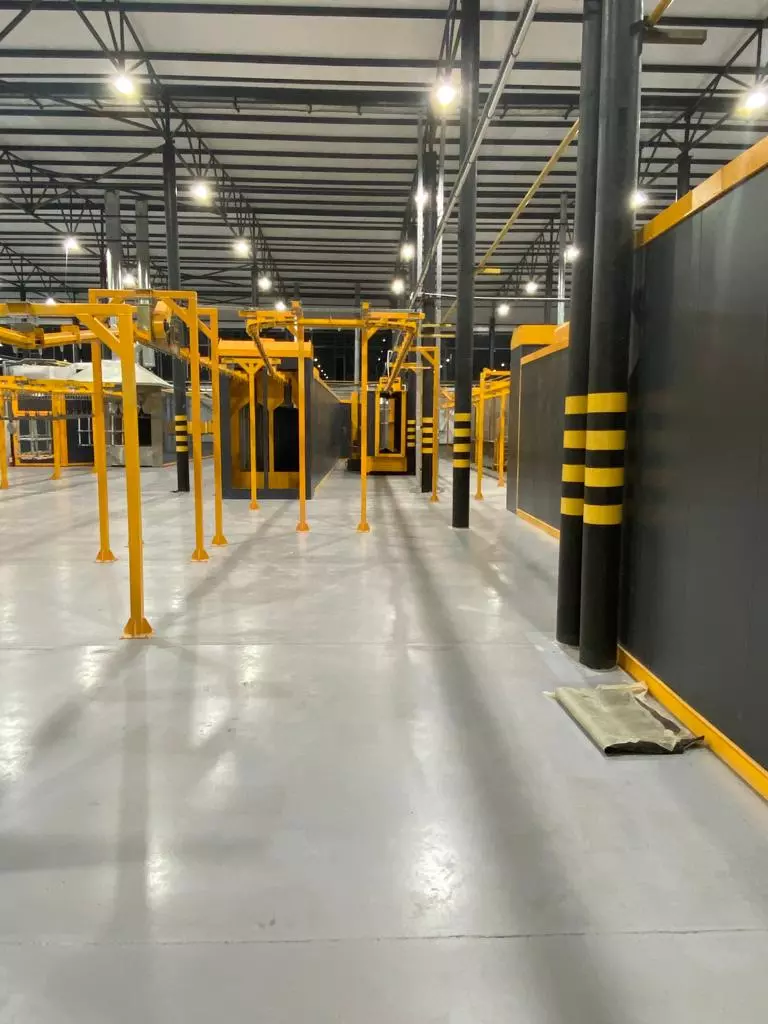

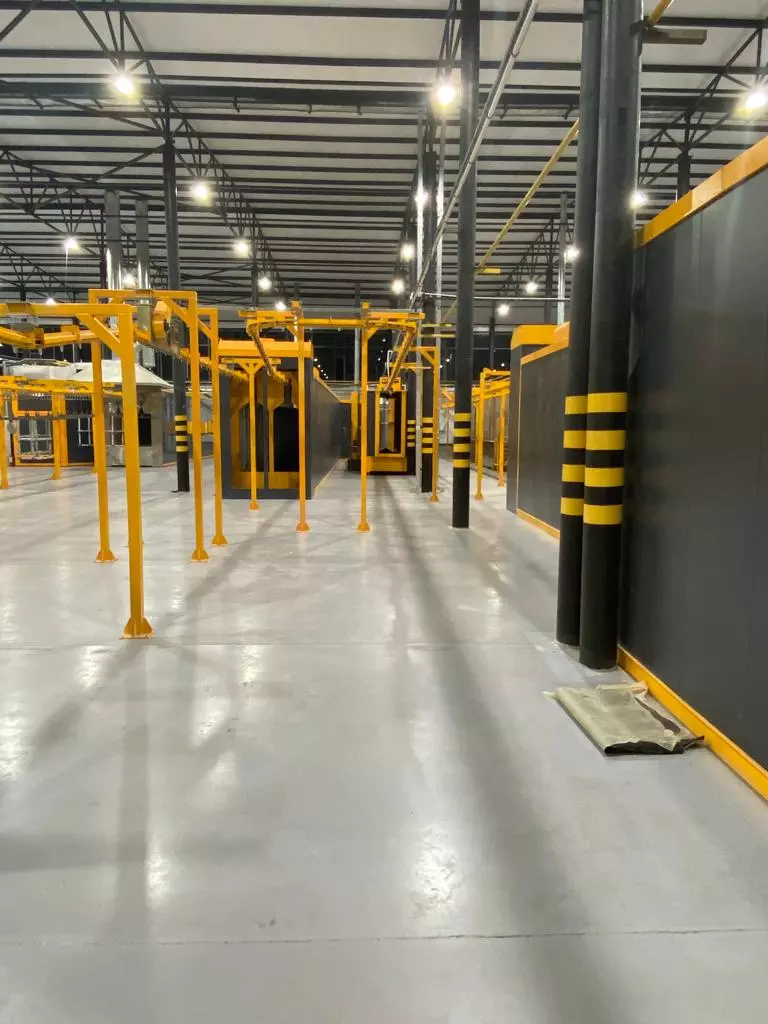

A small powder coating booth is the easiest solutions for powder coating applications when you don’t have many colors and you don’t need to change colors often. Our manual powder coating spray booths are designed and manufactured either from galvanized sheets or mild steel sheets which are then painted.

There is an inside space for the painter to hang his parts and paint with his powder coating gun, while filters suck and clean the air in the medium and blow off the paint gathered on the filters once in a while.

Manual powder coating booths can be made starting from 1 filter and 2,3,4,5,6 and 8 filters maximum. We use 32x60cm cellulose powder coating filters in our booths. There is an electrical board, to control the blow-off valves to clean the filters and lights inside for the operator to see and check the painting quality

Filtration is achieved by using cartridge filters in an open compartment. The filtered clean air (now devoid of powder particles) then passes through a sealed plenum chamber and via the centrifugal extraction fan back into the factory atmosphere. The system avoids any explosion risk that may be caused by passing powder-laden unfiltered air into a sealed chamber.

Sound Level Due to the level of airflow required the noise level determines that ear defenders are required.

Small Powder Coating Booth

Small powder coating booths are compact and versatile enclosures designed for applying powder coatings to smaller workpieces or for low-volume production. They offer a cost-effective solution for businesses that require powder coating capabilities without investing in large, industrial-scale booths.

Advantages of Small Powder Coating Booths

- Space Efficiency: Small booths occupy minimal space, making them suitable for smaller workshops or limited production areas.

- Cost-Effectiveness: The smaller size and simpler design of these booths translate into lower initial investment costs.

- Versatility: Small booths can accommodate a variety of workpiece sizes and shapes, catering to diverse production needs.

- Portability: Some smaller booths are designed to be portable, allowing for easy relocation and temporary setups.

- Energy Efficiency: Smaller booths require less energy to operate, reducing energy consumption and costs.

Components of Small Powder Coating Booths

- Enclosure: The enclosure provides a controlled environment for applying powder coating and preventing overspray contamination. It typically includes walls, a ceiling, a floor grate, and an exhaust system.

- Powder Coating Guns: Powder coating guns apply the powder onto the workpieces. Electrostatic guns are commonly used in small booths due to their efficient powder distribution.

- Powder Recovery System: A powder recovery system collects overspray powder, reducing waste and allowing for powder reuse. It may involve cyclones, filters, or a combination of both.

- Air Circulation System: The air circulation system ensures even distribution of powder and removal of overspray. It consists of fans, ducts, and plenums.

- Control System: The control system regulates the operation of the booth, including powder delivery, air circulation, and powder recovery. It may involve timers, sensors, and control panels.

Applications of Small Powder Coating Booths

- Small-Scale Production: Small booths are ideal for low-volume production of powder-coated parts.

- Prototyping and Testing: Small booths provide a convenient and cost-effective setup for prototyping and testing new powder coating applications.

- Customizing and Repairing: Small booths can be used for customizing or repairing smaller items, such as bicycle frames, motorcycle parts, or hardware components.

