When you do powder coating, you need to control the quality. Here you can find more information about powder coating quality control and its options.

Powder coating is increasingly accepted as the preferred finishing process for many applications. Increasingly stringent environmental regulations, rising costs in all areas, and demands by consumers for better quality and more durable products are among the challenges facing today’s finishers. Powder coatings provide a solution to these challenges and others. Powder coating is the technique of applying dry paint to the component.

The powdered paint is normally applied by using a powder feed system and gun to electrostatically charge and spray the powder onto the part. For some applications, the part being coated is dipped into a fluidized bed of powder. The coated part is then heated in an oven, or via infrared panels, to melt and cure the paint. During the curing process, a chemical cross-linking reaction is triggered and it is this chemical reaction that gives the powder coatings many of their desirable properties.

Options for Powder Coating Quality Control

Ensuring consistent and high-quality powder coating results requires a comprehensive approach to quality control. Several techniques and methodologies can be employed to monitor and evaluate the powder coating process throughout its stages.

Pre-Coating Inspection

- Surface Preparation: Verify that the substrate is properly cleaned, degreased, and phosphated to ensure optimal adhesion of the powder coating.

- Pretreatment Consistency: Monitor the consistency of the pretreatment process, ensuring that the substrate receives the correct treatment time, temperature, and chemical concentration.

- Substrate Defects: Inspect the substrate for any defects or imperfections that could affect the powder coating finish, such as scratches, dents, or rust.

Powder Application

- Powder Quality: Evaluate the quality of the powder, ensuring it is free from contaminants and has the correct particle size distribution for the application.

- Electrostatic Spray Parameters: Monitor the electrostatic spray parameters, such as gun voltage, air pressure, and powder feed rate, to ensure consistent and uniform powder application.

- Powder Thickness: Measure the powder thickness on the substrate using a film thickness gauge to ensure it within the specified range for the desired finish.

Curing

- Oven Temperature: Monitor and control the oven temperature throughout the curing cycle to ensure the powder particles properly melt, fuse, and crosslink.

- Curing Time: Maintain the specified curing time to ensure complete curing of the powder coating.

- Oven Atmosphere: Monitor the oven atmosphere, particularly oxygen levels, to prevent oxidation or discoloration of the powder coating.

Post-Coating Inspection

- Film Adhesion: Perform adhesion tests, such as tape tests or cross-cut tests, to assess the adhesion of the powder coating to the substrate.

- Film Appearance: Inspect the powder coating finish for defects such as orange peel, fisheyes, or uneven gloss.

- Film Thickness: Measure the final film thickness to ensure it complies with the specified requirements.

- Film Hardness: Perform hardness tests to evaluate the durability and scratch resistance of the powder coating finish.

- Color Consistency: Compare the color of the powder coating finish to the desired color standard.

Additional Quality Control Measures

- Statistical Process Control (SPC): Implement SPC techniques to track and analyze powder coating process parameters and identify potential variations.

- Laboratory Testing: Conduct laboratory tests on powder samples and coated substrates to evaluate properties such as corrosion resistance, UV resistance, and chemical resistance.

- Visual Inspection: Train personnel to conduct thorough visual inspections of the powder coating finish to identify and address defects promptly.

- Continuous Improvement: Establish a culture of continuous improvement by regularly reviewing quality control data, identifying areas for improvement, and implementing corrective actions.

- Documentation: Maintain comprehensive records of quality control procedures, inspection results, and corrective actions to ensure traceability and continuous learning.

By implementing these quality control measures, powder coating operations can achieve consistent, high-quality results, enhance product durability and aesthetics, and maintain customer satisfaction.

Salt Spray Testing (FOG)

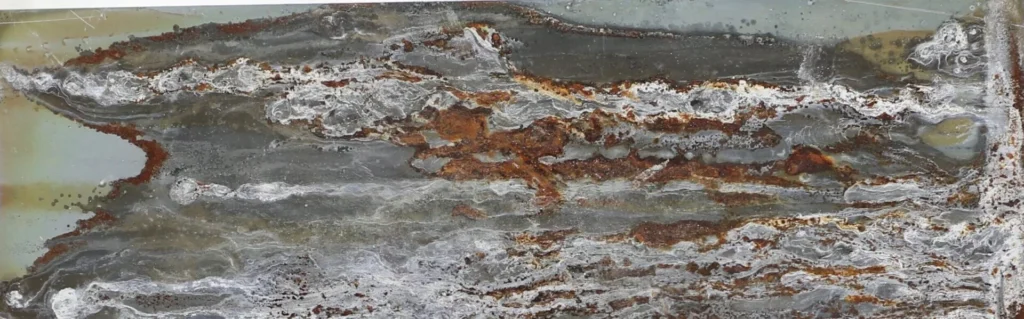

Salt Spray (FOG) Testing involves submitting test pieces, parts, or panels (coupons) to a precisely-controlled accelerated corrosive environment (a salt spray cabinet) to evaluate the relative corrosion resistance of the coating or part. Because the environment inside the cabinet is warm, moist, and a little bit salty, it’s almost like taking your car to the beach for a few months to see how much it will rust.

