getting the best possible delivery experience.

Contact us today to learn more about our worldwide delivery services.