- Powder Coating Services: Small booths are suitable for businesses offering powder coating services to individual customers or small businesses.

- Educational and Training Purposes: Small booths can be used in educational settings or training centers to teach powder coating techniques.

Considerations When Choosing a Small Powder Coating Booth

- Workpiece Size and Volume: Select a booth that can accommodate the size and volume of your typical workpieces.

- Ventilation Requirements: Ensure the booth has adequate ventilation to handle the amount of powder being used and comply with local regulations.

- Filter Efficiency: Choose filters that are appropriate for the type of powder being used and provide the necessary level of filtration.

- Safety Features: Ensure the booth has safety features such as emergency shut-off switches, grounding connections, and proper lighting.

- Ease of Use: Consider the booth’s design and controls for ease of operation and maintenance.

Conclusion

Small powder coating booths offer a practical and cost-effective solution for smaller-scale powder coating applications. By selecting the appropriate booth, considering ventilation and safety requirements, and ensuring proper maintenance, businesses can achieve high-quality powder coating results while maximizing space efficiency and resource utilization.

Powder Coating Booth Design

The powder coating spray booth design in the EU countries is usually chosen as the open type. Here it is also possible to make powder coating over powder coating. This method is also called spraying over powder coating and is usually used for parts that need to have a longer service life.

The powder paint booth is designed according to the inner space and we have the following options for our powder paint booths:

- 2 Filter Booth inner dimensions in mm: 1200(W) x 1500(D) x 2250(H)

- 3 Filter Booth inner dimensions in mm: 1500(W) x 1500(D) x 2250(H)

- 4 Filter Booth inner dimensions in mm: 2000(W) x 1500(D) x 2250(H)

- 5 Filter Booth inner dimensions in mm: 3000(W) x 1500(D) x 2250(H)

- 6 Filter Booth inner dimensions in mm: 4000(W) x 1500(D) x 2250(H)

- 8 Filter Booth inner dimensions in mm: 5000(W) x 1500(D) x 2250(H)

- 10 Filter Booth inner dimensions in mm: 6000(W) x 1500(D)x 2250(H)

A small powder coating booth, often referred to as a small powder coating enclosure or mini powder coating booth, is a compact and enclosed workspace designed for applying powder coatings to small or medium-sized workpieces. These booths are commonly used in settings such as small manufacturing operations, custom coating shops, automotive garages, and hobbyist workshops. Here are the key features and considerations for a small powder coating booth:

- Enclosure Size: Small powder coating booths are designed to accommodate workpieces of various sizes, but they are generally smaller in scale compared to larger industrial booths. The booth’s dimensions can vary, but they are typically designed to fit within limited workshop or garage spaces.

- Powder Containment: Like larger booths, small powder coating booths are designed to contain overspray powder during the coating process. This containment prevents powder from escaping into the surrounding environment.

- Exhaust and Ventilation: Proper ventilation and exhaust systems are critical in small powder coating booths to remove excess powder and maintain a clean and safe working environment. Adequate airflow helps in controlling airborne particles and fumes.

- Powder Recovery: Some small booths may include a powder recovery system, such as a simple filter unit, to collect and reclaim overspray powder. This reduces material waste and lowers operating costs.

- Lighting: Adequate lighting is essential for operators to see and inspect the workpieces during the coating process. Good visibility ensures consistent and even powder application.

- Access Doors: Access doors or openings allow for the placement and retrieval of workpieces. These doors should be easy to open and close, ensuring efficient workflow.

- Powder Coating Gun: Small booths typically use manual powder coating guns for their versatility and ease of use. The choice of gun can vary depending on the specific application requirements.

- Control Panel: A control panel with basic controls for adjusting powder flow rate and fan speed may be included, allowing for some customization of the coating process.

- Workpiece Handling: Small booths may have racks, hooks, or hangers to hold and suspend workpieces during coating. The design should maximize space usage within the limited booth size.

- Safety Features: Safety features such as grounding mechanisms, emergency shut-off switches, and safety interlocks should be integrated into the booth to ensure operator safety.

- Compliance: Small powder coating booths should adhere to safety regulations and standards specific to the region and industry in which they are used.

Small powder coating booths are suitable for a range of applications, including coating automotive parts, motorcycle components, bicycles, small appliances, and various metal or plastic objects. They offer the advantage of space efficiency and are often more affordable than larger industrial booths. However, they are best suited for projects that do not require high production volumes or oversized workpieces.

Small Powder Coating Booth for Alloy Wheel Painting

A small powder coating booth for alloy wheel painting is an essential piece of equipment for any business that powder coats alloy wheels. A small powder coating booth is typically designed to accommodate one or two alloy wheels at a time. This makes it ideal for small businesses or businesses that only need to powder coat a small number of alloy wheels per day.

Benefits of Using a Small Powder Coating Booth for Alloy Wheel Painting

There are many benefits to using a small powder coating booth for alloy wheel painting, including:

- Affordability: Small powder coating booths are typically more affordable than larger booths.

- Portability: Small powder coating booths are typically portable, making them easy to move and install in different locations.

- Ease of use: Small powder coating booths are typically easy to use, even for beginners.

- Efficiency: Small powder coating booths can powder coat alloy wheels quickly and efficiently.

- High-quality finish: Small powder coating booths can produce a high-quality finish on alloy wheels.

Features of a Small Powder Coating Booth for Alloy Wheel Painting

A small powder coating booth for alloy wheel painting typically has the following features:

- Compact size: Small powder coating booths are typically designed to fit in small spaces.

- Powder coating spray gun: A powder coating spray gun is used to apply the powder coating to the alloy wheels.

- Powder coating recovery system: A powder coating recovery system collects the overspray powder and returns it to the powder coating hopper for reuse.

- Ventilation system: A ventilation system removes the powder coating dust from the booth.

- Lighting system: A lighting system provides adequate lighting for the powder coating process.

How to Choose a Small Powder Coating Booth for Alloy Wheel Painting

When choosing a small powder coating booth for alloy wheel painting, it is important to consider the following factors:

- The size of the alloy wheels you need to powder coat: Make sure to choose a booth that is large enough to accommodate the largest alloy wheels you need to coat.

- The type of powder coating you are using: Some types of powder coating require different booth conditions. Choose a booth that is compatible with the type of powder coating you are using.

- The production volume: If you need to powder coat a high volume of alloy wheels, you will need a booth that is fast enough to keep up with the demand. Choose a booth with a high capacity and fast curing times.

- The budget: Small powder coating booths can range in price from a few thousand dollars to tens of thousands of dollars. Choose a booth that fits your budget.

Operating and Maintaining a Small Powder Coating Booth for Alloy Wheel Painting

Once you have chosen a small powder coating booth for alloy wheel painting, it is important to learn how to operate and maintain it properly. This will help to ensure that the booth produces a high-quality finish and lasts for many years.

Here are some tips for operating and maintaining a small powder coating booth for alloy wheel painting:

- Clean the booth regularly: Powder coating dust can build up inside the booth over time, which can reduce the quality of the finish. Clean the booth regularly to remove any dust buildup.

- Inspect the booth regularly: Inspect the booth regularly for any signs of wear or damage. If you find any problems, have them repaired immediately.

- Calibrate the booth’s powder coating system regularly: The booth’s powder coating system should be calibrated regularly to ensure that the system is applying the powder coating correctly.

- Follow the manufacturer’s instructions: Be sure to follow the manufacturer’s instructions for operating and maintaining your small powder coating booth for alloy wheel painting.

Safety Precautions

Small powder coating booths for alloy wheel painting can be dangerous if not used properly. Here are some safety precautions to follow when using a small powder coating booth for alloy wheel painting:

- Wear personal protective equipment (PPE): Wear PPE, such as a respirator, gloves, and goggles, when using a small powder coating booth for alloy wheel painting. This will help to protect you from the powder coating dust and fumes.

- Ventilate the area: Make sure that the area where you are using the booth is well ventilated. This will help to remove the powder coating dust and fumes from the air.

- Keep the booth clean: Keep the booth clean to prevent powder coating dust from building up.

- Follow the manufacturer’s instructions: Be sure to follow the manufacturer’s instructions for safely operating and maintaining your small powder coating booth for alloy wheel painting.