Although no direct correlation can be made between a number of hours in Salt Spray and a number of hours, days, or years in the real world (or other media before corrosion, the test has been used as a standard for evaluation of the corrosion resistant properties of coatings for many years. Alike in many ways, Salt Spray testing is generally considered more extreme than High Humidity testing.

There are many standard specifications detailing cabinet parameters, length of time in the cabinet, evaluation of corrosion, and the amount of allowable corrosion per part per test length, including military, commercial and industrial specs. Some of the very common Salt Spray tests are run to confirm MIL-C-5541/BAC5719 for chromate conversion coating. MIL-A-8625/BAC 5019 for anodizing and TT-C-490 for phosphating and paint.

We also have a great deal of experience in assisting customers with designing a set of parameters to meet individual research or production needs.

In addition to the above applications, Salt Spray can also be used to evaluate the performance of assembled electronic equipment. Ashley Laboratories Ltd. maintains a cabinet conforming to ASTM B-117 (latest revision 365 days a year. Our turnaround is rapid, parts often go into the cabinet the same day they are received, parts are evaluated the same day testing is completed and reports are quickly generated. Most tests run for intervals of 24 hours.

We are an approved vendor for Salt Spray testing of the Boeing Corporation (insert Boeing link here www.boeing.com) and others. We offer individual attention to our wide base of clients from across the globe.

High Humidity Testing

High Humidity Testing, like Salt Spray (FOG) Testing, is a form of evaluating coatings or electronic equipment performance, after exposure to a precisely-controlled accelerated environment. Unlike Salt Spray, the cabinet generally maintains a moist and warm environment, but without the additional corrosively of the salt. For that reason, High Humidity is generally considered a bit less harsh a test than Salt Spray.

Both the temperature and the relative humidity of the cabinet are adjusted to conform to the desired specification for which parts are to be tested. There are many standard specifications detailing cabinet parameters, length of time in the cabinet, evaluation of corrosion, and the amount of allowable corrosion per part per test length, including military, commercial and industrial. Some common High Humidity tests are run to conform to ASTM A 380/QQ-P-35, WS 16198, BAC 5751, and Mil Std 753.

We also have a great deal of experience in assisting with designing a set of parameters to meet your individual research or production needs. Our turnaround is rapid; parts often go into the cabinet the same day they are received, parts are evaluated the same day testing is completed and reports are quickly generated. Most tests run for either a few hours or intervals of 24 hours

Solution Analysis in powder coating quality control

Solution analysis is one of the essential services for powder coating quality control. Whether you need regular checks for solution control or specific analyses to assure compliance with specification requirements analysts provide quick, careful, and accurate attention to all your solution analysis needs.

With our vast experience and background, we can assist you with solution analyses from the most routine daily, weekly, or monthly solution controls for in-house quality requirements to quality system procedures to support the needs of the FAA, NASA, or the aerospace industry from periodic checks against in-house testing kit types of analyses to individually designed research projects.

Waste Water Analysis / Environmental Testing

In our effort to offer comprehensive soup-to-nuts service for our customers, Ashley Laboratories Ltd. offers a full range of wastewater, effluent, and other environmental testing to meet your wastewater discharge permit needs and more. We have built a wide range of clients from all manner of metal finishers (job shop platers, aircraft engine and landing gear refurbishes, pc board manufacturers, machine shops, etc) to

soft drink bottlers from bakeries and laundries to real estate auction houses.

Look to Ashley first for your Fed EPA, state or local regulatory permit-required effluent testing, in-house studies of your waste treatment systems, TCLP leachate testing, and other environmental service. All tests performed were in accordance with current EPA-approved methods (including 40 CFR part 136, 600-4-79-020). Our rigorous quality program includes in-house and EPA round-robin blind studies.

Abrasion resistance (Taber) Testing

Abrasion resistance (Taber) testing is a regulated wear test used to evaluate the durability of coatings and materials. Most commonly associated, in our industry, with hard coat anodize (MIL-A_8625, type) this test is internationally recognized for its accuracy and reliability as an indication of the quality of a wear-resistant coating.

A coated test panel (or section of material) is weighed, then rotated and abraded by specially designed grit-embedded wheels for a specific number of cycles (the aforementioned MIL-A-8625 requires 10,000 cycles) and weighed again to determine coating weight loss and/or wear index.