Conclusion

A small powder coating booth for alloy wheel painting is an essential piece of equipment for any business that powder coats alloy wheels. By choosing the right booth and operating and maintaining it properly, you can ensure that

Small Powder Coating Booth

A small powder coating booth is a controlled environment where the process of powder coating is carried out. Powder coating is a type of coating that is applied as a dry powder and then cured to form a hard finish. The booth provides a contained space for the application of the powder, ensuring a clean and efficient process. Here are some key elements and considerations for a small powder coating booth:

- Enclosure:

- The booth should be enclosed to contain the powder overspray and prevent it from spreading to the surrounding area.

- Walls and ceiling materials should be easy to clean to maintain a clean working environment.

- Ventilation:

- Proper ventilation is crucial to remove airborne powder particles and ensure a safe working environment.

- An exhaust system with adequate airflow is necessary to capture and filter the powder particles.

- Filtration System:

- Install a high-quality filtration system to capture and filter out the powder particles from the air. This helps maintain air quality and prevent environmental contamination.

- Filters may include primary and secondary filters, and they should be regularly checked and replaced.

- Lighting:

- Adequate lighting is essential for accurate application of the powder coating.

- Ensure that the lighting is positioned to minimize shadows and provide uniform illumination.

- Grounding and Static Control:

- Implement measures to control static electricity, as it can interfere with the powder coating process.

- Proper grounding of the booth, equipment, and personnel is critical to prevent electrostatic discharge.

- Size and Layout:

- Design the booth to accommodate the size and shape of the parts you will be coating.

- Consider the layout for efficient workflow and ease of movement.

- Powder Application Equipment:

- Install a powder coating gun and related equipment suitable for the scale of your operations.

- Ensure that the equipment is properly maintained for consistent and quality coatings.

- Curing Oven:

- Depending on the type of powder used, a curing oven may be necessary to bake the powder-coated parts and achieve the desired finish.

- The oven should be appropriately sized for the parts being coated.

- Safety Measures:

- Implement safety features such as emergency stop buttons, fire suppression systems, and proper personal protective equipment for operators.

- Compliance with Regulations:

- Ensure that the booth complies with local environmental and safety regulations related to powder coating operations.

When setting up a small powder coating booth, it’s important to carefully plan and design the space to meet your specific requirements and comply with industry standards and regulations. Additionally, training operators on proper powder coating techniques and safety procedures is essential for successful and safe operations.

Parts of the Small Powder Coating Booth

Certainly, when referring to the components or parts of a small powder coating booth, here are the key elements typically found in such a setup:

- Booth Enclosure:

- Walls, ceiling, and floor materials designed to contain overspray and maintain a clean environment.

- Ventilation System:

- Exhaust fan(s) to facilitate airflow and remove airborne powder particles.

- Ductwork to direct air and contaminants outside the booth.

- Air intake system to maintain a balanced airflow.

- Filtration System:

- Primary and secondary filters to capture and remove powder particles from the air.

- Filter housing and frames.

- Lighting:

- Light fixtures strategically placed to illuminate the work area effectively.

- Grounding and Static Control:

- Grounding wires and rods to prevent static buildup.

- Anti-static flooring or grounding straps for personnel.

- Powder Application Equipment:

- Powder coating gun: The device used to apply the powder to the workpiece.

- Control unit for adjusting voltage, current, and airflow.

- Powder delivery system, including hoses and nozzles.

- Recovery System:

- Booth-mounted or external powder recovery system to collect oversprayed powder for reuse.

- Curing Oven:

- Oven or heating system for curing the powder-coated parts.

- Temperature control system.

- Safety Features:

- Emergency stop buttons or switches.

- Fire suppression system.

- Proper signage indicating safety protocols.

- Control Panel:

- Central control panel for managing various aspects of the powder coating process, such as fan speed, temperature, and safety features.

- Personnel Protection:

- Personal protective equipment (PPE) for operators, including gloves, masks, and aprons.

- Access Doors:

- Doors for entry and exit, designed to prevent powder leakage.

- Powder Storage Area:

- If applicable, a designated area for storing different types and colors of powder.

- Compliance Equipment:

- Devices for monitoring and ensuring compliance with environmental and safety regulations.

- Cleanout System:

- System for cleaning and maintaining the booth, such as vacuum systems for removing accumulated powder.

- Workpiece Handling Equipment:

- Racks, hooks, or other fixtures for holding and moving the workpieces through the coating process.

When setting up a small powder coating booth, it’s important to ensure that each component is appropriately sized and installed to facilitate an efficient and safe powder coating process. Additionally, regular maintenance and adherence to safety protocols are essential for optimal performance and operator well-being.

Booth Enclosure

The booth enclosure in a powder coating setup serves as the physical structure that contains the powder coating process, preventing overspray and maintaining a controlled environment. Here are key aspects of the booth enclosure:

- Material:

- Walls, ceiling, and floor of the booth are typically constructed using materials that are easy to clean and resist the build-up of powder residue. Common materials include galvanized steel, stainless steel, or other non-porous surfaces.

- Construction:

- The booth is constructed to be sturdy and durable, providing a secure space for the powder coating process.

- Modular construction is common, allowing for flexibility in booth size and configuration.

- Seals and Gaskets:

- Seals and gaskets are used at joints and openings to ensure that the booth is airtight. This prevents the escape of powder particles and maintains proper airflow within the booth.

- Access Doors:

- The booth typically includes access doors for personnel to enter and exit. These doors should have proper sealing mechanisms to prevent powder leakage.

- Windows and Viewing Panels:

- Some booths have windows or viewing panels to allow operators to monitor the coating process without opening the doors, minimizing the risk of powder escaping.

- Lighting:

- Adequate lighting is crucial for operators to see and inspect the workpieces. Light fixtures are strategically placed within the booth to provide uniform illumination.

- Exhaust Openings:

- Exhaust openings are strategically located to facilitate the capture and removal of airborne powder particles. These openings are connected to the ventilation system.

- Hanger System:

- If applicable, a system for hanging or supporting the workpieces during the coating process. This may include hooks, racks, or other fixtures.

- Grounding Points:

- Grounding points are installed to dissipate static electricity, reducing the risk of electrostatic discharge during the coating process.

- Cleaning Accessibility:

- Design features that facilitate easy cleaning of the booth, including smooth surfaces and removable panels for access to all areas.

- Fire Safety Measures:

- The booth may be equipped with fire safety features such as fire-resistant materials and fire suppression systems to ensure operator safety.

- Compliance with Regulations:

- Booth construction and materials should comply with local regulations and safety standards related to powder coating operations.

When designing and setting up a powder coating booth enclosure, it’s crucial to consider the size and type of workpieces to be coated, the volume of coating operations, and environmental and safety regulations. Regular maintenance and cleaning of the booth are essential to ensure consistent and high-quality powder coating results.

Ventilation System

The ventilation system in a powder coating booth is a critical component designed to control airflow, remove airborne powder particles, and maintain a safe and efficient working environment. Here are the key aspects of a ventilation system in a powder coating booth:

- Exhaust Fan(s):

- Powerful exhaust fans are installed to create a controlled airflow within the booth.

- The fans are strategically positioned to capture overspray and direct it towards the filtration system.

- Airflow Design:

- The ventilation system is designed to ensure a consistent and controlled airflow pattern throughout the booth.

- The goal is to prevent the escape of powder particles and direct them toward the exhaust system.

- Ductwork:

- Ducts are used to transport the air from the booth to the exterior or to a filtration system.

- Properly designed ductwork ensures efficient and effective removal of contaminants.

- Air Intake System:

- An intake system is incorporated to balance the airflow within the booth.

- It helps prevent negative pressure, which can affect the performance of the exhaust system.

- Balancing Airflow:

- The ventilation system is designed to balance the airflow to avoid turbulence and ensure consistent coating application.

- Variable Airflow Control:

- Some systems may have variable speed controls to adjust the airflow based on the specific coating requirements and workpiece sizes.

- Air Velocity Control:

- Control mechanisms may be in place to adjust the speed and direction of the airflow, allowing for optimization based on the coating process.