Ashley Laboratories Ltd. provides regular testing to the existing specifications. We also have and will gladly assist in designing individual research projects for new or experimental coatings.

Adhesion Testing in powder coating quality control

Metal finishing has a wide variety of adhesion testing from the ability of a plated coating to stick to the substrate to a painted surface’s integrity to the reliability of aerospace parts to maintain a tenacious adherence between the substrate, and a chromate conversion coating, and the primer and paint layers. Ashley Laboratories Ltd. offers the full gamut of adhesion testing: wet tape, dry tape bend, knife, crosshatch, scribe, etc.

Knife Test

This simple test requires the use of a utility knife to pick at the coating. It establishes whether the adhesion of a coating to a substrate or to another coating (in multi-coat systems) is at a generally adequate level. Performance is based on both the degree of difficulty to remove the coating from the substrate and the size of the removed coating. Using the knife and cutting guide, two cuts are made into the coating with a 30-45 degree angle between the legs and down to the substrate which intersects to form an “X”.

At the vertex, the point of the knife is used to attempt to lift up the coating from the substrate or from the coating below. This is a highly subjective test and its value depends upon the inspector’s experience. A coating that has a high degree of cohesive strength may appear to have worse adhesion than one which is brittle and hence fractures easily when

probed. There is no known correlation to other adhesion test methods (pull-off, pate, etc.)

Tape Test

On metal substrates, a more formal version of the knife test is the tape test. Pressure-sensitive tape is applied and removed over cuts made in the coating. There are two variants of this test; the X-cut tape test and the cross hatch tape test. The X-cut tape test is primarily intended for use at job sites.

Using a sharp razor blade, scalpel, knife, or another cutting device, two cuts are made into the coating with a 30-45 degree angle between the legs and down to the substrate which intersects to form an “X”. Steel or other hard mental straightedge is used to ensure straight cuts. Tape is placed in the center of the intersection of the cuts and then removed rapidly. The X-cut area is then inspected for removal of coating and rated.

The cross-hatch tape test is primarily intended for use in the laboratory on coating less than 5 miles (125 microns) thick. It uses a cross-hatch pattern rather than the X pattern. A cutting guide or a special cross-hatch cutter with multiple preset blades is needed to make sure the incisions are properly spaced and parallel. After the tape has been applied and pulled off, the cut area is then inspected and rated.

Pull-off Tests

A more quantitative test for adhesion is pull-off where a loading fixture, commonly called a dolly or stub, is affixed by an adhesive to a coating. By use of a portable pull-off adhesion tester, a load is increasingly applied to the surface until the dolly is pulled off. The force required to pull the dolly off or the force the dolly withstood, yields the tensile strength in pounds per square inch (psi) or mega system comprised of the dolly, adhesive, coating system, and substrate, and will be exposed by the fracture surface.

This test method maximizes tensile stress as compared to the shear stress applies by another method, such as a scrape or knife adhesion, and results may not be comparable. Further, pull-off strength measurements depend upon the instrument used in the test. Results obtained using different devices or results for the same coating on substrates having different stiffness may not be comparable.

Solder Ability Testing in powder coating quality control

Solderability testing is performed to assure the ability of the coated parts to be soldered successfully in assembly for electronic performance. Ashley Laboratories offers solder ability testing to individual coating specifications such as MIL-T-10727 and QQ-S-365 or for broader test method standards such as MIL-STD-202 method 208. Following strictly scripted laboratory procedures, we test actual parts or test coupons, per your requirement, to these and other rigorous standards.

Porosity Testing

Ashley Laboratories, Ltd. also offers porosity testing in our full line of testing procedures for coated products. As its name implies, porosity testing assesses the integrity of the coated surface, by revealing holes or pores in the coating. A common porosity test is the peroxyl test for chromium coatings as detailed in QQ-C-320. Other tests are also available.

DeFelsko manufactures instruments that measure the thickness of powder coating on a variety of substrates before or after cure. This article describes measurement solutions and lists appropriate ASTM testing documents.

Overview

Thickness measurement of powder can be taken before and after curing. Substrate type, thickness range, part shape, and economics determine the best method to be employed. For uncured applied powders, height measurement can be performed with powder combs and with magnetic gages employing special powder probes. These techniques are destructive and may require recoating the part.

Coating powders generally diminish in thickness during the curing process so these procedures require a reduction factor be determined to predict cured firm thickness. Ultrasonic instruments also measure uncured powder but do so without touching the surface. Instead of measuring powder height, they automatically display a predicted cured thickness result. For after–cure measurement, a variety of handheld instruments are available.

These non-destructive instruments employ either magnetic, eddy current or ultrasonic principles depending on the substrate. The less common methods include micrometer measurement and destructive dry film methods such as cross-sectioning and gravimetric (mass) measurement.

Measurement after curing

We begin with a discussion of post-cure measurement simply because cured thickness targets are the value most often supplied by both powder manufacturing and coating specifies. Dry film thickness (DFT) instruments are common, affordable, non-destructive, and easy to operate. They employ magnetic, eddy current or ultrasonic principles depending on the substrate

Three principles of operation are employed. A magnetic principle is used to measure non-magnetic coating on steel parts for the other metal, an eddy current principle is used provides the coating is non-conductive. For non-metals, an ultrasonic principle is used.

Magnetic Gages – Mechanical

When the parts of steel, measurements are made with a magnetic thickness gauge using either mechanical or electronic operation. Mechanical pull-off gages use a permanent magnet. Cured thickness is determined

by measuring the force required to pull that magnet from the coated steel surface.

Magnetic pull-off gages are rugged, simple, inexpensive, portable, and usually do not require any calibration adjustment.They are a good, low-cost alternative in situations where quality goals require only a few readings during production. Defelsko manufactures two mechanical instruments. The PosiTest FM is a rollback dial model comprised of a magnet attached to one end of a pivoting balance arm and connected to a calibrated hairspring.

By rotating the dial with a finger, the spring increases the force on the magnet and pulls it from the surface. It is safe in explosive environments and is commonly used by painting contractors and smell powder coating operations .mlt has a tolerance of ±5%.

Pencil-type models like our PosiPen use a magnet this is mounted to a helical spring that works perpendicularly to the coated surface. Ideal for small parts or for quick quality checks, the controller has a smaller probe tip allowing it to be placed with pinpoint accuracy on small parts, hard-to-reach areas, and curved surfaces. The temperature range of -100 to 230 ºC (-150 to 450º F) makes it ideal for taking measurements on hot parts fresh out of the oven. It has a tolerance of ± 10%

Electronic Instruments for powder coating quality control

A variety of electronic instruments are available for measuring metal parts. They use a principle when measuring on steel and eddy-current principles on aluminum. Measurement results are displayed on an easy-to-read liquid crystal display (LCD).

Typical tolerance is between ±1 and 3% Our basic electronic solution is called the PosiTest DFD. Two models are available, each capable of measuring up to 1000 microns (40 miles). The PosiTest DFT Ferrous model is recommended for steel substrates, while the PosiTest DFT COMBO model is ideal for measuring on all metal substrates.

Our most popular instrument for powder coaters is the PosiTest or 6000 u series of gages. They are ideal for the non-destructive measurement of powder coating thickness on metal substrates, an N series for non-steel substrates such as aluminium, and an FN series for measuring either application. Higher accuracy ferrous or non-ferrous Microprobes, with a range up to 625 microns (25 miles), are available for measuring in smaller, hard-to-reach areas.

Advanced models can store and print/download reading. As more customers purchase coating thickness gages to verify the quality of incoming products, it is becoming increasingly important that powder coaters have the ability to permanently record quality control data. Some powder coaters have even taken the next step of providing their customers with unsolicited reports showing the coating thickness reading as evidence of their process quality. ASTM Practice D7091 describes non-destructive measurement over metal substrates made with magnetic and eddy current coating thickness gages

Coatings on Non-metal substrates

Magnetic and eddy current instrumentals measure powder over metal. Non-metal applications such as coated plastic and wood require an ultrasonic pulse–echo technique. Ultrasonic testing works by sending an ultrasonic vibration into a coating using a probe (transducer) with the assistance of a gel (or drop water) temporarily applied to the surface.

This relatively new advancement allows industries to perform non-destructive quality control at an affordable price.

A benefit to this measurement technique is the possibility of measuring the individual layers in the multi-layer coating system. Our ultrasonic PosiTector 200 B std is ideal for measuring the thickness of powder coating applied to non-metal substrates. It has a range of 13 to 1000 µm (0.5 to 40 miles). ASTM D6132 describes this test.

While most powder coating specifications give cured thickness targets, it is possible to determine if the applied powder is within thickness specification before the finality of curing and cross-linking. There are good reasons for wanting an accurate prediction of cured thickness, especially on moving lines.

Depending upon the length of the oven, that is the number of parts being cured, as well as the time required for the curing process and for manual film thickness measurement after curing, there is a considerable delay before the operator can intervene in the application process to make any necessary changes.

If coating defects are discovered, a considerable number of coated parts have to be reworked in a repair loop or if reworking proves to be too expensive, they may even have to be scrapped. For some operations, these disadvantages are no longer acceptable for meeting the demands of modern finishing processes.

Measuring power in the pre-cured, pre-gelled state helps insure correct cured film thickness. It enables the application system to be set up and fine-tuned prior to curing. In turn, this will reduce the amount of scrap and over-spray. Accurate predictions help avoid stripping and re-coating which can cause problems with adhesion and coating integrity.