- Exhaust Openings:

- Exhaust openings or outlets are strategically positioned to capture overspray and direct it out of the booth.

- These openings are connected to the ductwork leading to the exhaust fan(s).

- Air Filters:

- Air filters are part of the ventilation system and are designed to capture and remove powder particles from the air.

- Primary and secondary filters may be used, and they should be regularly checked and replaced to maintain efficiency.

- Positive Pressure Zones:

- In some systems, positive pressure zones may be created to prevent outside air, contaminants, or ambient humidity from entering the booth.

- Environmentally Controlled Systems:

- Some advanced systems may include features to control temperature and humidity within the booth for optimal coating conditions.

- Compliance with Regulations:

- The ventilation system design should comply with local environmental and safety regulations governing powder coating operations.

Properly designed and maintained ventilation systems are crucial for the safety of operators, the quality of powder coating applications, and compliance with environmental regulations. Regular inspections, cleaning, and filter replacements are essential for the continued effectiveness of the ventilation system.

Filtration System

The filtration system in a powder coating booth plays a crucial role in capturing and removing powder particles from the air, ensuring a clean and safe working environment. Here are the key components and considerations for a filtration system in a powder coating booth:

- Primary Filters:

- Primary filters are the first line of defense and capture larger particles of overspray.

- They prevent these particles from reaching the more sensitive secondary filters, extending the life of the entire filtration system.

- Secondary Filters:

- Secondary filters are designed to capture finer particles that may pass through the primary filters.

- These filters provide higher efficiency in removing smaller particles from the air.

- Filter Housing and Frames:

- The filtration system includes housings and frames to securely hold the filters in place.

- Well-designed frames ensure a proper seal to prevent air bypass and maximize filtration efficiency.

- Filter Media:

- Filters are made of media that is specifically designed to capture and retain powder particles.

- Common filter media includes polyester, fiberglass, or other materials with high particle retention capabilities.

- Filter Replacement Indicators:

- Some systems are equipped with indicators to signal when filters need replacement.

- Regularly replacing filters is essential for maintaining optimal airflow and filtration efficiency.

- Accessibility for Maintenance:

- The filtration system should be designed for easy access to facilitate regular maintenance tasks such as filter replacement and cleaning.

- Air-to-Cloth Ratio:

- The air-to-cloth ratio is a key consideration in filter design and refers to the volume of air that can be filtered per unit of filter surface area.

- Properly balancing this ratio is crucial for efficient filtration.

- Filter Efficiency Rating:

- Filters are assigned an efficiency rating based on their ability to capture particles of a certain size.

- High-efficiency filters are important for maintaining air quality and complying with environmental regulations.

- Filter Type:

- Depending on the specific requirements and regulations, different types of filters may be used, such as bag filters, cartridge filters, or panel filters.

- Environmental Compliance:

- The filtration system must comply with local environmental regulations regarding the control of airborne contaminants generated during powder coating.

- Filter Disposal:

- Proper disposal methods for used filters must be followed to adhere to environmental guidelines.

- Filter Cleaning or Replacement Schedule:

- Establishing a regular schedule for filter maintenance, cleaning, or replacement is essential to ensure consistent performance.

- Pressure Drop Monitoring:

- Monitoring the pressure drop across the filters helps identify when they are becoming clogged and need replacement.

Regular inspection and maintenance of the filtration system are critical to the overall performance of the powder coating booth. It not only ensures a clean working environment but also contributes to the longevity and efficiency of the entire powder coating system.

Grounding and Static Control

Grounding and static control are crucial aspects of a powder coating booth to prevent the buildup of static electricity, which can interfere with the coating process and pose safety risks. Here are the key components and considerations for grounding and static control in a powder coating booth:

- Grounding Wires and Rods:

- Grounding wires are strategically installed to create a path for the dissipation of static electricity.

- Grounding rods may be driven into the ground outside the booth to provide a secure grounding connection.

- Grounding Points:

- Various components within the booth, such as the workpiece hangers, powder coating gun, and booth structure, should be equipped with grounding points.

- These points ensure that static charges are safely and efficiently grounded.

- Grounding Straps for Personnel:

- Operators and personnel working in the booth may use grounding straps or wrist straps to ensure that they are grounded and prevent the buildup of static charges on their bodies.

- Anti-Static Flooring:

- The booth floor may be constructed with anti-static or conductive flooring materials.

- Anti-static flooring helps dissipate static charges and provides a safe working environment for personnel.

- Ionization Systems:

- Ionization systems release ions into the air, neutralizing static charges on surfaces.

- These systems can be installed at various points in the booth to minimize the risk of electrostatic discharge.

- Conductive Equipment:

- Powder coating guns, workpiece hangers, and other equipment used in the booth may be designed with conductive materials to aid in grounding.

- Proper Workpiece Grounding:

- Ensuring that workpieces are properly grounded before the coating process begins is essential to prevent the attraction of airborne powder particles due to static charges.

- Static Control Devices:

- Devices such as static control bars or brushes may be installed along the conveyor system or in areas where workpieces move to reduce static charges.

- Humidity Control:

- Maintaining a controlled level of humidity in the booth can help reduce the buildup of static electricity.

- Humidity acts as a natural conductor and can enhance the effectiveness of static control measures.

- Operator Training:

- Proper training for operators on the importance of grounding and static control measures is essential for maintaining a safe working environment.

- Monitoring Systems:

- Implementing monitoring systems to regularly check the effectiveness of grounding and static control measures.

- Alarms or indicators may be included to alert operators if static electricity levels become a concern.

- Compliance with Safety Standards:

- Ensuring that the grounding and static control measures comply with relevant safety standards and regulations.

Proper grounding and static control measures are essential to prevent electrostatic discharge, which can negatively impact the quality of powder coating applications and pose safety risks to both personnel and equipment. Regular checks and maintenance of these measures are critical for their ongoing effectiveness.

Powder Application Equipment

Powder application equipment is a critical component of a powder coating system, responsible for applying the dry powder to the surface of the workpieces. The key element in this equipment is the powder coating gun. Here are the primary components and considerations for powder application equipment:

- Powder Coating Gun:

- The powder coating gun is the primary tool used to apply the dry powder to the workpiece.

- It features a nozzle through which the powder is electrostatically charged and sprayed onto the grounded workpiece.

- Control Unit:

- The control unit is responsible for adjusting and regulating various parameters of the powder coating process.

- It typically includes controls for voltage, current, and airflow to optimize the powder coating application.

- Powder Delivery System:

- The powder delivery system consists of hoses and tubes that transport the dry powder from the powder container to the powder coating gun.

- Properly designed delivery systems ensure a consistent and controlled flow of powder.

- Fluidizing Hopper or Powder Container:

- The powder is stored in a fluidizing hopper or a powder container equipped with a fluidizing system.

- The fluidizing system ensures that the powder remains in a suspended, fluid-like state for consistent feeding to the powder gun.

- Powder Sieve:

- A powder sieve is used to remove any clumps or impurities from the powder before it enters the powder gun.

- This ensures a smooth and even powder flow.

- Nozzles and Electrodes:

- Nozzles are a crucial part of the powder gun, determining the spray pattern and particle size.

- Electrodes within the gun charge the powder particles, enabling them to adhere to the grounded workpiece.

- Powder Cups or Containers:

- Some powder coating guns come with small powder cups or containers for easy color changes or testing.

- Gun Movers and Automation:

- In automated powder coating systems, gun movers or robots may be used to precisely control the movement of the powder coating gun for consistent coverage.

- Gun Cleaning Systems:

- Systems for purging and cleaning the powder coating gun, preventing cross-contamination of colors and ensuring the longevity of the equipment.

- Voltage Multipliers:

- Some powder coating guns feature voltage multipliers to generate higher electrostatic charges, improving powder transfer efficiency.

- Powder Recirculation Systems:

- In some setups, powder recirculation systems may be employed to reclaim and reuse excess powder that does not adhere to the workpiece.

- Compliance with Coating Requirements:

- The powder coating equipment should be selected based on the specific requirements of the coating process, including the type of powder used and the characteristics of the workpieces.