Test Procedures in Powder Coating Quality Control

ASTM D7378 describes three measurement methods for the thickness of applied, pre-cured coating powder to predict cured thickness.

A. Rigid metal notched (comb) gages.

B. Electronic coating gages with a special powder probe.

C. Non-contact ultrasonic instruments.

Procedure A uses the inexpensive DeFelsko Powder Comb which is much the same way as a wet film gauge. The comb is dragged through the uncured powder and powder height is considered to be a range value between the highest numbered tooth that made a mark and has powder clinging to it, and the next highest tooth that left no mark and has no powder clinging to it.

These gages are relatively inexpensive with an accuracy of ±5μm. Various Powder Comb models are available allowing measurements from 75 to 1250 microns (3 to 50 miles) on any substrate. They are only suitable as a guide since the cured film may be different after flow. Marks left by the gage may affect the characteristics of the cured film.

Procedure B uses a conventional magnetic or eddy current coating thickness gauge but with a specially designed powder probe to measure the thickness of the coating powder. Three micro pins, which are integrated into the probe, penetrate the coating powder down to the substrate. The probe is manually pressed down to the surface of the powder to effect a height measurement. This procedure is applicable to metal substrates only. Marks may be made in the powder that may not be covered when the powder flows in the curing process.

Procedure A and Procedure B result in only a height measurement of the uncured coating powder. But thickness specifications are most often stated in cured powder thickness. Since coating powders generally diminish in thickness during the curing process, these two procedures require a reduction factor to be established to predict cured film thickness for each particular coating powder.

This reduction factor is obtained by measuring the cured powder thickness at the same location where the uncured powder thickness measurement was taken. For best accuracy, measurements before and after curing should be taken for different thicknesses. A sample plot of measurement results is shown here. From this plot, a reduction factor can be determined and applied to all future dry coating powder thickness measurements to predict cured thickness.

Procedure C of ASTM D7378 describes a relatively new type of instrument the PosiTector PC Powder Checker. It is an ultrasonic device that can be used non-destructively on uncured powder to predict the thickness of the cured film. The Powder Checker is hand-held battery-powered and works right out of the box for most powders. It’s simplicity of operation and rugged design allow it to be used quickly and efficiently by line operators.

Non-contact coating thickness instruments have the advantage of being non-destructive. This means that after measurement, the measured components can be re-introduced into the process without being damaged.

Other Methods in Powder Coating Quality Control

Micrometers are sometimes used to check coating thickness. They have the advantage of measuring any coating/substrate combination but the disadvantage of requiring access to the bare substrate. Two measurements must be taken: one with the coating in place and the other without. The difference between the two readings, the height variation, is taken to be the coating thickness.

The destructive techniques are available. One is to cut the coated part in a cross-section and measure the thickness by viewing the cut microscopically. The other technique uses a scaled microscope to view a geometric incision through the cured coating. This method is used when non-destructive methods are not possible or as a way of confirming non-destructive results. ASTM Test Method D4138 describes destructive measurements over rigid substrates made with cross-sectioning instruments.

Units of measurement: The normal standard used in powder thickness measurement is the mil, where 1 mil is equal to a thousandth of inches (1/1000”). So if the manufacturer’s specified thickness is 2 to 5 mils, the final cured thickness of the powder should be between 0.002 and 0.005 of an inch. The metric unit of measurement is called the micron where 25.4 micron is equal to 1 mil.

Applications must apply the powder evenly and according to the product specification sheet. Background on Powder Coating Powder coating continues to be the fastest growing of all the finishing technologies. It is an attractive paint-like protective finish that is long-lasting and highly resistant to chips, scratches, and fading. It provides a seamless coating from a virtually unlimited selection of colors, textures, and finishes.

Powder coating is a cost-effective, one-step process that doesn’t require successive coats and long curing times. Powder particles used are a mixture of finely ground pigment and resin particles. Charged powder particles are transferred onto an electrically grounded surface. A variety of processes exist for powder application.

These applications range from electrostatic spraying for thinner coating (0.001” – 0.010”) to dipping in a fluidized bed for thicker coatings (0.007” – 0.040”) During the curing process, the powder is fused into a smooth coating. Dependent on the process, powders are either thermal cured (convection or infrared) or UV-cured. The powders used may be either thermoplastic (same chemical composition after reflowing) or thermosetting (chemically cross-linked with themselves or other reactive components)

UV-Curing in Powder Coating Quality Control

Unlike Thermal Cured powders, UV Curable powders separate the melting and film formation stages from the final curing stage. Short wave infrared and convection heat allows relative low temperatures to be used for the melting process. The result is lower temperature curing with improved flow.

The UV wavelength and time required for curing are based on the color and expected film thickness. Coating thickness can range from 20 to 100 microns (1 to 4 mils). The most significant challengers of UV-curing are the current cost of the powders required as well as the need a position the UV light to ensure 100% coverage.

Since UV-curing does not require high temperatures to cure, a significant reduction can be attained in required space, conveyors, and racking for the cooling process. Unlike thermal, UV provides instant curing which significantly increases throughput. Process savings are significant due to the decrease in energy and equipment required for heating.

UV powder is also easy to clean and recycle in energy providing a VOC-free process. Available markets are expanded as lower process temperatures allow heat-sensitive substrates (e.g. medium density fibreboard and plastics) to be powder coated. The cost of powder coating large mass parts (e.g. engine blocks) that act as heat sinks for thermal curing is also greatly reduced using UV curving.

Why Measure Thickness?

Coatings are designed to perform their intended function best when applied within a tight thickness range as specified by the manufacturer. This ensures optimum product performance. Many physical and appearance properties of the finished coating are affected by the film thickness. Film thickness can affect the color, gloss, surface profile, adhesion, flexibility impact resistance, and hardness of the coating.

The fit of pieces assembled after coating can be affected when the film thickness is not within tolerance. Therefore, the coating must be applied within certain minimum and maximum film thickness specifications to optimize its intended use. When insufficient powder coating is applied it does not provide adequate coverage and protection. For example, metals require a sufficient coating thickness for adequate protection from environmental effects such as corrosion (steel) or oxidation (aluminum). In addition, inadequate powder coating thickness may result in poor surface finish and undesirable appearance or color.

Powder Coating thickness may also affect the application’s impact resistance, flexibility, hardness, edge coverage, chip resistance, weathering, resistance to salt spray, and ability to retain gloss. Manufacturers provide a product specification sheet for powder coating measurements enabling the coater to adjust their coating process in process in accordance with the specifications. On medium density fibreboard (MDF) for example, powder coating thicknesses typically range between 1 and 8 mils (25 to 200 microns) or even higher for thermoplastic coating.

Usually, the finish is made more durable with thicker mil coverage. Factory specifications are often determined by just looking at it. There are other benefits to precisely measuring finish thickness whether to meet ISO, quality, and customer requirements for process control or to control costs. When companies fail to check and verify the coating quality of incoming material they waste money reworking products.

By checking their application equipment they ensure the coating is being applied in compliance with the manufacturer’s recommendations. Applying excessive film thickness risks the possibility of an incomplete cure and can drastically reduce overall efficiency. Too much powder coating may result in poor adhesion and tends to peel or chip from the substrate. Regular testing can reduce the number of internal reworks and customer returns due to finish defects.

Affordable

High-tech quality-control equipment can help companies maximize coating usage and boost their bottom lines. In the past, costly and complex color and thickness testing equipment primarily catered to larger companies with bigger budgets. However, in the past few years, quality-control testing equipment has decreased in price while advancing technologically, which makes purchasing the equipment more practical and affordable for smaller companies on tighter budgets.

Technology, advancements have been the key to the growing availability of thickness testing equipment. These improvements have helped manufacturers produce devices that are smaller and more portable, rugged and simple to use. Thickness gauges have also dropped in price because the materials used to produce them are more abundant. The same materials are mass-produced for use in cell phones, PDAs, and computers.

Measurement before the Curing for the Powder Coating Quality Control

Measurement methods described so far take place after the powder coating has cured. But if a coating has been improperly applied, correction after cure requires costly extra labor time, may lead to contamination of the film, and may introduce problems of adhesion and integrity of the coating system. Measuring film thickness before a cure can determine the need for immediate correction and adjustment by the applicator.

Measuring Dry Applied Powder

Again, depending on the solvent used it can be a health or fire hazard. Neither the oxide and scale removal can be achieved by mechanical scuffing, wire brushing, or for large areas, by abrasive blasting. Sand as an abrasive material has solvent vapor degreasing- using this technique the workpiece is suspended in the vapor of a chlorinated solvent such as trichloroethylene in a specially designed plant surface, which solubilizes the oil and grease which run off the parts with the liquid as it returns to the sump.

This is a much more efficient process because the solvent is continuously boiled up to replace the vapor that condenses.

On its own, this method will degrease effectively but any solid particles left on the surface may remain there after all the oil and grease have been removed. Improvements can be obtained by including a boiling liquor stage or by the use of ultrasonic agitation. In addition, special additives can be put into the chlorinated. Solvent to improve efficiency

Detergent: The workpiece can be dipped in or preferably sprayed with a solution of a suitable detergent in hot water and then rinsed and dried. This will effectively remove light contamination but will not deal with aged oil, grease, or heavy soils.