- Grounding Devices:

- The powder coating gun and associated equipment should have proper grounding devices to prevent electrostatic discharge.

- Operator Training:

- Proper training of operators on the correct use, maintenance, and troubleshooting of the powder application equipment is crucial for optimal performance.

When choosing powder application equipment, it’s essential to consider factors such as the type of powder, desired finish, production volume, and the characteristics of the workpieces. Regular maintenance and cleaning of the equipment are also necessary to ensure consistent and high-quality powder coating applications.

Recovery System

The recovery system in a powder coating booth is responsible for capturing and reclaiming excess powder particles that do not adhere to the workpieces during the coating process. This system helps minimize waste, reduce environmental impact, and optimize the use of powder materials. Here are the key components and considerations for a powder recovery system:

- Powder Recovery Booth or Module:

- A designated area within the powder coating booth or a separate module where the recovery process takes place.

- The booth or module is designed to contain the overspray and facilitate efficient powder recovery.

- Collector Modules or Filters:

- Collector modules or filters are positioned within the recovery system to capture oversprayed powder particles.

- These filters are designed to allow the powder to adhere while allowing clean air to pass through.

- Reclaiming Hopper or Cyclone Separator:

- The collected powder is directed to a reclaiming hopper or a cyclone separator where separation of the powder from the air occurs.

- The hopper or cyclone uses gravity or centrifugal force to separate the powder from the airflow.

- Recovery Fan:

- A dedicated recovery fan assists in creating the necessary airflow to transport the oversprayed powder from the booth to the recovery system.

- The fan aids in moving the powder through the collection process.

- Powder Recovery Pump:

- In some systems, a powder recovery pump may be employed to assist in transporting the collected powder to the reclaiming hopper or cyclone.

- Fluidizing System:

- A fluidizing system within the reclaiming hopper ensures that the collected powder remains in a fluid-like state for ease of transport and application.

- Powder Storage System:

- The recovered powder is directed to a storage system, which may include bins or containers.

- Properly designed storage systems allow for easy retrieval and reuse of the reclaimed powder.

- Sieves or Filters for Reclaimed Powder:

- Sieves or filters may be used to further refine the reclaimed powder, removing any impurities or larger particles before it is reused.

- Powder Pumps and Feeders:

- Powder pumps and feeders assist in transporting the reclaimed powder from the storage system to the powder application equipment.

- These components ensure a consistent and controlled flow of powder for subsequent coating processes.

- Monitoring and Control Systems:

- Monitoring systems are often integrated to track the performance of the recovery system.

- Control systems may adjust parameters such as fan speed or reclaiming hopper operation for optimal efficiency.

- Compliance with Environmental Regulations:

- The recovery system should comply with local environmental regulations related to the handling and reuse of powder materials.

- Regular Maintenance:

- Regular cleaning and maintenance of the recovery system components are crucial for its efficient operation and longevity.

Implementing an effective recovery system is essential for reducing powder waste, minimizing costs, and promoting sustainable powder coating practices. Regular maintenance and monitoring ensure that the system operates optimally and contributes to overall efficiency in the powder coating process.

Curing Oven

A curing oven is an essential component in the powder coating process, responsible for baking or curing the applied powder coating on the workpieces. The curing process transforms the powder into a durable and protective finish. Here are the key components and considerations for a curing oven in a powder coating system:

- Oven Chamber:

- The oven chamber is the enclosed space where the curing process takes place.

- It is constructed with materials that can withstand the curing temperatures and maintain a consistent temperature throughout the chamber.

- Heating Elements:

- Electric, gas, or infrared heating elements are used to provide the necessary heat for curing the powder coating.

- The type of heating elements depends on the specific requirements of the coating process.

- Temperature Control System:

- A temperature control system regulates the oven temperature to achieve and maintain the desired curing temperature.

- Precise temperature control is crucial for achieving a quality finish and avoiding over-curing or under-curing.

- Conveyor System:

- In continuous powder coating lines, a conveyor system is often integrated to move workpieces through the curing oven.

- The conveyor system ensures a consistent and controlled dwell time within the oven.

- Air Circulation System:

- Fans or blowers are used to circulate heated air within the oven chamber.

- Proper air circulation ensures uniform heat distribution and consistent curing across all surfaces of the workpieces.

- Insulation:

- The oven is insulated to minimize heat loss and maintain a stable internal temperature.

- Insulation materials are chosen to withstand high temperatures and provide energy efficiency.

- Exhaust System:

- An exhaust system may be integrated to remove any fumes or by-products generated during the curing process.

- Proper ventilation helps maintain a safe working environment.

- Cooling Zone:

- Some curing ovens include a cooling zone where workpieces gradually cool down after the curing process.

- Controlled cooling helps prevent damage to the cured coating and ensures a durable finish.

- Timer and Dwell Time Control:

- A timer system allows operators to set and control the dwell time, ensuring that workpieces remain in the oven for the required duration for complete curing.

- Monitoring and Safety Systems:

- Monitoring systems may be incorporated to track and display temperature, conveyor speed, and other critical parameters.

- Safety features such as emergency stop buttons and temperature alarms enhance the overall safety of the curing process.

- Compliance with Regulations:

- The curing oven design and operation should comply with local safety and environmental regulations associated with powder coating operations.

- Accessibility for Maintenance:

- Design features that facilitate easy access for maintenance tasks, such as cleaning or replacing heating elements and inspecting insulation.

- Heat Recovery Systems:

- In some cases, heat recovery systems may be implemented to capture and reuse excess heat, improving overall energy efficiency.

Properly designed and maintained curing ovens are crucial for achieving high-quality powder coating finishes. They play a significant role in ensuring the durability, adhesion, and appearance of the cured powder coating on the workpieces. Regular maintenance and adherence to safety protocols contribute to the longevity and effectiveness of the curing oven.

Powder coating

Powder coating is a widely used finishing process in manufacturing, characterized by its ability to produce a high-quality, durable finish. The process involves the application of dry powder to a surface, which is then cured under heat to form a solid, protective coating. This process is favored in many industries due to its efficiency and environmental benefits compared to traditional liquid paint. Essential to the powder coating process are various pieces of equipment, including the Powder Coating Equipment, Powder Coating Booth, Powder Coating Spray Booth, Small Powder Coating Booth, and Powder Paint Booth with Filters.

Powder Coating Equipment Overview

Powder Coating Equipment encompasses a wide range of tools and machinery designed to facilitate the powder coating process. These include spray guns, booths, ovens, and automated systems. Each component plays a crucial role in ensuring the quality and efficiency of the coating process. For instance, Automatic Powder Coating Equipment is often used in large-scale operations where precision and consistency are paramount.

Powder Coating Booths

A Powder Coating Booth is a controlled environment where powder is applied to the substrate. These booths are designed to contain overspray, minimize contamination, and ensure even coating application. There are various types of booths, including the Small Powder Coating Booth, which is ideal for limited-space operations or for coating smaller parts. For larger operations, a Powder Coating Spray Booth is typically used, which allows for greater flexibility and efficiency.

Small Powder Coating Booths and Applications

Small Powder Coating Booths are specifically designed for operations that require a compact setup. These booths are particularly useful in small workshops or for businesses that specialize in coating small parts, such as Alloy Wheel Powder Coating. A Small Powder Coating Booth is typically paired with a Small Powder Coating Oven or a combined Small Powder Coating Booth and Oven to streamline the coating and curing processes.

Automated Powder Coating Systems

For businesses that require high throughput and consistent quality, an Automated Powder Coating System is often the best choice. These systems integrate various components of the powder coating process, including automated spray guns, conveyor systems, and curing ovens. By automating these processes, manufacturers can achieve a higher level of efficiency and reduce the potential for human error.

Ovens in Powder Coating

Curing ovens are an essential part of the powder coating process. They provide the heat necessary to cure the powder and form a durable coating. There are different types of ovens, including Gas Powder Coating Oven, Diesel Powder Coating Oven, and Portable Powder Coating Oven. Each type of oven offers distinct advantages depending on the application. For instance, a Gas Powder Coating Oven is known for its energy efficiency and consistent temperature control, while a Diesel Powder Coating Oven is favored in environments where gas supply is limited or where diesel is more readily available.