Emulsion cleaners: Emulsion cleaners are usually pre-emulsified kerosene/water emulsions, or kerosene-based concentrates which emulsify when added to water. Like the alkali cleaners, emulsions are most efficient when used in spray equipment but can be quite effective as immersion cleaners in many instances. Emulsions and cleaners normally operate at lower temperatures than the alkali type and in some cases can be used at ambient temperatures.

Alkali cleaners: Again the workpiece can either be dipped or sprayed with a hot aqueous solution of a suitable alkali mixture and then rinsed twice and dried. Spray application is more effective than dipping and it is cheaper as higher operating temperatures (70-90ºC ) and concentrations have to be used with the latter .spray application varies in time from 5-60 seconds whereas dip takes from 1-5 minutes. Immersion cleaners are available which separate the oil into a layer so that it can be floated off the cleaner surface over a suitable weir.

Alkali cleaners can effectively remove oil, grease, and soils and will cope readily with the heaviest contaminants.

There is a wide variety of alkali cleaners whose properties can be adjusted to give effective cleaning from any set of contaminates. These cleaners often

Oxide and scale removal: This can be achieved by mechanical scuffing, wire brushing or for large areas, abrasive blasting. Sand as an abrasive material has been banned in the UK as well as in many European countries.

The coarse expendable types of abrasive or re-usable metallic abrasive which took over from sand are now augmented by a whole range of ultra-fine abrasives, ranging from 600 mesh fused aluminous oxide by a whole range of ultra-fine abrasives, vegetable abrasives such as walnut shell and peach stones, through to tiny glass spheres less than 25µ in diameter with these extremely fine abrasives a complete surface uniformity can now be achieved.

Obviously using a very fine grit the rate of scale removal is rather slow, whereas a too coarse grit will give such a rough surface that the flow of the powder during stoving will be inhibited with consequent loss of gloss accompanied by an extremely rough surface profile. To provide some idea of the relative surface roughness on a steel surface that has been shot blasted the ‘peak to valley’ measurement would be about 100µ. with fused aluminous oxide (grade 180/220) it would be 3-5µ, while with glass beads it would be 1-1.5µ.

Oil and grease removal: This is usually the first step in the preparation of the metallic surface for coating there are numerous ways of carrying out this operation and some of the more common methods are briefly enumerated below.

Solvent wipe: Grease removal can be achieved by wiping the workpiece with a cloth soaked in a suitable solvent. This method will remove grease and solid matter fairly efficiently until first the cloth and then the solvent becomes dirty rags and the solvent will have to be replaced frequently. If only loose dust is the contaminate, tack-rags are often used. Although this method is quick and convenient for small-scale production, it suffers from high labor and material costs and, depending on the solvent selected, can be a fire or health hazard.

Solvent dip: With this method, the workpiece is immersed in a tank of solvent and after withdrawal, when the solvent has evaporated, all oil and greases should have been removed. This method remains effective until, like the solvent wipe, contamination has built up in the solvent dip tank and an equilibrium is reached whereby as much oil or grease is redeposited on the work as it takes off.

The only difference between the two methods

is that this oil is spread over the whole component. Better results can be obtained by having a number of tanks in line on a cascade principle, but this takes up considerable space and is expensive as solvent losses due to evaporation are high.

Iron phosphate coating is normally spray applied in a three or four stage operation. The work usually passes through two water rinse sections before drying. Zinc phosphate can be either spray or dip applied in a five-stage operation, i.e. alkali degrease, rinse, zinc phosphate, and two water rinses. Pre-treatment for zinc surface – A lightweight zinc phosphate coating is recommended. Generally, electro-deposited zinc coatings present no pretreatment problems but hot dipped galvanized coating can affect adhesion.

Increasing the degree of spangle decreases adhesion characteristics. Chromate conversion coating – The main conversion coating for aluminum and its alloys is a chromate coating that can be colorless or of the yellow chromium oxide or green chromic phosphate type. The coating weight recommended is 0.1 – 0.5g/m2 The five-stage process normally consists of an alkali degrease, rinse, and chromate conversion, followed by two rinses.

Again the chromate coating should be of low film weight for maximum adhesion. For high-quality applications, it is usually necessary to employ a final rinse with demineralized water. The conductivity of the final rinse bath is then monitored to ensure it cleanliness. No-rinse systems – one way of avoiding the need for this is to use a dry-in-place or no-rinse process. These are predominantly a form of chromate.

It is arguable whether they are true conversion coating or merely dried-on films with some reaction with the substrate but the advantages of needing no rinse are obvious. No-rinse system – One way of avoiding the need for this is to use a dry-place no-rinse process. These are predominantly a form of chromate. It is arguable whether they are true conversion coatings or merely dried-on films with some reaction with the substrate but the advantages of needling no rinse are obvious.

Heavy-metal-free pre-treatments – The increasingly strict environmental standards in the developed world mean that there is a move away from heavy metal containing pre-treatment, particularly chromate. Early chromate-free pretreatments had poor performance but more recently standards have improved with the first approval for use on architectural aluminum applications being awarded by the Qualicoat organization in 1996

Effluent disposal – Local authorities work to different standards in dealing with effluent discharge. However, they are all becoming more stringent and cautious as to what affluent they will accept. Include grain refining agents to ensure that phosphate coatings subsequently applied to steel surfaces have a fine-grained crystal structure.

In addition to the alkali, the mixtures contain detergents, emulsifiers, sequestering and chelating agents and occasionally water-softening additives. It should be noted that only under controlled conditions are alkali cleaners suitable for light alloys, zinc, galvanized metal or aluminum which are all attacked by alkali. Acid Cleaning – Acid pickling using either inhibited sulphuric or hydrochloric acid can completely remove rust and scale and can also condition the surface.

This method is usually confined to iron or steel surfaces. It is of paramount importance that when aqueous cleaning methods are employed great card be taken to ensure that subsequent water rinsing is of high standard to ensure that the dried and cleaned components are not contaminated with acid, alkali or emulsion. Also it a conversion coating system does not follow on in sequence the must be dried rapidly and effectively to prevent rusting of the surface.

Phosphating conversion coatings – the recognized pre-treatment for steel substrates just prior to application of powder is phosphating which can vary in coating weight. The greater the conversion coating weight the greater the degree of corrosion resistance achieved; the lower the coating weight the better the mechanical properties and corrosion resistance. High phosphate coating weights can give trouble with powder coating in that crystal fracture can occur when the coating is subjected to locally applied mechanical forces, e.g. bending or impact.

Due to the excellent adhesion of the powder coating to the phosphate coating, disbandment will usually occur at the phosphate/metal substrate interface rather than at the phosphate/powder coating interface. Phosphate coating is covered by BS3189/1959, class C for zinc phosphate, and class D for iron phosphate. A fine grain crystalline zinc phosphate is recommended at coating weights of 1- 2g/m2 and for iron phosphate at 0.3-1g/m2. The application can be spry or dip. Chromate passivation is not usually necessary.

Porous casting and ‘blast cleaned’ surface surfaces can give a considerable difficulty with ‘blowing’ of the powder coating due to entrapment of air. The profile of the metal and thickness of the coating must therefore be strictly controlled. Preheating for a few minutes sometimes overcomes this defect.

Substrate Pre-treatment prior to Coating

The main aims in the preparation of a metal surface prior to powder coating may be defined as follows:

- The complete removal of all foreign matter e.g. scale, grease, cutting, oil, soil, welding splatter etc.

- The conditioning of the surface so as to render it suitable for the coating that is to be applied.

- The pre-treatment should impart uniformity throughout all treated work piece surfaces, irrespective of the source of the metal or of the contaminants that might adhere.

As with other methods of organic finishing attention to the pre-treatment stage is essential in order to achieve the full potential of the powder coating. Surface pre-treatment may vary depending upon the specific end-use requirements of the finished products – from a single-step cleansing operation to a multi-stage sophisticated pre-treatment that deposits a conversion coating on the surface of the metal.

Application of coating of electrostatically charged particles to an earthed metal surface can only be achieved if the surface if free of any composition which has a high electrical resistance. The presence of any insulating film on the surface of the workpiece to be coated will limit or in some cases prevent powder being deposited.

Substrates – steel, aluminum, copper, zinc allows and galvanized steel are common metals on which powder is used. In a number of cases where normal service conditions apply, satisfactory properties can be obtained on thoroughly cleaned metal. Steel – for iron/steel surfaces maximum corrosion and salt spray resistance are given by a zinc phosphate conversion coating. Aluminum – for aluminum and its alloys, although the clean surfaces are easily coated and adhesion is excellent, performance can be upgraded using a proprietary chromate conversion coating.

Zinc allows – with all zinc-based substrates such as Zintec, Mazac and Galvanised Steel a suitable phosphate coating is recommended. Porous castings – and ‘blast cleaned’ surface – These surfaces can give considerable difficulty with ‘blowing’ of the powder coating due to entrapment of air. The profile of the metal and thickness of the coating must therefore be strictly controlled. Preheating for a few minutes sometimes overcomes this defect.

Generally, iron phosphate solutions can be passed to drain without treatment, zinc phosphate solutions usually have to be below a specified concentration lever which can normally be achieved by diluting in ordinary water. Some final rinse solutions contain chromate, which requires special treatment because of its toxic effects on marine life.