Portable Powder Coating Ovens

Portable Powder Coating Ovens are a versatile solution for businesses that require mobility in their operations. These ovens can be moved easily to different locations, making them ideal for on-site jobs or businesses with limited space. Despite their portability, these ovens are capable of delivering high-quality curing results comparable to their stationary counterparts.

Specialized Coating Applications: Alloy Wheel Powder Coating

Alloy Wheel Powder Coating is a specialized application of powder coating that involves applying a durable finish to alloy wheels. This process not only enhances the appearance of the wheels but also provides protection against corrosion and wear. The equipment used for this application typically includes a Small Powder Coating Booth and Oven to accommodate the size of the wheels and ensure a thorough and even coating.

Small Powder Coating Booths and Ovens

Combining a Small Powder Coating Booth with a Small Powder Coating Oven is an effective setup for operations that deal with smaller parts. This combination allows for a seamless transition from coating to curing, ensuring that the coated parts are handled efficiently and without the risk of contamination or damage.

Advantages of Automatic Powder Coating Equipment

The use of Automatic Powder Coating Equipment provides several advantages, particularly in high-volume production settings. Automation ensures that each part is coated with precision and consistency, reducing waste and increasing productivity. Additionally, automated systems can be programmed to handle various part sizes and shapes, making them a versatile option for manufacturers.

Conclusion

In conclusion, powder coating is an essential process in many industries, offering a durable and high-quality finish that is both environmentally friendly and cost-effective. The equipment used in this process, including Powder Coating Equipment, Powder Coating Booths, Automated Powder Coating Systems, and various types of ovens, plays a crucial role in achieving the desired results. Whether you are operating a small workshop or a large-scale manufacturing facility, the right combination of equipment can significantly enhance your production capabilities and product quality.

Powder Coating Equipment

Powder Coating Equipment encompasses a variety of tools and machines that are essential for applying powder coatings to various substrates. This equipment typically includes:

- Powder Spray Guns: These are devices used to apply the powder evenly onto the surface of the object. They can be manual or automated, with the latter offering greater consistency and efficiency.

- Powder Coating Booths: These are enclosed areas where the powder is applied, designed to contain overspray and prevent contamination.

- Curing Ovens: After the powder is applied, the coated object is placed in an oven to cure, which involves melting the powder so it flows together to form a smooth, solid coating.

- Control Systems: These systems manage the application parameters, such as temperature, spray rate, and curing time, ensuring the process is consistent and repeatable.

Powder Coating Booth

A Powder Coating Booth is a specialized enclosure designed to contain the powder application process. The booth serves several key functions:

- Overspray Containment: The booth ensures that any powder that doesn’t adhere to the substrate is captured and can often be recycled, reducing waste.

- Controlled Environment: By isolating the coating process, the booth minimizes contamination from dust and other particles, which could affect the finish quality.

- Airflow Management: Proper airflow within the booth ensures that the powder particles are evenly distributed and that overspray is efficiently collected.

There are various types of booths, such as open-faced booths, enclosed booths, and walk-in booths, each designed for different scales and types of operations.

Small Powder Coating Booth

A Small Powder Coating Booth is designed for operations that do not require large-scale equipment. These booths are ideal for small parts, prototypes, or businesses with limited space. Features of small booths include:

- Compact Design: These booths are smaller in size, making them suitable for tight spaces or mobile operations.

- Cost-Effective: They are often less expensive than larger booths, making them an economical choice for small businesses or hobbyists.

- Efficiency: Despite their size, small powder coating booths are equipped to handle a variety of coating tasks with high precision.

Powder Coating Spray Booth

A Powder Coating Spray Booth is a type of booth specifically designed to accommodate the spraying process of powder application. This type of booth is equipped with:

- Advanced Filtration Systems: These systems filter the air to remove any particles, ensuring a clean environment for the coating process.

- Adjustable Airflow: Airflow can be adjusted to optimize the application and ensure even coating on all surfaces.

- Ergonomic Design: Spray booths are often designed to maximize operator comfort and efficiency, with easy access to all areas of the parts being coated.

Powder Paint Booth with Filters

A Powder Paint Booth with Filters is equipped with specialized filtration systems to capture overspray and maintain air quality within the booth. These filters play a critical role in:

- Ensuring Air Quality: Filters remove airborne powder particles, preventing them from escaping the booth and affecting the surrounding environment.

- Reducing Waste: Captured powder can often be recycled, reducing material costs and waste.

- Maintaining Finish Quality: Clean air within the booth ensures that the powder coating adheres smoothly and evenly, free from contaminants.

Automated Powder Coating System

An Automated Powder Coating System integrates various stages of the powder coating process into a seamless, automated workflow. Key features of these systems include:

- Conveyor Systems: Parts are transported automatically through the different stages of coating and curing, increasing efficiency and throughput.

- Automated Spray Guns: These guns apply powder coatings consistently across parts, reducing the potential for human error and ensuring uniformity.

- Real-Time Monitoring: Sensors and control systems monitor the process in real-time, adjusting parameters as needed to maintain optimal coating conditions.

- Scalability: Automated systems can be scaled to meet the demands of different production volumes, from small batches to large-scale manufacturing.

Gas Powder Coating Oven

A Gas Powder Coating Oven is used to cure powder-coated parts by heating them to the required temperature. These ovens are powered by natural gas and offer several advantages:

- Energy Efficiency: Gas ovens are generally more energy-efficient than electric ovens, making them a cost-effective option for large-scale operations.

- Consistent Heating: They provide uniform temperature distribution, which is crucial for achieving a consistent and durable finish.

- Fast Heat-Up Times: Gas ovens typically heat up faster than electric ovens, reducing cycle times and increasing productivity.

Diesel Powder Coating Oven

A Diesel Powder Coating Oven is similar to a gas oven but is powered by diesel fuel. These ovens are often used in situations where:

- Fuel Availability: Diesel may be more readily available or more economical than gas in certain regions or for certain operations.

- High-Temperature Requirements: Diesel ovens are capable of reaching high temperatures quickly, making them suitable for heavy-duty applications.

- Portability: Some diesel ovens are designed to be portable, allowing them to be moved to different locations as needed.

Portable Powder Coating Oven

A Portable Powder Coating Oven is designed for mobility, allowing it to be transported to different job sites or easily repositioned within a workshop. Features include:

- Compact Size: Portable ovens are generally smaller and lighter than stationary models, making them easy to move.

- Versatility: These ovens can be used for a variety of applications, from small parts to on-site repairs and custom jobs.

- Flexibility: They can be powered by different fuel sources, including gas, diesel, or electricity, depending on the specific model.

Alloy Wheel Powder Coating

Alloy Wheel Powder Coating is a specialized process designed to coat alloy wheels with a durable and attractive finish. The process involves:

- Preparation: The wheels are first cleaned and prepped to ensure the powder coating adheres properly.

- Application: A powder coating is applied evenly across the wheel, often using a Small Powder Coating Booth to contain the process.

- Curing: The coated wheels are then placed in an oven, where the powder is cured to form a hard, protective layer. This can be done in a Small Powder Coating Oven.

- Finishing: The final product is a wheel with a high-quality finish that resists chips, scratches, and corrosion.

Small Powder Coating Booth and Oven

A Small Powder Coating Booth and Oven setup is ideal for businesses or hobbyists who need to coat small parts efficiently. This setup typically includes:

- A Compact Booth: The booth is designed to fit in smaller spaces while still providing the necessary environment for powder coating.

- A Small Oven: The oven is sized to match the booth, ensuring that parts can be cured immediately after coating, reducing handling and the risk of contamination.

- Integrated Systems: Some setups may combine the booth and oven into a single unit, making it easier to manage the process in a limited space.

Small Powder Coating Oven

A Small Powder Coating Oven is specifically designed for curing smaller items. Key benefits include:

- Space Efficiency: These ovens are designed to fit into smaller workshops or production areas, making them ideal for limited-space environments.

- Quick Heat-Up: Smaller ovens generally heat up faster, allowing for shorter cycle times and increased productivity.

- Cost-Effective: Due to their smaller size, these ovens typically consume less energy, making them a more economical option for small businesses or low-volume operations.

Automatic Powder Coating Equipment

Automatic Powder Coating Equipment refers to systems designed to automate the powder coating process, offering numerous advantages:

- Consistency: Automated equipment ensures that each part is coated evenly, reducing variability and ensuring high-quality finishes.

- Efficiency: Automation reduces the time required to coat each part, increasing throughput and reducing labor costs.

- Advanced Features: Many automated systems include features such as programmable control systems, which allow for precise adjustments to coating parameters, and integration with other manufacturing processes, such as pre-treatment and inspection.

Introduction to Powder Coating and Essential Equipment

Powder coating is an advanced finishing process widely recognized for its efficiency, durability, and environmental benefits. Unlike traditional liquid paint, powder coating uses a dry powder that is electrostatically charged and sprayed onto a surface. The coated surface is then cured under heat, forming a robust and protective layer. This process is employed across various industries, including automotive, aerospace, and consumer goods, due to its superior finish quality and resistance to wear and corrosion.

The success of powder coating depends heavily on the equipment used throughout the process. Powder Coating Equipment includes a wide range of machinery designed to ensure that the powder is applied evenly and cured properly. This equipment encompasses spray guns, booths, ovens, and automated systems that work together to deliver a consistent, high-quality finish. Each piece of equipment serves a specific purpose, and understanding their functions and benefits is crucial for optimizing the powder coating process.

Powder Coating Equipment: A Comprehensive Overview

Powder Coating Equipment refers to the complete set of tools and machinery used in the powder coating process. This equipment includes:

- Electrostatic Spray Guns: These are the primary tools used to apply powder to the substrate. The spray gun charges the powder particles, causing them to adhere to the surface of the part being coated. There are different types of spray guns, including manual and automated versions, each suited for specific applications.

- Powder Coating Booths: These enclosures provide a controlled environment for applying the powder, ensuring that overspray is contained and that the powder is applied uniformly. The booths are designed to maximize efficiency and minimize waste, often incorporating filtration systems to capture excess powder for reuse.

- Curing Ovens: Once the powder has been applied, the coated part is transferred to a curing oven. These ovens heat the part to the required temperature, causing the powder to melt and flow into a smooth, even coating. Different types of ovens, such as gas, diesel, and portable ovens, are used depending on the size of the part and the specific needs of the operation.

- Automated Systems: In larger-scale operations, Automatic Powder Coating Equipment is often used to streamline the process. These systems can automate the entire powder coating process, from powder application to curing, improving efficiency and consistency.

The Role of Powder Coating Booths

A Powder Coating Booth is an essential component of the powder coating process, providing a dedicated space for the application of powder coatings. These booths are designed to create an optimal environment for powder application, with features that include:

- Controlled Airflow: Proper airflow is critical in a powder coating booth. It ensures that the powder particles are evenly distributed and that overspray is captured efficiently. The airflow is carefully managed to prevent contamination and to ensure that the powder adheres uniformly to the substrate.

- Containment of Overspray: A key function of the booth is to contain overspray, preventing powder from spreading to other areas of the workspace. This not only keeps the work environment clean but also allows for the recovery and reuse of overspray, reducing waste and saving on material costs.

- Variety of Configurations: Powder coating booths come in various configurations to suit different applications. For example, walk-in booths are used for coating large parts, while compact booths are ideal for smaller operations.

Small Powder Coating Booth: Efficiency in Compact Spaces

A Small Powder Coating Booth is specifically designed for operations with limited space or for businesses that focus on coating smaller parts. Despite their size, these booths offer several advantages:

- Space-Saving Design: The compact size of a small powder coating booth makes it ideal for workshops or production areas where space is at a premium. These booths are designed to fit into tight spaces without compromising on performance or safety.

- Cost-Effective Operation: Small booths typically require less energy and resources to operate, making them a cost-effective option for small businesses or for coating small batches of parts. They are also easier to install and maintain, reducing overall operating costs.

- Versatility: These booths can handle a wide range of coating tasks, from small automotive parts to prototypes and custom jobs. Their versatility makes them a popular choice for businesses that require flexibility in their operations.

Powder Coating Spray Booth: Optimized for Precision Application

A Powder Coating Spray Booth is a specialized booth designed to optimize the spray application of powder coatings. These booths are equipped with advanced features that enhance the coating process:

- High-Efficiency Filtration Systems: The filtration systems in a spray booth are designed to capture overspray and remove airborne particles, ensuring a clean environment for powder application. This is crucial for achieving a high-quality finish and for maintaining a safe work environment.

- Adjustable Airflow: The airflow in a spray booth can be adjusted to suit the specific requirements of the coating job. This allows for precise control over the application process, ensuring that the powder is applied evenly and with the desired thickness.

- Operator-Friendly Design: Spray booths are designed with the operator in mind, providing easy access to the parts being coated and ergonomic features that reduce fatigue. This improves both the efficiency and safety of the coating process.

Powder Paint Booth with Filters: Ensuring Quality and Safety

A Powder Paint Booth with Filters is a critical component of the powder coating process, providing an enclosed space for the application of powder coatings while ensuring that air quality is maintained. The filtration system in these booths serves several important functions:

- Air Quality Control: The filters in a powder paint booth are designed to capture airborne powder particles, preventing them from contaminating the workspace and ensuring that the air remains clean and breathable. This is particularly important in environments where multiple coating operations are taking place simultaneously.

- Waste Reduction: By capturing overspray, the filtration system helps to reduce waste, as the collected powder can often be recycled and reused. This not only reduces material costs but also minimizes the environmental impact of the coating process.

- Compliance with Regulations: Powder paint booths with filters are often required to meet specific safety and environmental regulations, particularly in industries where hazardous materials are used. The filtration system ensures that the booth operates within these guidelines, protecting both workers and the environment.

Automated Powder Coating System: Enhancing Productivity and Consistency

An Automated Powder Coating System integrates various components of the powder coating process into a fully automated workflow. These systems are designed to improve productivity, consistency, and efficiency in large-scale operations. Key features include:

- Conveyor Systems: Automated systems often incorporate conveyor belts that transport parts through the different stages of the coating process. This allows for continuous production, reducing downtime and increasing throughput.

- Robotic Spray Guns: Robotic arms equipped with spray guns can apply powder coatings with a high degree of precision, ensuring that each part is coated uniformly. This reduces the risk of defects and improves the overall quality of the finish.

- Real-Time Monitoring and Control: Advanced sensors and control systems monitor the coating process in real-time, adjusting parameters as needed to maintain optimal conditions. This ensures consistent results, even in high-volume production environments.

- Scalability: Automated powder coating systems can be scaled to meet the needs of different production volumes, from small batches to large-scale manufacturing. This makes them a versatile solution for a wide range of industries.

Gas Powder Coating Oven: Reliable and Efficient Curing

A Gas Powder Coating Oven is a critical piece of equipment in the powder coating process, providing the heat necessary to cure the powder coating and form a durable, protective layer. These ovens are powered by natural gas and offer several advantages:

- Energy Efficiency: Gas ovens are known for their energy efficiency, as they can heat up quickly and maintain a consistent temperature with minimal energy consumption. This makes them a cost-effective option for large-scale operations.

- Uniform Heating: The design of gas ovens ensures that heat is distributed evenly throughout the oven, preventing hot spots and ensuring that all parts are cured uniformly. This is essential for achieving a consistent, high-quality finish.

- Flexible Operation: Gas powder coating ovens can be used for a wide range of applications, from small parts to large assemblies. They are also available in various sizes and configurations, making them adaptable to different production needs.

Diesel Powder Coating Oven: Power and Portability

A Diesel Powder Coating Oven is similar to a gas oven but is powered by diesel fuel. These ovens are often used in situations where gas is not readily available or where diesel is more economical. The key benefits of diesel ovens include:

- High Heat Output: Diesel ovens are capable of reaching high temperatures quickly, making them ideal for heavy-duty applications that require fast curing times.

- Portability: Many diesel ovens are designed to be portable, allowing them to be easily moved to different locations as needed. This makes them a flexible option for businesses that need to perform coating operations on-site or in remote locations.

- Durability: Diesel ovens are built to withstand harsh conditions and are often used in industrial settings where durability and reliability are critical.

Portable Powder Coating Oven: Versatility on the Move

A Portable Powder Coating Oven offers the flexibility of being moved to different job sites or repositioned within a workshop. These ovens are ideal for operations that require mobility or for businesses with limited space. Key features of portable ovens include:

- Compact and Lightweight Design: Portable ovens are designed to be easily transported, with a compact size and lightweight construction that makes them easy to move and set up.

Powder Coating Spray Booth: Achieving Clean, Efficient, and High-Quality Coating Results

The powder coating process requires a controlled environment to ensure consistent and high-quality finishes. One of the most critical components in this process is the powder coating spray booth, where the actual application of powder takes place. Spray booths provide a dedicated space for applying powder, preventing contamination, capturing overspray, and ensuring that the process is both efficient and environmentally friendly.

Powder coating spray booths are designed to contain the powder within a specific area, keeping it from escaping into the surrounding workspace. These booths are typically equipped with air filtration and extraction systems that capture excess powder particles, reducing waste, minimizing health risks to workers, and maintaining a clean workspace. Additionally, the booth’s environment is controlled to ensure that no contaminants interfere with the powder coating process, resulting in smooth, durable finishes.

EMS Powder Coating Equipment is a trusted manufacturer of powder coating spray booths, offering a wide range of booths equipped with advanced filtration and ventilation systems. EMS spray booths are designed for optimal efficiency, safety, and cleanliness, making them an ideal choice for businesses looking to enhance their powder coating operations. In this guide, we’ll explore how powder coating spray booths work, their benefits, and why EMS Powder Coating Equipment is the best option for businesses seeking high-performance booths.

What is a Powder Coating Spray Booth?

A powder coating spray booth is an enclosed space where powder is applied to products during the powder coating process. The booth provides a controlled environment that prevents external contaminants from affecting the coating process while also containing the powder within a specific area to prevent it from spreading throughout the workspace. These booths are an essential part of any powder coating system, as they ensure a clean, safe, and efficient application process.

How Powder Coating Spray Booths Work

In a powder coating spray booth, products are placed inside the booth and coated using electrostatic spray guns. These guns charge the powder particles, which are then attracted to the grounded surface of the product. This electrostatic attraction ensures that the powder adheres evenly to the product, providing a smooth and consistent coat.

As the powder is applied, some particles may not adhere to the product and become airborne. To prevent these excess particles from escaping into the surrounding workspace, the booth is equipped with an air extraction and filtration system. This system draws air through filters that capture the excess powder, keeping the air inside the booth clean and free from harmful particulates.

Many powder coating spray booths are equipped with features like adjustable airflow, which allows operators to control the speed and direction of air movement within the booth. This helps ensure that the powder is applied evenly and that overspray is efficiently captured and recycled, minimizing waste.

EMS Powder Coating Equipment manufactures spray booths with advanced air filtration and extraction systems that maximize efficiency and cleanliness. Their booths are designed to handle the demands of industrial powder coating operations, ensuring consistent and high-quality results.

The Benefits of Powder Coating Spray Booths

Powder coating spray booths are essential for businesses looking to improve the efficiency, safety, and quality of their powder coating process. Here are some of the key benefits of using a high-quality spray booth:

1. Improved Product Quality

A controlled environment is essential for achieving consistent, high-quality finishes in powder coating. In an open workspace, contaminants such as dust, dirt, or debris can settle on the product during the coating process, leading to defects like uneven finishes or poor adhesion. A powder coating spray booth provides a clean, enclosed space where products can be coated without the risk of contamination from the outside environment.

In addition to preventing contamination, the airflow and filtration system inside the booth ensure that overspray is effectively captured, preventing it from interfering with the final finish. The result is a smooth, even coating that meets the highest standards of quality and durability.

EMS Powder Coating Equipment designs its spray booths to provide a clean, controlled environment that enhances the quality of the finished product. Their booths are engineered for precision, ensuring that each product receives a flawless coating.

2. Reduced Powder Waste and Cost Savings

Powder waste is a common issue in powder coating operations, especially when the excess powder is not properly captured and recycled. Without a spray booth, much of the overspray can be lost, leading to higher material costs and environmental waste. Powder coating spray booths are designed to capture excess powder, allowing it to be collected and reused.

The filtration system in a spray booth traps airborne powder particles and prevents them from escaping into the workspace. This captured powder can then be reclaimed and reintroduced into the coating process, reducing material waste and cutting costs.

EMS Powder Coating Equipment offers spray booths with advanced powder recovery systems that maximize powder reuse and minimize waste. Their booths are designed to reduce material costs by ensuring that as much powder as possible is captured and recycled.

3. Enhanced Worker Safety

Worker safety is a top priority in any industrial setting, and powder coating operations are no exception. During the powder coating process, airborne powder particles can pose a respiratory hazard to workers if they are not properly contained. Inhaling these particles over time can lead to respiratory issues and other health problems.

Powder coating spray booths are equipped with ventilation and filtration systems that remove harmful particulates from the air, ensuring that the workspace remains clean and safe for operators. The booth’s design prevents airborne powder from escaping into the surrounding environment, reducing the risk of exposure for workers.

EMS Powder Coating Equipment designs its spray booths with safety in mind, offering advanced filtration and ventilation systems that protect workers from inhaling harmful particles. Their booths are built to meet the highest safety standards, ensuring a safe and healthy work environment.

4. Environmental Compliance

Many industries are subject to strict environmental regulations regarding air quality and emissions. Powder coating is an environmentally friendly process compared to liquid painting, as it produces minimal volatile organic compounds (VOCs). However, without proper containment and filtration, excess powder can still be released into the atmosphere, contributing to air pollution.

Powder coating spray booths are designed to contain and capture overspray, preventing it from being released into the environment. The booth’s filtration system ensures that any excess powder is collected and safely disposed of or recycled, helping businesses meet environmental regulations and reduce their overall environmental impact.

EMS Powder Coating Equipment offers spray booths with high-performance filtration systems that help businesses comply with environmental standards. Their booths are designed to minimize emissions and improve sustainability in powder coating operations.

5. Flexibility and Customization

Powder coating spray booths come in a variety of sizes and configurations, making them suitable for different types of products and production volumes. Whether you’re coating small parts or large industrial components, spray booths can be customized to meet the specific needs of your operation. This flexibility allows businesses to optimize their coating process for efficiency and quality.

Spray booths can also be equipped with additional features, such as adjustable airflow controls, automated powder recovery systems, and more, to enhance performance and meet the unique requirements of each production line.

EMS Powder Coating Equipment provides customizable spray booths that can be tailored to the specific needs of your business. Whether you need a small batch booth or a large conveyorized system, EMS offers solutions that ensure optimal performance and efficiency.

6. Easy Maintenance and Long-Term Reliability

A high-quality spray booth is a long-term investment that can provide years of reliable performance with proper maintenance. Regularly replacing filters and cleaning the booth ensures that it continues to operate efficiently and that air quality remains high. High-quality spray booths are built to withstand the demands of continuous industrial use, providing businesses with a durable solution for their powder coating needs.

EMS Powder Coating Equipment manufactures spray booths that are designed for ease of maintenance and long-lasting reliability. Their booths are constructed from high-quality materials that resist wear and tear, ensuring that your investment will continue to deliver top-tier performance for years to come.

Why Choose EMS Powder Coating Equipment for Spray Booths?

When selecting a powder coating spray booth, businesses need equipment that offers precision, efficiency, and durability. EMS Powder Coating Equipment is the industry leader in providing advanced spray booths that meet the highest standards of performance and safety. Here’s why EMS is the best choice for businesses looking to invest in high-quality spray booths:

1. Advanced Filtration and Ventilation Technology

EMS spray booths are equipped with cutting-edge filtration and ventilation systems that ensure a clean, safe environment for both workers and products. Their booths are designed to capture excess powder with maximum efficiency, preventing contamination and improving air quality in the workspace.

2. Customizable Solutions for Different Industries